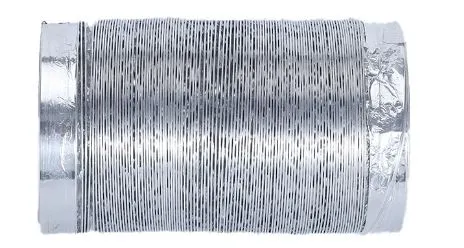

Flexible Aluminum Foil Duct - Durable HVAC & Dryer Venting

The Indispensable Role of Aluminum Foil Duct in Modern Ventilation Systems

In an era where efficient air management is paramount, the demand for high-performance ventilation solutions continues to surge across diverse industries. Among the array of options, the aluminum foil duct stands out as a versatile and cost-effective choice for air conveyance. This article delves into the technical intricacies, application diversity, and strategic advantages of modern flexible ducting solutions, specifically focusing on the advanced capabilities of products like the Range Hood Exhaust Pipe Aluminum Foil Flexible Pipe Ventilation Pipe. We aim to provide a comprehensive overview for B2B decision-makers and technical professionals, ensuring a clear understanding of its value proposition in demanding environments.

The global market for flexible ducting is experiencing robust growth, driven by increasing construction activities, stringent indoor air quality regulations, and the expanding need for efficient HVAC systems in residential, commercial, and industrial sectors. Emerging trends highlight a preference for materials that offer excellent thermal insulation, superior corrosion resistance, and ease of installation. Flexible aluminum foil duct specifically addresses these requirements, offering a lightweight yet durable solution for various ventilation and exhaust applications, contributing significantly to energy efficiency and operational safety.

Understanding Aluminum Foil Duct: Technical Parameters and Industry Standards

A critical aspect of selecting the appropriate ventilation conduit involves a thorough understanding of its technical specifications and compliance with industry benchmarks. Aluminium foil flexible duct is engineered to meet a wide range of operational demands, characterized by parameters such as diameter, temperature rating, pressure resistance, and fire safety classifications. Adherence to standards like UL 181 Class 1 for air ducts ensures a product's integrity and safety in various installations. These ducts are often constructed from multiple layers of aluminum foil and polyester film, reinforced with a high-tensile steel wire helix, providing an optimal balance of flexibility and structural stability.

The design of aluminum foil hose allows for significant compressibility, reducing shipping and storage costs, while also offering excellent bend radius capabilities without crimping, which is crucial for navigating complex installations. Its smooth inner surface minimizes airflow resistance, thereby enhancing system efficiency and reducing energy consumption. Below is a table detailing typical technical parameters for high-quality aluminum foil flexible ducts:

Typical Aluminum Foil Duct Specifications

| Parameter | Typical Range/Value | Significance |

|---|---|---|

| Diameter Range | 4" to 24" (100mm to 600mm) | Versatility for various airflow requirements. |

| Temperature Range | -20°C to +120°C (-4°F to +250°F) | Suitability for hot and cold air conveyance. |

| Max. Operating Pressure | 2500 Pa (10 in. w.g.) | Resistance to internal system pressures. |

| Air Velocity | Max. 30 m/s (6000 ft/min) | Capacity for high-speed airflow. |

| Material Composition | Multi-ply Aluminum Foil & PET Film, Steel Wire Helix | Durability, flexibility, and anti-corrosion properties. |

| Fire Rating | UL 181 Class 1 (Flame Spread 0, Smoke Developed 0) | Ensures safety in building applications. |

| Service Life | Typically 10-15 years under normal conditions | Long-term reliability and reduced replacement costs. |

The Manufacturing Process of High-Quality Flexible Aluminum Foil Duct

The production of high-grade flexible aluminum foil duct involves a sophisticated sequence of steps, ensuring the final product meets stringent performance and durability requirements. Unlike rigid ducts that may involve casting or CNC machining, the manufacturing of flexible ducts centers on lamination, spiraling, and precision crimping techniques. The process begins with sourcing high-purity aluminum foil and polyester film, chosen for their inherent resistance to corrosion and excellent thermal properties. These materials are then expertly laminated to create a multi-layered barrier, enhancing strength and preventing air leakage.

A key step is the spiral winding of the laminated material around a high-tensile steel wire helix. This core provides the structural integrity and flexibility for which the aluminum foil duct is renowned. Advanced machinery ensures precise tension and consistent pitch of the helix, which directly impacts the duct's crush resistance and bend radius. Each stage of manufacturing, from raw material inspection to final product assembly, undergoes rigorous quality control. This includes testing for burst pressure, tensile strength, air leakage rates, and flame propagation, ensuring compliance with international standards such as ISO 9001 for quality management and specific product standards like ASTM E84 for surface burning characteristics. This meticulous process guarantees a product with exceptional service life, typically exceeding 10-15 years under appropriate operating conditions, and robust performance in environments where energy efficiency and corrosion resistance are paramount.

Diverse Applications and Key Advantages of Aluminum Foil Duct

The inherent flexibility, lightweight nature, and robust performance of flexible aluminum foil duct make it an ideal choice across a myriad of applications, extending far beyond conventional HVAC systems. From industrial ventilation to specialized exhaust systems, its adaptability ensures optimal air handling. In the commercial kitchen sector, particularly for range hood exhaust, the specific design of products like the Range Hood Exhaust Pipe Aluminum Foil Flexible Pipe Ventilation Pipe facilitates efficient removal of smoke, grease, and odors, directly contributing to improved indoor air quality and compliance with health and safety regulations.

Beyond kitchens, aluminium foil flexible duct finds extensive use in various industrial settings for fume extraction, dust collection, and general ventilation. Its corrosion-resistant properties are particularly beneficial in environments with chemical vapors or high humidity, safeguarding the system's longevity and performance. The material's low thermal conductivity also contributes to energy savings by minimizing heat loss or gain during air transfer, a significant advantage in both heated and cooled environments. The ease of installation, requiring fewer fittings and less labor compared to rigid ductwork, further reduces overall project costs and timelines.

- Energy Efficiency: The multi-ply construction and low air resistance lead to reduced fan energy consumption.

- Corrosion Resistance: Aluminum's inherent properties provide excellent protection against moisture and chemical agents.

- Flexibility & Ease of Installation: Accommodates tight spaces and complex routing, significantly cutting installation time and labor.

- Durability & Longevity: Reinforced with a steel helix, ensuring structural integrity and a long service life.

- Cost-Effectiveness: Lower material and installation costs compared to rigid alternatives.

Choosing the Right Supplier: Manufacturer Comparison and Customization Solutions

Selecting a reliable manufacturer for aluminum foil duct is paramount to ensuring product quality, performance, and long-term cost-effectiveness. Key factors to consider include the manufacturer's adherence to international standards, their production capacity, R&D capabilities, and the extent of their customization offerings. Leading manufacturers, such as Kebing Hose, distinguish themselves through their commitment to innovation, consistent quality assurance processes, and comprehensive customer support.

Kebing Hose, with years of specialized experience in hose and duct manufacturing, offers tailored solutions for diverse industrial requirements. Our expertise extends to providing customized diameters, lengths, temperature ratings, and specific material compositions to meet unique project specifications. This bespoke approach ensures that clients receive an aluminum foil hose perfectly engineered for their application, whether it's for a high-volume industrial exhaust system or a specialized laboratory ventilation setup. This level of customization, coupled with stringent manufacturing controls and an ISO 9001 certified quality management system, positions Kebing Hose as a trusted partner for B2B procurement.

Real-World Impact: Application Case Studies with Flexible Aluminum Foil Duct

The practical efficacy of aluminum foil duct is best demonstrated through its successful deployment in challenging real-world scenarios. For instance, a major restaurant chain faced significant challenges with grease accumulation and poor smoke extraction in their kitchens using traditional rigid ductwork due to complex routing requirements. By transitioning to the Range Hood Exhaust Pipe Aluminum Foil Flexible Pipe Ventilation Pipe, they achieved a 30% improvement in exhaust efficiency, reduced installation time by 40%, and significantly mitigated fire risks associated with grease buildup, thanks to the smooth inner surface and ease of cleaning.

