Flexible Duct Hose Solutions for Efficient Airflow and Ventilation Systems

Understanding Ducting Hose Applications and Benefits

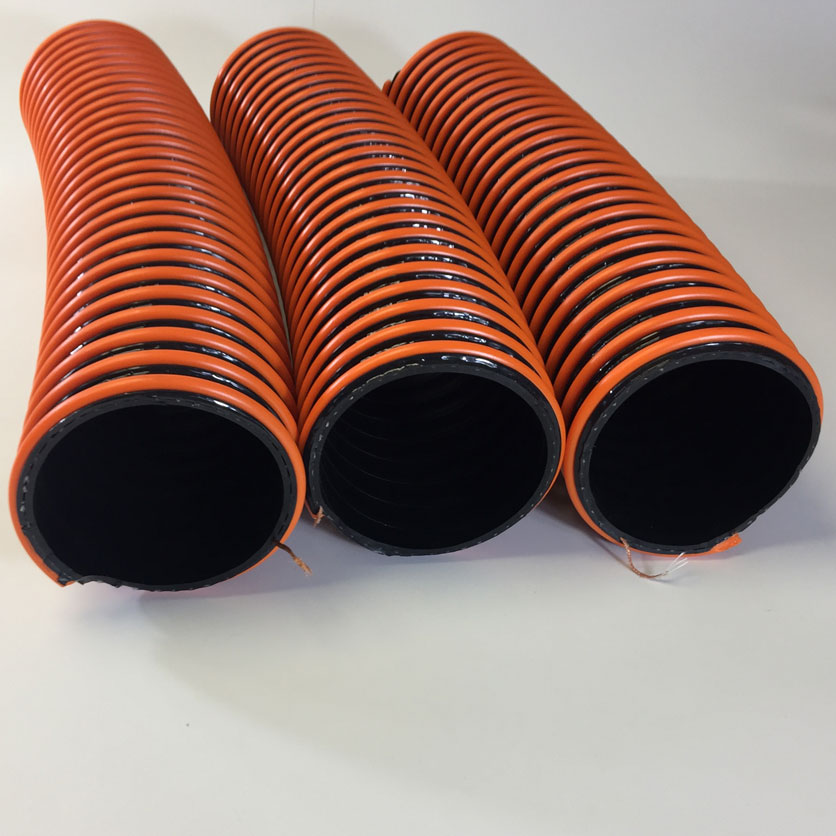

Ducting hose, often referred to as ducting or ventilation hose, is a versatile and essential component in various industrial and commercial applications. It is designed for the efficient transfer of air, gases, and particles, making it a vital tool in settings ranging from manufacturing plants to HVAC systems. This article will explore the different types of ducting hoses, their applications, and the benefits they offer.

What is Ducting Hose?

Ducting hose is typically made from a variety of materials, including PVC, polyurethane, neoprene, and silicone. These materials are chosen based on the specific requirements of the application, such as flexibility, temperature resistance, and chemical compatibility. Ducting hoses come in various diameters, lengths, and designs, providing options for a wide range of uses.

Types of Ducting Hose

1. Flexible Ducting Hose This type is highly adaptable and can be bent or shaped to fit specific spaces. Flexible ducting hoses are commonly used in areas where standard tubing may not fit.

2. Heavy-Duty Ducting Hose Made from robust materials, heavy-duty hoses are designed to withstand abrasive materials, extreme temperatures, and harsh environments. They are frequently employed in industrial settings such as construction sites and mines.

3. High-Temperature Ducting Hose As the name suggests, this type of hose is designed to handle high heat, making it suitable for applications in the automotive and aerospace industries, as well as in foundries and manufacturing plants where high temperatures are prevalent.

4. Fire-Resistant Ducting Hose This hose is constructed using materials that resist ignition and can withstand flames, making it crucial in environments where fire hazards are a concern.

5. Anti-Static Ducting Hose Designed to prevent the buildup of static electricity, anti-static hoses are essential in environments where flammable materials are present, ensuring the safe transfer of gases and particulate matter.

Applications of Ducting Hose

Ducting hoses have a wide range of applications across various industries

- HVAC Systems In heating, ventilation, and air conditioning systems, ducting hoses are used to transport air from one location to another, ensuring efficient climate control in residential and commercial buildings.

ducting hose

- Industrial Vacuum Systems In manufacturing and processing plants, ducting hoses are often part of vacuum systems that remove debris, dust, and other contaminants from the air, maintaining a clean and safe working environment

.- Dust Collection Ducting hoses are commonly employed in woodworking shops and metal fabrication facilities where dust and airborne particles must be effectively collected and eliminated.

- Fume Extraction Hoses designed for fume extraction play a critical role in laboratories and factories by removing hazardous gases and vapors, protecting workers’ health and maintaining compliance with safety regulations.

- Agricultural Uses In agriculture, ducting hoses are used for transporting air, fertilizers, and other materials across farms, often in conjunction with pneumatic systems.

Benefits of Using Ducting Hose

1. Versatility The adaptability of ducting hoses makes them suitable for a variety of applications, accommodating different environments and material handling needs.

2. Efficiency By facilitating the effective transfer of air, gases, and particles, ducting hoses contribute to the overall efficiency of systems, reducing energy consumption and maintaining optimal performance.

3. Safety The use of specialized ducting hoses, such as fire-resistant and anti-static hoses, enhances safety in workplaces by minimizing the risk of fire and static discharge.

4. Durability High-quality ducting hoses are built to withstand harsh conditions, providing longevity and reducing the need for frequent replacements.

5. Cost-Effectiveness Investing in the right ducting hose can minimize maintenance costs and downtime, ultimately leading to savings in operational budgets.

Conclusion

Ducting hose is an indispensable component in various industries, providing solutions for air and material transfer that enhance safety, efficiency, and performance. With the availability of different types tailored to specific applications, businesses can select the most appropriate ducting solutions to meet their operational needs. Understanding the features and benefits of ducting hoses empowers companies to make informed decisions that positively impact their productivity and environmental safety. Whether in HVAC systems, industrial plants, or agricultural setups, ducting hoses play a crucial role in modern operations.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025