braided hose vs standard hose

Braided Hose vs. Standard Hose An In-depth Comparison

When it comes to selecting the right type of hose for various applications, the choice often boils down to two primary options braided hoses and standard hoses. Each type has its own set of characteristics, advantages, and disadvantages. Understanding the fundamental differences between braided hoses and standard hoses can help consumers make informed decisions based on their specific needs.

What is a Braided Hose?

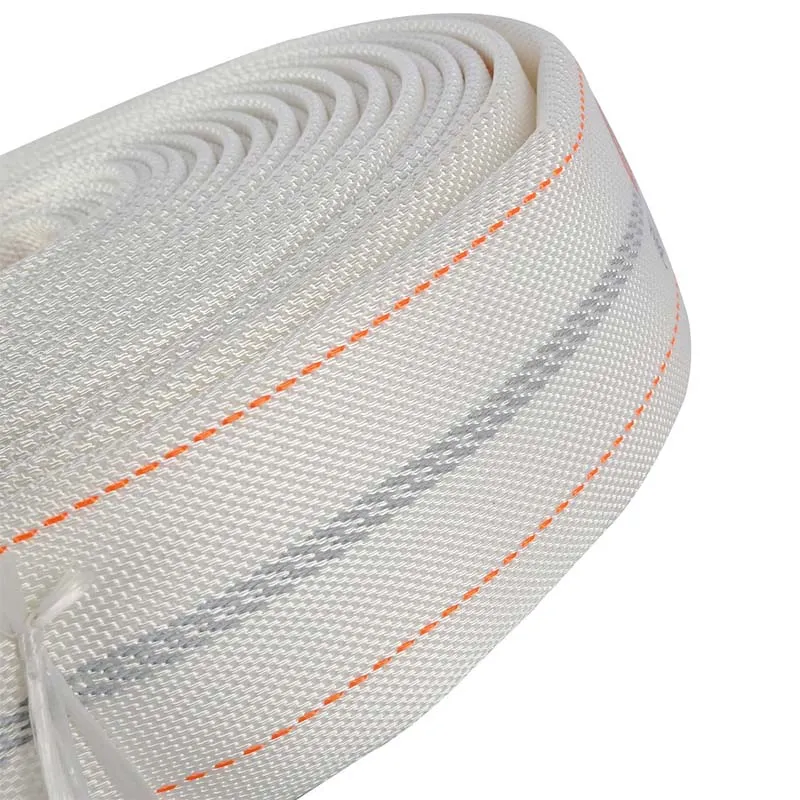

A braided hose is constructed from multiple layers of material, typically consisting of an inner tube that carries the fluid and external braided reinforcement. The braided layer is usually made from strong, flexible materials such as stainless steel or synthetic fibers, which provide added strength and pressure resistance. This design enables braided hoses to withstand high pressures and have a longer lifespan compared to standard hoses. Furthermore, the braided exterior provides additional durability against abrasion and environmental factors.

Braided hoses are commonly used in a variety of applications, including automotive, industrial, and hydraulic systems. They are particularly favored in high-pressure environments, where the risk of hose failure is high. Their flexibility also allows easy routing in tight spaces, making them suitable for complex installations.

What is a Standard Hose?

Standard hoses, on the other hand, are typically made from a single layer of rubber, plastic, or PVC, depending on the intended use. These hoses are easier to handle and are generally more affordable than braided hoses. Standard hoses are suitable for a wide range of applications, from gardening and landscaping to basic plumbing tasks. However, the limitations of standard hoses become apparent when it comes to high-pressure applications or situations where the hose may be exposed to harsh environmental conditions.

braided hose vs standard hose

While standard hoses can perform well in low-pressure situations and are ideal for domestic use, they may not be suitable for heavy-duty tasks. Over time, standard hoses can become brittle and susceptible to cuts and bursts, especially if they are not properly maintained.

Comparative Advantages

One major advantage of braided hoses is their superior pressure tolerance. They are designed to handle higher levels of pressure, typically ranging from 1500 psi to over 3000 psi, depending on the size and construction. This makes them ideal for automotive fuel lines, hydraulic systems, and other applications where safety and performance are paramount. The braided design also allows for greater flexibility and resistance to wear, meaning they can endure complex routing without compromising their structural integrity.

In contrast, standard hoses are generally lighter and more flexible than braided hoses, making them easier to maneuver in simple applications. Their lower cost also makes them an attractive option for homeowners looking for a budget-friendly solution for non-industrial tasks.

Conclusion

Ultimately, the choice between braided hoses and standard hoses will largely depend on the application's specific requirements. For those requiring high pressure and durability, braided hoses are the clear choice, offering superior performance and longevity. In contrast, standard hoses serve as a practical option for lighter tasks that do not involve high pressure or extreme conditions.

When selecting a hose, it is crucial to consider factors such as pressure ratings, material composition, and the intended application. Investing in the right type of hose can not only enhance performance but also ensure safety and reliability in usage. Whether one opts for a braided or standard hose, understanding their differences will help in making a well-informed decision tailored to individual needs.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025