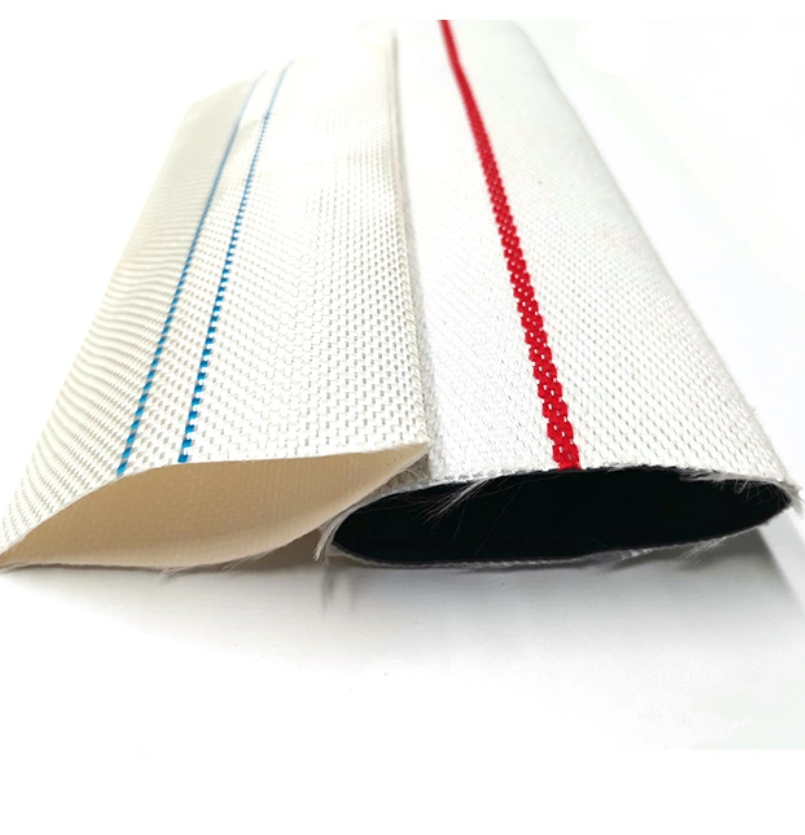

High-Quality 8x5mm Polyurethane Tubing for Versatile Applications in Fluid Transport and Manufacturing

Understanding 8x5mm Polyurethane Tubing Applications and Benefits

Polyurethane tubing has gained immense popularity across various industries due to its versatile properties and performance capabilities. Among the many sizes available in the market, the 8x5mm polyurethane tubing has become a preferred choice for numerous applications. This article explores the characteristics, benefits, and common uses of this specific tubing size.

Characteristics of 8x5mm Polyurethane Tubing

The designation 8x5mm indicates that the tubing has an outer diameter of 8mm and an inner diameter of 5mm. Made from high-quality polyurethane, this tubing exhibits remarkable elasticity, flexibility, and resilience. Polyurethane is a thermoplastic material, which means it can be molded into various shapes and sizes when heated, making it ideal for producing tubing that meets specific requirements.

One of the most notable characteristics of polyurethane tubing is its abrasion resistance. This feature allows it to withstand wear and tear, which is crucial in environments where the tubing may be subject to friction from surrounding surfaces. Additionally, the material is resistant to a variety of chemicals, including oils and solvents, making it suitable for applications in industries such as automotive, manufacturing, and food processing.

Benefits of Using 8x5mm Polyurethane Tubing

1. Flexibility and Durability The inherent flexibility of polyurethane tubing ensures that it can bend and curve without breaking, which is vital for applications requiring dynamic movement. This flexibility, combined with its durability, allows for reliable use in challenging environments.

2. Lightweight Compared to metal or rubber tubing, polyurethane tubing is significantly lighter, which can lead to easier handling and installation. This lightweight nature also reduces the overall weight of the assembled product, enhancing portability and ease of operation.

3. Excellent Flow Characteristics The smooth inner surface of 8x5mm polyurethane tubing promotes efficient fluid flow, reducing the risk of clogging. This property is particularly beneficial in applications involving the transportation of liquids or gases.

4. Wide Temperature Range Polyurethane tubing can perform effectively in a wide range of temperatures, typically from -30°C to 80°C (-22°F to 176°F). This feature makes it suitable for various environments, from cold storage to heated industrial processes.

8x5mm polyurethane tubing

5. Reduced Maintenance The chemical resistance and durability of polyurethane tubing minimize wear and tear, which can lead to lower maintenance costs over time. This is especially advantageous in high-demand industries where downtime can be costly.

Common Applications

The 8x5mm polyurethane tubing is utilized across a broad spectrum of applications. Here are some common uses

- Pneumatic Systems The tubing is widely used in pneumatic systems for delivering compressed air. Its flexibility allows for easy routing in complex machinery setups.

- Automotive In the automotive industry, the 8x5mm tubing is often employed in fuel lines and fluid transfer systems due to its resistance to oils and fuels.

- Medical Devices Its biocompatibility and flexibility make polyurethane tubing suitable for various medical applications, including IV lines and catheter systems.

- Food and Beverage The tubing's resistance to chemicals and ease of cleaning make it ideal for food and beverage processing, where hygiene and safety are paramount.

- Robotics and Automation The lightweight and flexible properties of this tubing enhance the performance of robotic arms and automated systems, allowing for precise movements and reduced fatigue over time.

Conclusion

In conclusion, 8x5mm polyurethane tubing is a versatile and robust solution for various industrial applications. Its unique combination of flexibility, durability, and chemical resistance makes it an invaluable asset for industries ranging from automotive to medical. As technology advances and industries evolve, the demand for quality tubing like the 8x5mm polyurethane variety is expected to grow, cementing its place as a crucial component in modern manufacturing and engineering solutions.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025