Another compelling case involved a large manufacturing facility needing to vent abrasive dust from multiple workstations to a central filtration unit. Traditional rigid metal ducts were prone to wear and difficult to reconfigure. By implementing heavy-duty flexible aluminum foil duct, the facility not only achieved a more adaptable system layout but also experienced a noticeable reduction in system noise and vibration, improving the overall working environment. These examples underscore the versatility and performance benefits that aluminum foil hose brings to complex industrial and commercial ventilation challenges, showcasing its ability to deliver superior performance and operational benefits.

Ensuring Trust: Quality Assurance, Delivery, and Customer Support

Trustworthiness is the cornerstone of B2B relationships. At Kebing Hose, our commitment to quality is underpinned by rigorous testing protocols and adherence to global standards. Every batch of aluminium foil flexible duct undergoes comprehensive quality checks, including air leakage tests, material thickness verification, and dimensional accuracy, ensuring that each product meets the stated specifications and performance guarantees. Our manufacturing facilities are ISO 9001 certified, reflecting our dedication to consistent quality management systems from raw material sourcing to final packaging. This unwavering commitment to quality ensures a product you can rely on for critical applications.

Understanding the critical importance of timely project completion, we have optimized our supply chain and logistics to offer reliable delivery schedules. Typical lead times for standard products range from 7-14 business days, with expedited options available for urgent requirements. Custom orders are managed with transparent timelines, ensuring clients are fully informed throughout the production and delivery process. Furthermore, all our aluminum foil duct products are backed by a comprehensive 12-month warranty against manufacturing defects, providing peace of mind and demonstrating our confidence in product durability. Our dedicated technical support team is available to assist with product selection, installation guidance, and troubleshooting, ensuring seamless integration and optimal performance in your systems.

Frequently Asked Questions (FAQ) about Aluminum Foil Duct

-

Q: What is the primary advantage of flexible aluminum foil duct over rigid ducting?

A: The main advantage lies in its flexibility, which allows for easier installation in confined spaces or around obstacles without the need for multiple fittings, reducing labor and material costs. It also offers excellent compressibility for transportation efficiency. -

Q: Is aluminum foil duct suitable for high-temperature applications?

A: Yes, standard aluminum foil duct can withstand temperatures typically up to 120°C (250°F), making it suitable for range hood exhausts, dryer vents, and general industrial ventilation. For higher temperatures, specialized high-temp flexible ducts are available. -

Q: How does the steel wire helix contribute to the duct's performance?

A: The embedded steel wire helix provides structural integrity and crush resistance, allowing the duct to maintain its circular shape even under negative pressure or minor external forces. It enables the duct to be extended and retracted repeatedly without damage. -

Q: What are the typical delivery times for large orders of aluminum foil hose?

A: For standard products, typical delivery is 7-14 business days after order confirmation. For large volume or customized orders, lead times are discussed and confirmed during the quotation process, but we strive for efficient turnaround. -

Q: What warranty is offered on your aluminum foil duct products?

A: We offer a 12-month warranty against manufacturing defects from the date of purchase. This warranty covers material and workmanship failures under normal operating conditions and proper installation.

Authoritative References

- ASHRAE Handbook—Fundamentals, Chapter 21: Duct Design. American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- International Mechanical Code (IMC) - Chapter 6, Duct Systems. International Code Council.

- UL 181: Standard for Factory-Made Air Ducts and Air Connectors. Underwriters Laboratories.

- ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials. ASTM International.

- ISO 9001: Quality management systems — Requirements. International Organization for Standardization.

-

Utilizing Braided Pvc Hose For Construction PurposesNewsAug.11,2025

-

The Flexibility of Lpg Gas Hose in Low-Temperature ApplicationsNewsAug.11,2025

-

Reinforced Layers in Clear Reinforced PVC HoseNewsAug.11,2025

-

How Hose Braiding Benefits Fluid TransferNewsAug.11,2025

-

Flexible Suction Hose Pipe in Industrial Vacuum CleanersNewsAug.11,2025

-

Chemical Resistance Offered by PVC Tetoron-Reinforced HoseNewsAug.11,2025