discharge hoses

Understanding Discharge Hoses Key Components in Fluid Transport

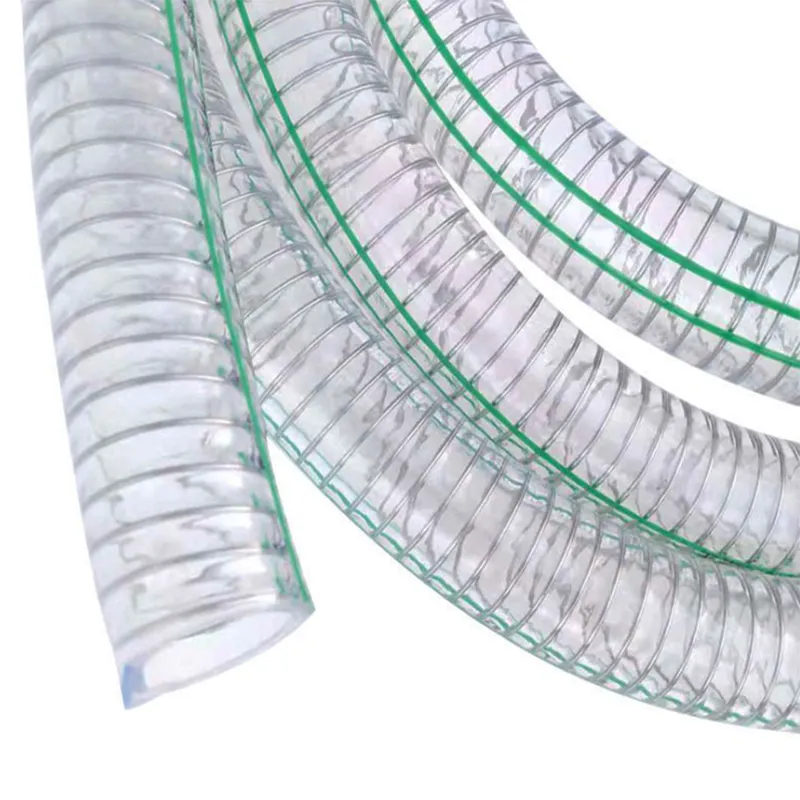

Discharge hoses play a crucial role in various industries that require the efficient and safe transport of fluids. From agriculture to construction, these flexible tubes are designed to handle different types of liquids, including water, chemicals, and even slurries. Understanding the features, applications, and maintenance of discharge hoses can significantly enhance their effectiveness and lifespan.

What Are Discharge Hoses?

Discharge hoses are flexible tubes used to move fluids from one location to another. They are typically made from durable materials such as rubber, PVC, or polyurethane, which can withstand the pressure and abrasion encountered during their operation. The hoses are often equipped with fittings or couplings at both ends to connect to pumps or other apparatuses, allowing for seamless fluid transfer.

One of the defining characteristics of discharge hoses is their ability to handle various pressures and flow rates. Depending on the application, they can be designed for low-pressure discharge systems, such as irrigation, or high-pressure environments, such as industrial pumping operations.

Applications of Discharge Hoses

The versatility of discharge hoses makes them indispensable in numerous settings. In agriculture, these hoses are used for irrigation and drainage purposes. They transport water from pumps to fields, ensuring crops receive adequate moisture. In construction, discharge hoses are vital for dewatering sites, managing runoff, and transferring concrete or other construction materials.

Additionally, the chemical industry relies on specialized discharge hoses that can transport hazardous materials safely. These hoses are constructed with materials that resist corrosion and can handle the specific chemical properties of the fluids being transported.

discharge hoses

Selecting the Right Discharge Hose

Choosing the appropriate discharge hose involves several considerations. First, it is essential to determine the type of fluid being transported. This includes understanding the fluid's temperature, viscosity, and whether it contains any abrasive particles. Based on these factors, one can select a hose that has the necessary chemical resistance and durability.

Another critical aspect is the hose diameter and length. A larger diameter allows for greater flow rates, while the length should be sufficient to reach the desired destination without causing significant pressure loss. Additionally, the hose's flexibility is an important consideration, especially in environments where bends and turns are common.

Maintenance Best Practices

To ensure the longevity and efficiency of discharge hoses, regular maintenance is necessary. This includes visual inspections for any signs of wear, such as cracks or leaks, and cleaning the hoses to prevent clogs. Proper storage is also vital; hoses should be coiled correctly and kept in a dry, cool place to avoid degradation caused by UV exposure or extreme temperatures.

Moreover, it is crucial to follow manufacturer guidelines regarding usage limits. Exceeding the recommended pressure rating or using the hose for inappropriate applications can lead to premature failure.

Conclusion

In summary, discharge hoses are essential tools in fluid transport across various industries. By understanding their construction, suitable applications, and maintenance requirements, users can maximize their performance and ensure safe and efficient fluid management. Whether for agricultural irrigation or industrial pumping, selecting the right discharge hose is vital to operational success.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025