ducting hose

Understanding Ducting Hose A Versatile Solution for Air Management

In today’s world, effective airflow management is paramount in numerous industries, from construction sites to manufacturing plants, and even in households. One of the most versatile and essential components in airflow systems is the ducting hose. This flexible tubular device plays a significant role in moving air, dust, and other materials throughout various setups, making it an indispensable tool across many applications.

What is a Ducting Hose?

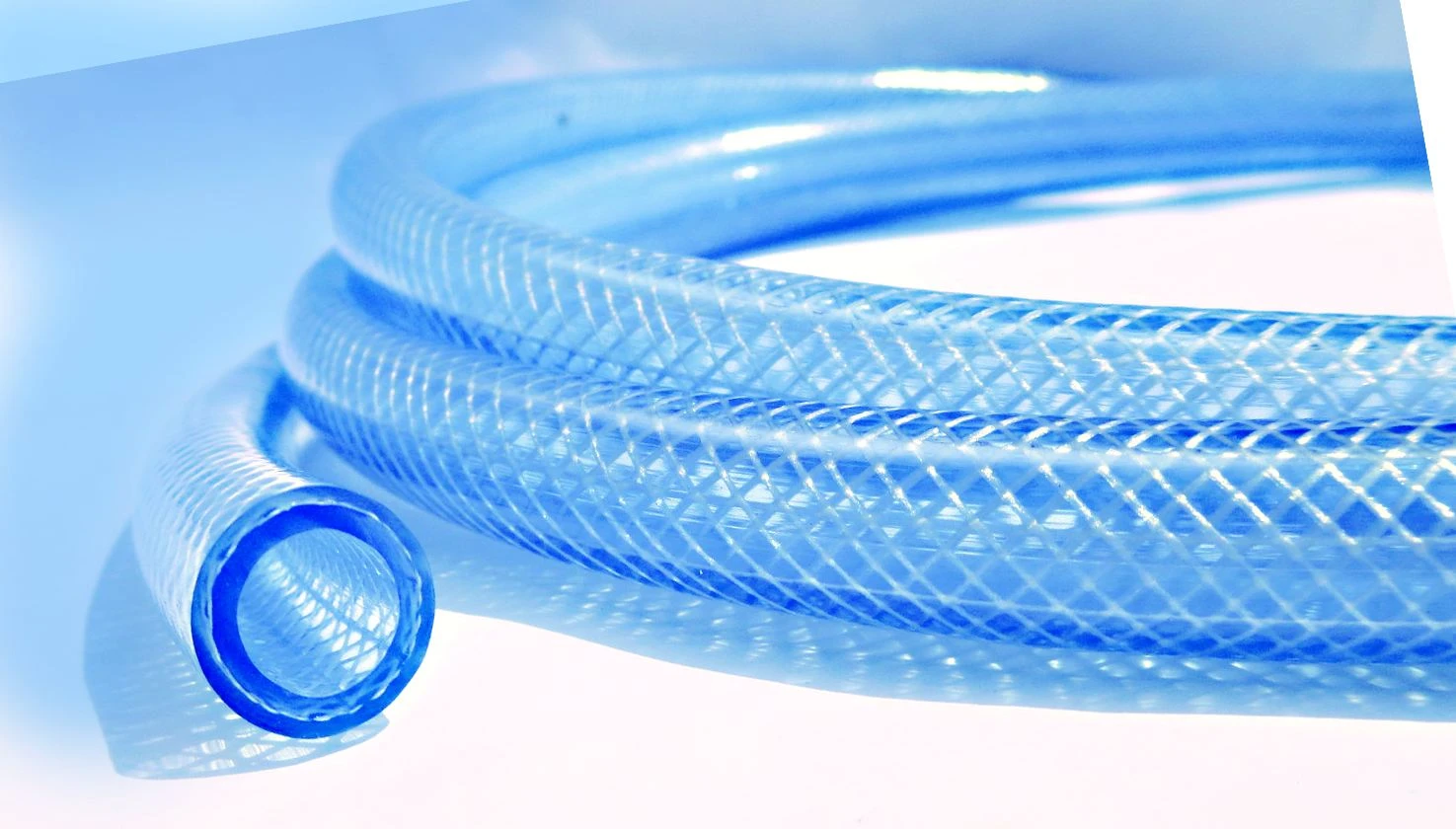

A ducting hose is a flexible tube that is designed to transport air and materials under various conditions. It is typically made from durable and lightweight materials such as PVC, polyurethane, and aluminum. The construction allows these hoses to be highly adaptable, accommodating different sizes and shapes for specific needs. Their flexibility enables them to be installed in tight spaces and to navigate around obstacles, which is crucial in many industrial and commercial environments.

Applications of Ducting Hose

Ducting hoses find applications in a wide range of sectors

1. Industrial Settings In manufacturing and construction, ducting hoses are utilized for dust collection and fume extraction systems. They efficiently transport harmful particles away from the work area, ensuring a safer environment for employees. Whether it's removing wood dust, metal shavings, or welding fumes, these hoses help in maintaining air quality.

2. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, ducting hoses are used to distribute conditioned air throughout buildings. They facilitate effective air circulation, ensuring that spaces are adequately cooled or heated. Different types of ducting hoses are selected based on the specific requirements of the HVAC system and the layout of the building.

3. Agriculture In the agricultural sector, ducting hoses are utilized for ventilation in greenhouses and livestock facilities. They help maintain optimal conditions for plants and animals, ensuring healthy growth and productivity. Proper airflow is crucial in preventing mold growth and maintaining humidity levels.

4. Home Use Homeowners also benefit from ducting hoses in various applications, such as connecting exhaust fans to vents or creating temporary ventilation solutions during renovations. Their flexibility and ease of installation make them a practical choice for DIY projects.

ducting hose

Choosing the Right Ducting Hose

When selecting a ducting hose, several factors must be considered

- Material The choice of material directly impacts durability, flexibility, and temperature resistance. For instance, if the hose is to be used in high-heat environments, a heat-resistant material like silicone may be necessary.

- Diameter The diameter of the ducting hose should match the system’s requirements. A correctly sized hose ensures optimal airflow and prevents restrictions that could affect performance.

- Purpose Different applications may require specific hose designs, such as reinforced versions for high-pressure or high-velocity applications. Understanding the intended use helps in selecting the appropriate product.

Maintenance and Care

Regular maintenance is essential for ensuring the longevity and efficiency of ducting hoses. This includes periodic inspections for wear and tear, cleaning to prevent clogs, and ensuring connections remain secure. Proper care can help prevent costly replacements and maintain optimal airflow.

Conclusion

Ducting hoses are a vital component in air management across various industries and applications. Their flexibility, adaptability, and durability make them a go-to solution for moving air and materials efficiently. Whether in industrial settings, HVAC systems, agriculture, or home use, understanding the importance of ducting hoses can lead to better airflow management and improved environments. With the right choice and maintenance, ducting hoses can provide reliable performance for years to come, enhancing overall operational efficiency and safety.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025