Top PVC Hose Manufacturers Delivering Quality and Durability to Your Projects

Understanding PVC Hose Manufacturers A Comprehensive Overview

Polyvinyl chloride (PVC) hoses have become an indispensable component across various industries due to their versatility, durability, and affordability. As a leading material in the hose manufacturing sector, PVC provides an excellent balance of performance and cost-effectiveness. This article explores the role of PVC hose manufacturers, delves into the production processes, applications, and advancements in PVC hose technology.

The Role of PVC Hose Manufacturers

PVC hose manufacturers are pivotal in the production of hoses used in many sectors, including agriculture, construction, plumbing, automotive, and industrial processes. These manufacturers create hoses that cater to specific needs, such as water delivery, chemical transportation, and air transfer. They focus on developing high-quality products that meet rigorous industry standards, ensuring safety, reliability, and efficiency.

The production of PVC hoses involves several stages, including design, material selection, extrusion, and finishing. Manufacturers typically employ skilled engineers and technicians who are well-versed in the characteristics of PVC and the nuances of hose design. Their expertise enables them to produce hoses tailored to customer specifications, which can include varying diameters, lengths, colors, and reinforcement options.

The Production Process

The manufacturing process of PVC hoses begins with the selection of raw materials. Ethylene and chlorine, the principal components of PVC, are sourced and processed. Manufacturers then combine these materials with various additives to enhance performance properties, such as flexibility, UV resistance, and chemical compatibility.

The next stage involves the extrusion process, where the mixed PVC material is heated and forced through a die to create the desired shape. During this phase, hoses may include reinforcements like polyester or nylon, which improve strength and prevent kinking. Once formed, the hoses are cooled, cut to size, and may undergo additional processes such as surface treatment or the addition of fittings.

Quality control is a crucial step in the production of PVC hoses. Manufacturers conduct rigorous testing to ensure that their products meet industry standards for pressure resistance, durability, and chemical resistance. This is essential for maintaining customer trust and ensuring the safety of the end-users.

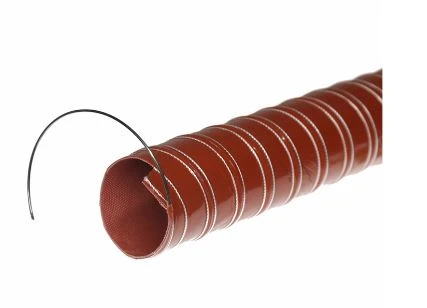

pvc hose manufacturer

Applications of PVC Hoses

The versatility of PVC hoses allows them to be used in a wide range of applications. In agriculture, for instance, these hoses are used for irrigation systems, delivering water efficiently across vast fields. In construction, PVC hoses facilitate the transfer of water and other fluids for various purposes, while in plumbing, they are often used to create flexible connections in residential and commercial systems.

In the automotive industry, PVC hoses serve a critical role in cooling systems, fuel lines, and air intake systems because of their resistance to oils, chemicals, and extreme temperatures. Additionally, PVC hoses are extensively used in industrial settings for conveying various materials, from slurries to gasses, demonstrating their adaptability and reliability.

Advancements in Technology

Recent advancements in manufacturing technology have allowed PVC hose manufacturers to improve product performance and expand their offerings. The integration of digital technologies, such as automation and data analytics, has streamlined production processes, increasing efficiency and reducing waste.

Moreover, innovative materials science has led to the development of advanced PVC formulations that enhance the properties of hoses. Manufacturers are now able to produce lightweight, yet robust hoses that maintain flexibility in extreme temperatures and harsh conditions. These innovations contribute to sustainability efforts by ensuring longer product lifespans and reducing the frequency of replacements.

Conclusion

In conclusion, PVC hose manufacturers play a crucial role in various industries by producing versatile, reliable, and cost-effective hoses. Through meticulous design and production processes, they cater to a diverse range of applications, meeting the needs of different sectors. As technology continues to advance, the future appears bright for PVC hose manufacturing, with innovations that will enhance performance, sustainability, and adaptability. By investing in research and development, manufacturers can ensure that they remain competitive in an evolving market, ultimately benefiting businesses and consumers alike.

-

Unrivaled Performance and Applications of PU Pneumatic Hoses and TubesNewsJun.11,2025

-

The Transparent World of Industrial Tubing and Hosing SolutionsNewsJun.11,2025

-

The Intricate World of Pneumatic Conduits: Tubes and HosesNewsJun.11,2025

-

The Dynamic Landscape of Pneumatic Conduits: Unraveling Key ComponentsNewsJun.11,2025

-

The Diverse Applications and Significance of Transparent PVC TubingNewsJun.11,2025

-

High - Pressure Pneumatic Tubing and Systems: An In - Depth LookNewsJun.11,2025