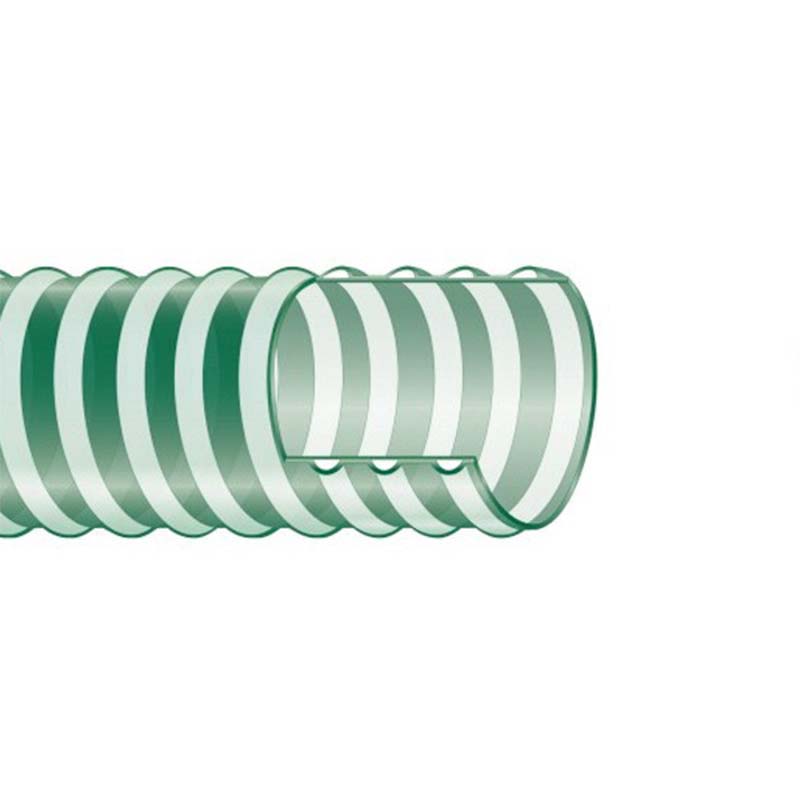

Durable and Lightweight PVC Air Compressor Hose for Efficient Airflow and Versatile Applications

The Benefits of Using PVC Air Compressor Hoses

When it comes to powering tools and equipment in a workshop or construction site, air compressors play a crucial role. One of the essential components that facilitate the efficient transfer of compressed air is the air compressor hose. Among the various options available on the market, PVC (Polyvinyl Chloride) air compressor hoses have gained popularity due to their distinctive properties and advantages.

Durability and Flexibility

PVC air compressor hoses are known for their durability. These hoses are resistant to abrasion, which is essential in environments where they are frequently exposed to rough surfaces. Unlike rubber hoses, PVC hoses do not crack or become less flexible in colder temperatures, making them suitable for a variety of weather conditions. The flexibility of PVC hoses ensures that they can be easily coiled and stored without the risk of kinking or breaking, thus prolonging their lifespan and usability.

Lightweight and Easy to Handle

One of the most significant advantages of PVC air compressor hoses is their lightweight nature. Compared to traditional rubber hoses, PVC options are much lighter, which makes them easier to handle, especially for users who may need to drag them over long distances. This lightweight design reduces fatigue, allowing users to work more efficiently without the added strain of hauling heavy hoses around.

Cost-Effective Solution

When looking to purchase air compressor hoses, cost is often a significant factor. PVC hoses tend to be more affordable than their rubber counterparts, making them a cost-effective solution for both professionals and DIY enthusiasts. The balance of durability and price allows consumers to get the best value for their investment without sacrificing quality.

pvc air compressor hose

Chemical Resistance

Another important characteristic of PVC hoses is their resistance to various chemicals and oils. This property makes them suitable for a wide range of applications beyond just air compression, including gardening, automotive work, and manufacturing processes. The ability to withstand exposure to certain substances without degrading ensures that PVC hoses remain reliable and safe for extended use.

Versatility of Applications

PVC air compressor hoses are incredibly versatile. They can be used for air tool applications, pneumatic systems, and other equipment requiring compressed air. Their adaptability makes them a suitable choice for various industries, including construction, automotive, and agriculture. Users can confidently use PVC hoses with multiple tools, knowing that they can handle the pressure and stress involved in diverse applications.

Easy Maintenance and Cleaning

Maintaining air compressor hoses is critical for their longevity and performance. PVC hoses are relatively easy to clean and maintain. After use, they can be wiped down or rinsed off to remove any dirt or debris. This ease of maintenance adds to their appeal for users who want to keep their equipment in top condition without dedicating extensive time to upkeep.

Conclusion

In summary, PVC air compressor hoses stand out as a practical choice for anyone needing a reliable and efficient solution for compressed air applications. With their durability, flexibility, lightweight design, cost-effectiveness, chemical resistance, and versatility, these hoses cater to a wide array of users, from professionals to hobbyists. Understanding the benefits of PVC air compressor hoses can help consumers make informed decisions, ensuring they select the best tools for their projects. Whether in a workshop or on a job site, investing in a quality PVC air compressor hose can significantly enhance productivity and performance.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025