Exploring the Benefits and Applications of Foil Ducts in HVAC Systems and Home Insulation

The Advantages and Applications of Foil Ducting in Modern HVAC Systems

In the realm of heating, ventilation, and air conditioning (HVAC) systems, the choice of ducting materials plays a pivotal role in determining the efficiency and effectiveness of air distribution. Among various options available, foil ducting, often made of aluminum or similar materials, has gained prominence for its unique properties and advantages. This article explores the benefits and applications of foil ducting, highlighting why it has become a preferred choice in many modern installations.

What is Foil Ducting?

Foil ducting refers to flexible ductwork that is constructed from layers of aluminum foil and sometimes includes insulation. Its lightweight yet sturdy construction allows for easy handling and installation. Unlike rigid metal ducts, which can be cumbersome and time-consuming to install, foil ducts can be bent, twisted, and routed around obstacles without losing efficiency. This flexibility makes them particularly popular in both residential and commercial HVAC applications.

Key Advantages of Foil Ducting

1. Lightweight and Flexible One of the most significant benefits of foil ducting is its lightweight nature. This feature not only simplifies transportation but also reduces the labor and time needed for installation. Technicians can easily maneuver the ducting to fit into tight spaces, making it ideal for retrofitting existing buildings where rigid ductwork may pose challenges.

2. Excellent Insulation Properties Foil ducting often comes with insulation that helps maintain the temperature of the air being transported. This capability reduces energy loss, enhances system efficiency, and ultimately lowers energy costs. The insulated foil ducting effectively minimizes condensation risk, making it suitable for various climates.

foil duct

3. Corrosion Resistance Aluminum is inherently resistant to rust and corrosion, thus prolonging the lifespan of foil ducting. This feature is particularly advantageous in humid or harsh environments where traditional metal ducts may deteriorate over time. This durability ensures that foil ducts can deliver consistent performance throughout their service life.

Applications of Foil Ducting

1. Residential HVAC Systems In private homes, foil ducting is frequently used in installations where space is limited. It can easily adapt to various layouts, ensuring efficient airflow throughout the house. Its insulation properties make it particularly beneficial in regions with extreme temperatures, helping to optimize heating and cooling systems.

2. Commercial Settings Foil ducting is equally valuable in commercial settings, such as office buildings and shopping malls. Its flexibility allows for quick installation within large spaces, and its ability to support high airflow rates makes it suitable for demanding applications. Additionally, foil ducts can be easily integrated into existing systems, facilitating upgrades or expansions.

3. Industrial Applications In industrial environments, foil ducting is used for exhaust ventilation and fume extraction. Its resistance to corrosion and the ability to withstand various environmental conditions make it ideal for such applications, ensuring effective removal of unwanted gases and particulates.

Conclusion

Foil ducting represents a modern solution that combines flexibility, efficiency, and durability in HVAC systems. Its unique properties not only improve energy efficiency but also simplify installation processes, making it a favored choice among contractors and building owners alike. As the demand for efficient, sustainable HVAC solutions continues to rise, the role of foil ducting is likely to expand, providing effective air distribution alternatives in various residential, commercial, and industrial settings. With its many advantages, foil ducting stands out as a reliable option for meeting the challenges of modern air management systems.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

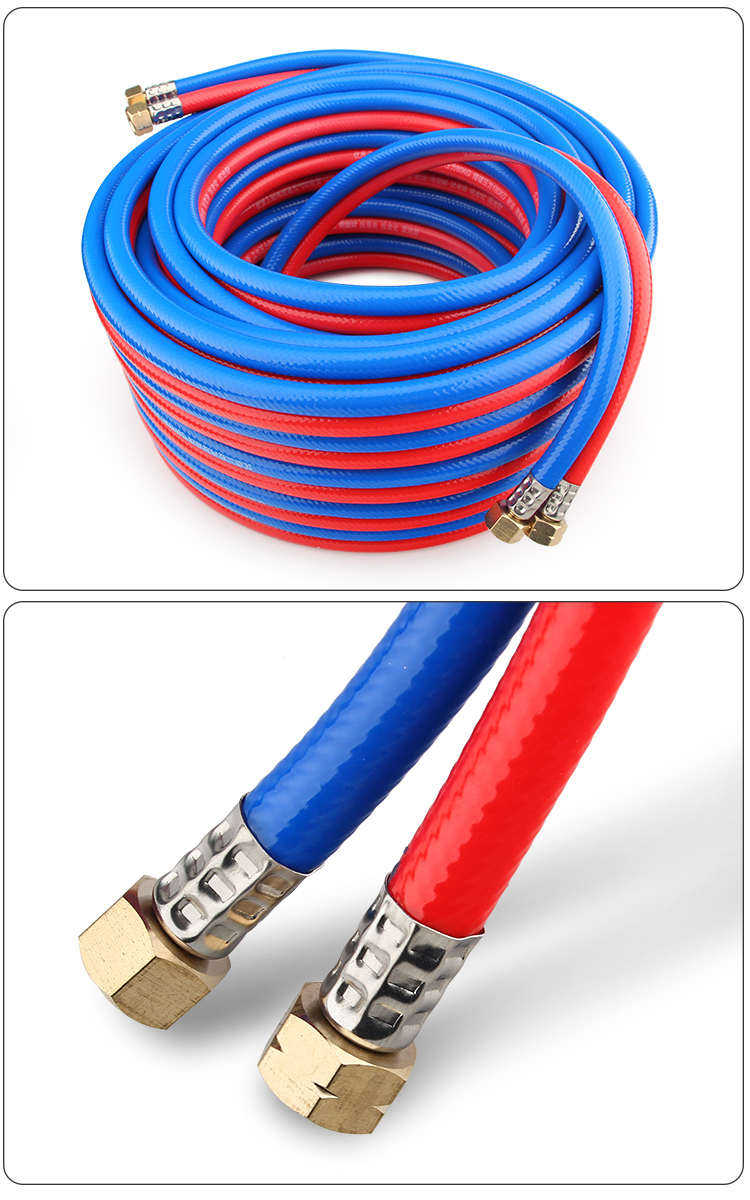

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025