braided hose vs standard hose

Braided Hose vs. Standard Hose A Comprehensive Comparison

When it comes to choosing the right tubing for various applications, two common types are often considered braided hoses and standard hoses. Each serves unique purposes, and understanding their differences can significantly affect performance, durability, and safety. This article aims to provide an in-depth comparison of these two types of hoses, highlighting their features, advantages, and potential drawbacks.

1. Construction and Design

The primary distinction lies in their construction. Standard hoses are generally made from rubber or PVC materials and consist of a single-layer design. In contrast, braided hoses have a more complex structure, combining an inner layer made from rubber or thermoplastic with an outer layer of tightly woven braided fibers—usually made from stainless steel or other robust materials. This design not only enhances the hoses' strength and durability but also allows them to withstand higher pressures and temperatures.

In applications where pressure and temperature are critical, braided hoses excel. The added layer of reinforcement provided by the braided exterior means they can handle higher pressure levels, making them suitable for automotive applications, hydraulic systems, and high-performance machinery. Conversely, standard hoses, while adequate for less demanding situations, may burst or degrade under extreme conditions. Their simpler construction makes them less resistant to abrasion and UV deterioration, which can limit their lifespan.

3. Flexibility and Weight

When it comes to flexibility, standard hoses have the upper hand, primarily due to their lighter and more supple materials. They are easy to handle, bend, and maneuver, making them ideal for simpler tasks or applications where tight spaces require flexible hoses. However, the increased stiffness of braided hoses can make them more challenging to work with. While they are generally more robust and can withstand harsh environments, this durability often comes at the cost of weight and flexibility.

4. Cost Considerations

braided hose vs standard hose

From a financial standpoint, standard hoses typically come at a lower price point compared to braided hoses. Their simpler design and common materials make them a budget-friendly option for many everyday applications. However, investing more in braided hoses may be worthwhile in scenarios where enhanced performance, safety, and longevity are essential. The initial higher cost can translate to lower maintenance and replacement expenses over time, especially in demanding environments.

5. Applications

The choice between braided and standard hoses largely depends on the intended application. Standard hoses are perfect for gardening, water transfer, and general-purpose tasks where high pressure and temperature are not significant concerns. They serve well in domestic and non-industrial settings.

On the other hand, braided hoses are favored in industries requiring heavy-duty applications. They are commonly used in automotive, aviation, marine, and hydraulic systems due to their ability to resist high pressures and temperatures. Their robustness makes them suitable for situations where failure could lead to severe consequences, preserving both worker safety and equipment integrity.

6. Performance in Extreme Conditions

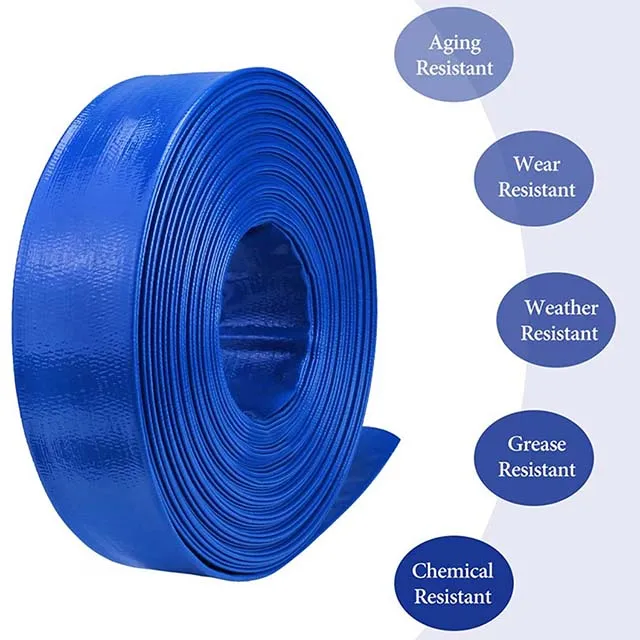

For applications involving extreme temperatures—whether hot or cold—braided hoses are preferable. They are less likely to degrade or lose integrity over time compared to standard hoses, which can become brittle or soft under extreme conditions. Additionally, braided hoses often feature better resistance to chemicals and oils, making them suitable for use in environments where exposure to various substances is a concern.

Conclusion

In conclusion, the choice between braided hoses and standard hoses depends largely on the specific needs of the application. For high-pressure and high-temperature environments, braided hoses are the clear winner due to their strength, durability, and resistance to various external factors. However, for more straightforward tasks that require flexibility and are cost-sensitive, standard hoses may be sufficient.

Ultimately, understanding the differences between these two types of hoses will help you make an informed decision tailored to your specific requirements. Consider factors such as the environment, pressure levels, temperature conditions, and budget to determine the best option for your needs.

-

Welded Wire Mesh Panel: Durable, Versatile, and AffordableNewsJul.28,2025

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025