High-Pressure Welding Hose for Optimal Performance and Durability in Industrial Applications

Understanding Double Welding Hose Features and Applications

Welding is a vital process in various industries, including construction, manufacturing, and automotive, where metal parts need to be joined together securely. One critical component that plays an essential role in the safety and efficiency of welding operations is the double welding hose. This specialized hose is designed to carry both oxygen and fuel gases, which are required for various welding techniques such as oxy-acetylene welding.

What is Double Welding Hose?

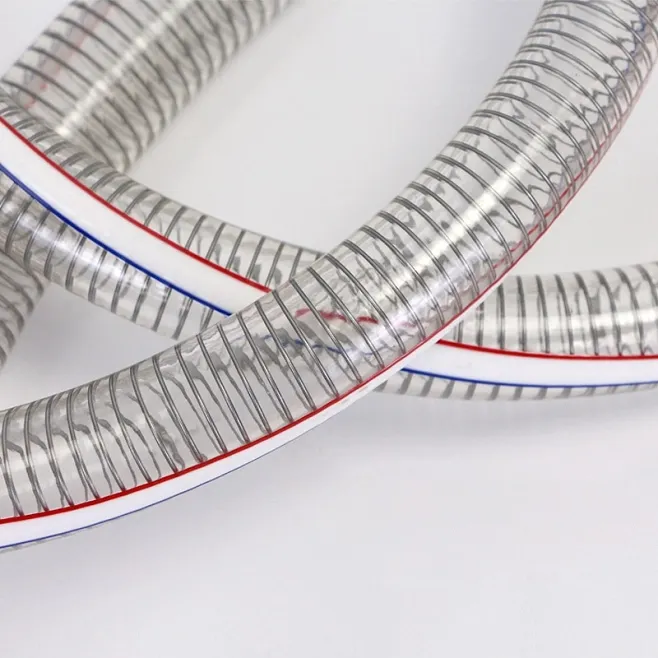

A double welding hose consists of two separate tubes within a single assembly. Typically, one tube is designated for oxygen, and the other is for fuel gas, such as acetylene or propane. This design helps ensure that the gases remain separated, which is crucial for safety. The hoses are usually color-coded to prevent any accidental misconnections; the oxygen hose is generally green, while the fuel gas hose is red.

Features of Double Welding Hose

1. Durability Double welding hoses are constructed from high-quality materials that provide excellent resistance to heat, abrasion, and certain chemicals. This durability ensures that they can withstand the rigors of welding environments without succumbing to wear and tear.

2. Flexibility Welding hoses are designed to be flexible, allowing welders to maneuver easily around their workspace. This flexibility is essential when working in confined spaces or when making intricate repairs.

3. Safety One of the most critical features of double welding hoses is their safety. With the hoses separated, there is a reduced risk of cross-contamination between the gases, which can be extremely hazardous. Additionally, many double welding hoses are equipped with safety burst protectors that prevent them from bursting under high-pressure conditions.

4. Temperature Resistance Welding procedures can generate significant heat; therefore, double welding hoses are engineered to resist high temperatures. This feature is essential to maintaining the integrity of the hoses and preventing leaks.

5. Lightweight Design The combination of lightweight materials and effective construction makes these hoses easy to handle. This is particularly important for welders who spend long hours on the job and need equipment that won’t add unnecessary fatigue.

Applications of Double Welding Hose

double welding hose

The versatility of double welding hoses makes them suitable for a variety of welding applications

1. Oxy-Acetylene Welding This is one of the most common welding processes that utilize a double welding hose. It involves mixing oxygen and acetylene in controlled proportions to produce a high-temperature flame capable of melting metals.

2. Cutting Applications Apart from welding, these hoses are also used in cutting operations. The oxy-fuel cutting process requires an oxygen and fuel mixture to create flames hot enough to cut through metal sheets and structures.

3. Heating and Brazing Welders use double welding hoses for heating applications as well, such as preheating metal surfaces before welding or during brazing processes, where a filler metal is melted to join two base metals.

4. Metal Fabrication In industries where metal parts are fabricated and assembled, double welding hoses are invaluable. Their ability to provide stable and reliable gas flows ensures the quality and strength of the welds.

Maintenance and Care

To ensure the longevity of double welding hoses, proper maintenance is crucial. Here are some tips for care

- Regular Inspection Check hoses for any signs of wear, kinks, or damage. Replace any hose that appears to be compromised. - Proper Storage Store hoses in a cool, dry place away from direct sunlight and sharp objects. Coiling hoses neatly can help prevent damage. - Avoid Overstretching Be mindful of the hose's length to avoid overstretching, which can lead to cracks and leaks. - Use Correct Connections Always use the proper fittings and adapters that are compatible with your welding equipment to avoid leaks and ensure safe operation.

Conclusion

In summary, double welding hoses are an integral part of the welding process. Their durable and flexible design, combined with safety features, makes them indispensable for any professional setup. Understanding the features and applications of these hoses can significantly enhance the efficiency and safety of welding operations. Investing in high-quality double welding hoses is vital for achieving optimal results while maintaining a safe working environment.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025