Comparing Braided Hoses and Standard Hoses for Better Performance and Durability

Braided Hose vs. Standard Hose Which Is Right for Your Needs?

When it comes to choosing hoses for various applications, it's essential to understand the differences between braided hoses and standard hoses. Each type has its own set of advantages and disadvantages, making them suited for different tasks. In this article, we'll delve into the characteristics, benefits, and potential drawbacks of both braided hoses and standard hoses to help you make an informed decision.

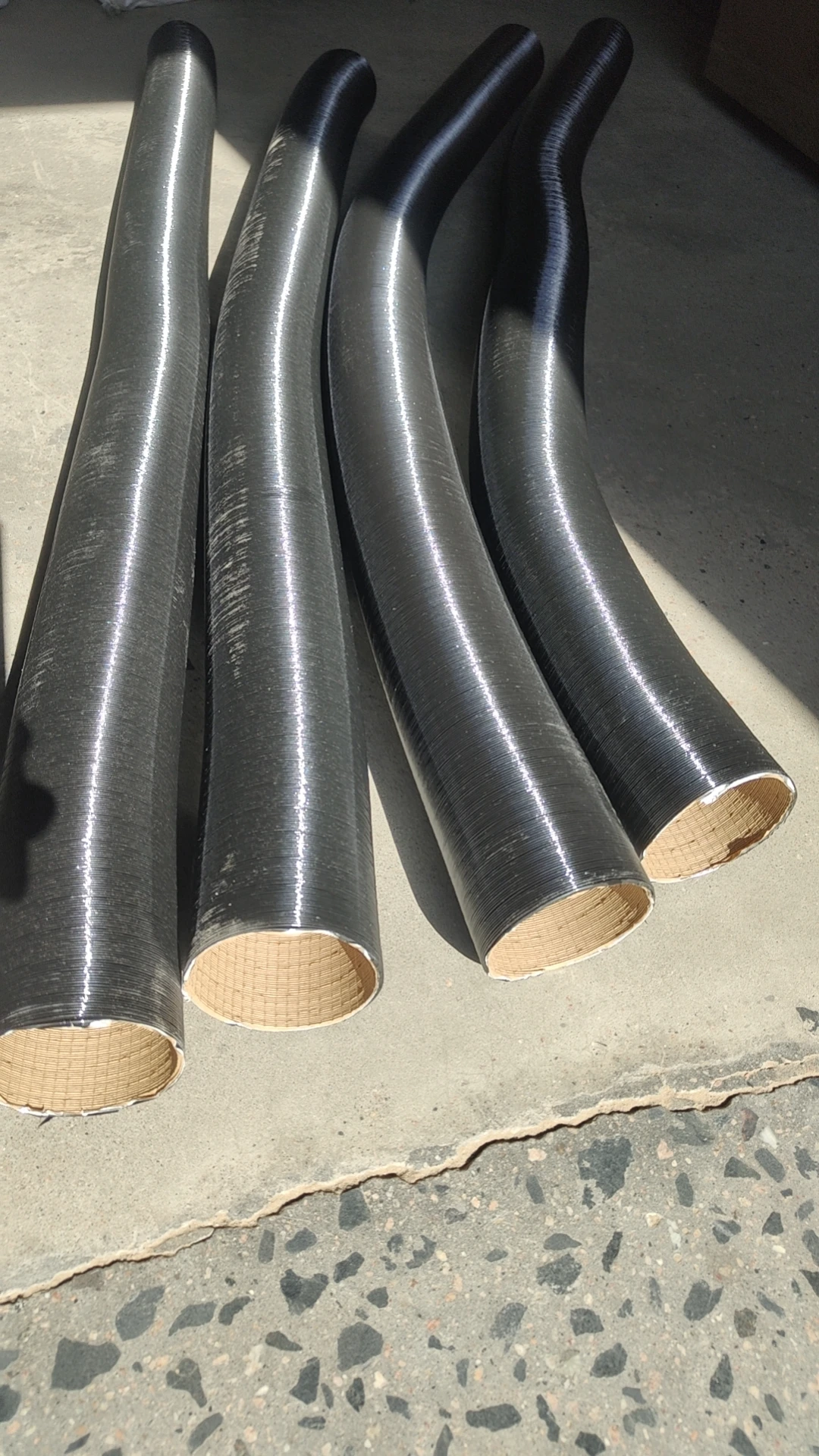

Understanding Braided Hoses

Braided hoses are made from a rubber or thermoplastic core that is reinforced with a woven mesh of composite materials, often steel or other robust fibers. This braided layer adds considerable strength and durability to the hose, making it highly resistant to wear and punctures. Braided hoses are renowned for their flexibility while maintaining high pressure resistance.

One of the most significant advantages of braided hoses is their ability to withstand extreme temperatures and pressures, making them ideal for high-performance applications. They are commonly used in automotive, hydraulic, and industrial sectors, where durability and flexibility are paramount. The braided design also protects the hose from external abrasion, ensuring a longer lifespan.

Exploring Standard Hoses

Standard hoses, on the other hand, are typically made from a single type of material, such as rubber or PVC, without the added reinforcement of a braided layer. While they can come in various diameters and lengths, standard hoses often lack the rigorous durability of their braided counterparts. They are generally more cost-effective and are suitable for applications with lower pressure and temperature requirements.

Standard hoses are commonly used for garden watering, air service, and low-pressure applications. They are lightweight and easy to handle, which appeals to casual users who need a functional hose without special features.

Comparative Benefits

braided hose vs standard hose

When comparing braided hoses to standard hoses, one can identify clear benefits to both options. Braided hoses excel in high-pressure situations, providing safety and reliability where traditional hoses may fail. Their construction allows them to handle sharp bends and tight spaces without kinking, a common problem in standard hoses.

On the other hand, standard hoses are often more affordable and easier to procure for everyday tasks where high durability is not essential. They are sufficient for simple applications like watering plants or washing a car, where pressure requirements are minimal.

Drawbacks to Consider

Despite their numerous advantages, braided hoses come with a higher price tag due to the complexity of their design and materials. They may also be heavier and less flexible than standard hoses, which can make them cumbersome in certain scenarios. Additionally, installation of braided hoses may require specialized knowledge or tools, depending on the application.

Standard hoses, while less expensive and easier to use, can wear out more quickly. They may burst under high pressure or become brittle over time, leading to leaks that may require replacement. Users may need to factor in the lifespan and reliability when choosing to go with a standard hose.

Conclusion

Ultimately, the choice between braided hoses and standard hoses depends on the specific needs of the application. For high-pressure or high-temperature environments where durability is non-negotiable, braided hoses are the clear winner. However, for regular gardening or low-pressure tasks, standard hoses provide a budget-friendly and adequate solution.

Evaluate your requirements carefully consider the pressure, temperature, environment, and budget. With the right information, you can choose the hose that best suits your needs, ensuring optimal performance for your tasks.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025