braided hose vs standard hose

Braided Hose vs. Standard Hose An In-Depth Comparison

Hoses are essential components in various applications across industries, from automotive to industrial machinery. Two popular types of hoses are braided hoses and standard hoses. While both serve similar functions, they vary significantly in construction, performance, and specific use cases. This article explores these differences to help you make an informed decision when selecting the right hose for your needs.

Construction and Design

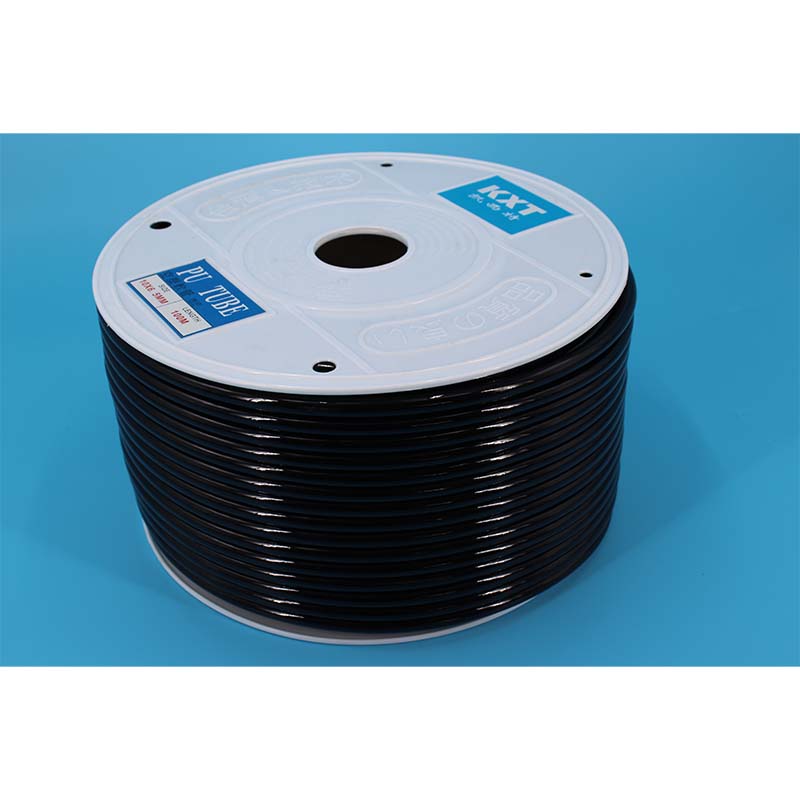

The most noticeable difference between braided hoses and standard hoses lies in their construction. Standard hoses are typically made from a single layer of rubber or plastic, providing adequate flexibility and resistance to common wear and tear. They are straightforward in design and largely effective for basic applications, such as garden watering, low-pressure air, or fluid transfer.

In contrast, braided hoses are constructed with an additional layer of reinforcement. This layer consists of woven materials, often stainless steel or synthetic fibers, which surround the inner tube. This braiding not only enhances the strength of the hose but also allows it to withstand higher pressures and temperatures. The outer layer serves as a protective barrier, providing durability against abrasions, cuts, and environmental factors. As a result, braided hoses are widely used in high-performance applications where safety and reliability are critical.

Performance and Durability

When it comes to performance, braided hoses generally outperform standard hoses. The added reinforcement in braided hoses means they can handle significantly higher pressure ratings, making them suitable for hydraulic systems and specialized machinery. Their construction also allows them to maintain their shape under extreme stress, reducing the risk of kinking and collapsing, which can be a common issue with standard hoses.

braided hose vs standard hose

Standard hoses, while functional for lower pressure applications, can be prone to damage under strenuous conditions. They may kink, swell, or even burst if they are subjected to pressures beyond their limits. This can lead to costly downtime and repairs, especially in industrial settings where efficiency is paramount.

Moreover, braided hoses often have improved flexibility and resistance to temperature variations. This makes them suitable for both indoor and outdoor use, where temperature fluctuations could otherwise affect the performance of a standard hose. Consequently, braided hoses can last significantly longer than their standard counterparts, providing an excellent return on investment.

Applications

The choice between braided hoses and standard hoses often comes down to their intended use. Standard hoses are typically sufficient for lighter tasks, such as home gardening, light-duty automotive applications, and general fluid transfer. They are more affordable and easier to handle, making them a popular choice for casual users.

However, for more demanding tasks, braided hoses shine. They are commonly used in high-performance automotive applications, hydraulic systems, aviation, and industrial machinery. Their ability to handle high pressure and temperature makes them ideal for tasks that could otherwise cause standard hoses to fail. Additionally, braided hoses are often preferred in industries that prioritize safety and reliability, such as manufacturing and petrochemicals.

Conclusion

In conclusion, choosing between braided hoses and standard hoses hinges on understanding your specific requirements. While standard hoses are adequate for light-duty tasks, braided hoses offer superior durability, pressure resistance, and longevity. If your application demands high performance and reliability, investing in a braided hose is the way to go. On the other hand, for everyday tasks that don’t require high pressure or extreme conditions, a standard hose could be a more economical and practical solution. Ultimately, understanding the strengths and weaknesses of each type can help you make the best choice for your needs.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025