Jan . 28, 2025 01:35

Back to list

air hose rubber vs pvc

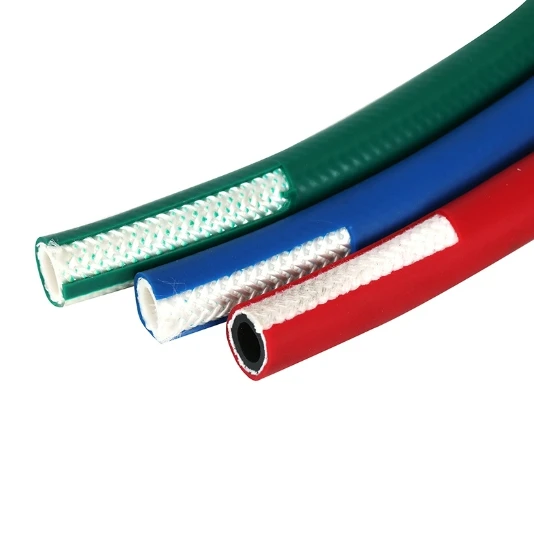

Air hoses are fundamental tools in various industries and DIY projects, serving to transfer compressed air efficiently. The two prevalent materials used in manufacturing air hoses are rubber and PVC, each presenting distinct advantages and characteristics. Making an informed decision requires understanding their properties, applications, and how they impact performance and durability.

However, PVC hoses do have limitations, particularly in extreme temperatures. They tend to become brittle in cold weather, increasing the risk of cracks or splits under pressure. In high temperatures, PVC can deform, potentially leading to compromised performance. Therefore, PVC hoses are typically more suited for indoor or controlled environments where temperature fluctuations are minimal. When assessing air hose options for specific requirements, considering the operational environment is critical. For industrial settings or outdoor applications, rubber hoses provide the reliability and durability needed to perform under harsh conditions. In contrast, for light-duty tasks or indoor applications, PVC hoses offer a cost-effective and user-friendly solution. In terms of authority and trustworthiness, it's essential to consider the certifications and industry standards that each type of hose meets. Rubber hoses often meet higher industrial standards due to their robust nature and ability to withstand various environmental factors. When compliance with specific safety regulations is paramount, rubber hoses are frequently preferred. For individuals or businesses prioritizing environmental considerations, examining the production process and recyclability of each material can guide decision-making. Rubber is often derived from natural or synthetic sources with varying environmental impacts, while PVC production can involve more environmentally sensitive processes. Choosing brands that prioritize sustainability and eco-friendly manufacturing practices can enhance trust and responsibility within this context. Ultimately, the decision between rubber and PVC air hoses rests on a balance of priorities—whether it be flexibility and durability, or cost-effectiveness and ease of handling. By evaluating the specific demands of the application and weighing the benefits and limitations of each material, users can select the optimal hose to enhance performance while ensuring safety and reliability.

However, PVC hoses do have limitations, particularly in extreme temperatures. They tend to become brittle in cold weather, increasing the risk of cracks or splits under pressure. In high temperatures, PVC can deform, potentially leading to compromised performance. Therefore, PVC hoses are typically more suited for indoor or controlled environments where temperature fluctuations are minimal. When assessing air hose options for specific requirements, considering the operational environment is critical. For industrial settings or outdoor applications, rubber hoses provide the reliability and durability needed to perform under harsh conditions. In contrast, for light-duty tasks or indoor applications, PVC hoses offer a cost-effective and user-friendly solution. In terms of authority and trustworthiness, it's essential to consider the certifications and industry standards that each type of hose meets. Rubber hoses often meet higher industrial standards due to their robust nature and ability to withstand various environmental factors. When compliance with specific safety regulations is paramount, rubber hoses are frequently preferred. For individuals or businesses prioritizing environmental considerations, examining the production process and recyclability of each material can guide decision-making. Rubber is often derived from natural or synthetic sources with varying environmental impacts, while PVC production can involve more environmentally sensitive processes. Choosing brands that prioritize sustainability and eco-friendly manufacturing practices can enhance trust and responsibility within this context. Ultimately, the decision between rubber and PVC air hoses rests on a balance of priorities—whether it be flexibility and durability, or cost-effectiveness and ease of handling. By evaluating the specific demands of the application and weighing the benefits and limitations of each material, users can select the optimal hose to enhance performance while ensuring safety and reliability.

Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE