Comparing Braided Hoses and Standard Hoses for Optimal Performance and Durability

Braided Hose vs. Standard Hose Understanding the Differences

When it comes to choosing the right hose for a specific application, understanding the type of hose that best meets your needs is essential. Two of the most common options available in the market are braided hoses and standard hoses. Each type comes with its own set of advantages and disadvantages, making them suitable for different applications. In this article, we will explore the differences between braided hoses and standard hoses to help you make an informed decision.

Construction and Design

The primary difference between braided hoses and standard hoses lies in their construction. Standard hoses are typically made from a single layer of material, such as rubber or PVC. This makes them lightweight, flexible, and easy to handle for general applications. However, their single-layer construction limits their ability to withstand high pressures and temperatures.

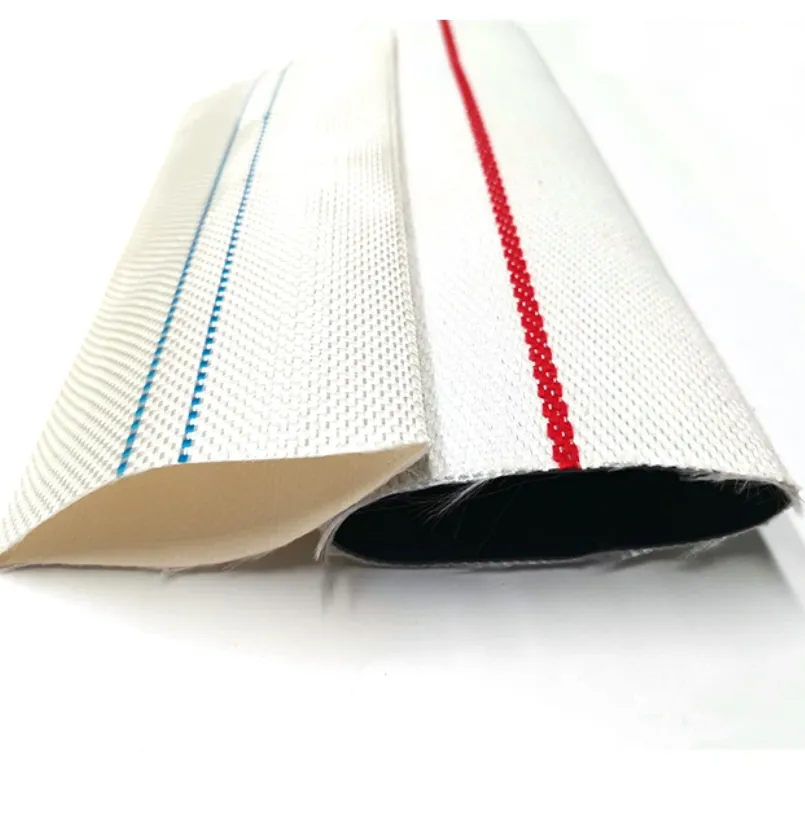

On the other hand, braided hoses are constructed using multiple layers, usually combining a robust inner layer made from rubber or thermoplastic with an outer layer of braided material, often nylon or stainless steel. This braided design provides enhanced strength and durability, allowing braided hoses to handle higher pressures and harsher conditions. The braided exterior also offers increased resistance to abrasion, making them suitable for environments where wear and tear is a concern.

Performance and Flexibility

When it comes to performance, braided hoses have the upper hand. Their ability to withstand high pressure makes them ideal for hydraulic applications and in situations where consistent, high-performance delivery of fluids is required. They also maintain their shape under pressure, reducing the risk of kinking or collapsing that can occur with standard hoses, especially in high-stress situations.

braided hose vs standard hose

Standard hoses, while still effective for many applications, may struggle under high pressure or harsh conditions. They can kink or collapse, which can lead to disruptions in fluid flow and potential damage to the hose itself. However, their flexibility makes them easier to handle and maneuver in tight spaces, which can be a valuable asset in certain situations.

Applications

The applications of braided hoses and standard hoses vary significantly due to their inherent characteristics. Braided hoses are widely used in industries such as automotive, aerospace, and manufacturing, where reliability and performance are paramount. They are suitable for high-pressure systems, fuel lines, and even as hydraulic lines in machinery.

Conversely, standard hoses are more commonly used in household and light industrial applications. They are perfect for tasks like watering gardens, washing cars, or transporting water and air in various settings. Their affordability and ease of use make them a favored choice for consumers who require a hose for everyday tasks without the need for extreme durability or pressure resistance.

Conclusion

In summary, both braided hoses and standard hoses have their own unique advantages tailored to specific uses. If your application demands high pressure, durability, and resistance to wear and tear, a braided hose might be the best choice. On the other hand, for general purposes or lighter-duty tasks, a standard hose could prove adequate and more cost-effective.

Ultimately, the decision between braided and standard hoses should be based on individual needs, including the type of fluid being transported, the pressure requirements, and the environment in which the hose will be used. By understanding the differences between these two types of hoses, you can select the most appropriate option for your specific application, ensuring efficiency and longevity in your projects.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025