reinforced vacuum tubing

Reinforced Vacuum Tubing An Essential Component for Modern Applications

In the realm of industrial processing and fluid transfer, the efficiency and reliability of equipment are paramount. One component that has garnered significant attention in recent years is reinforced vacuum tubing. This specialized type of tubing plays a crucial role in a variety of applications, providing durable, efficient solutions for transporting gases and liquids in environments where vacuum conditions are necessary.

What is Reinforced Vacuum Tubing?

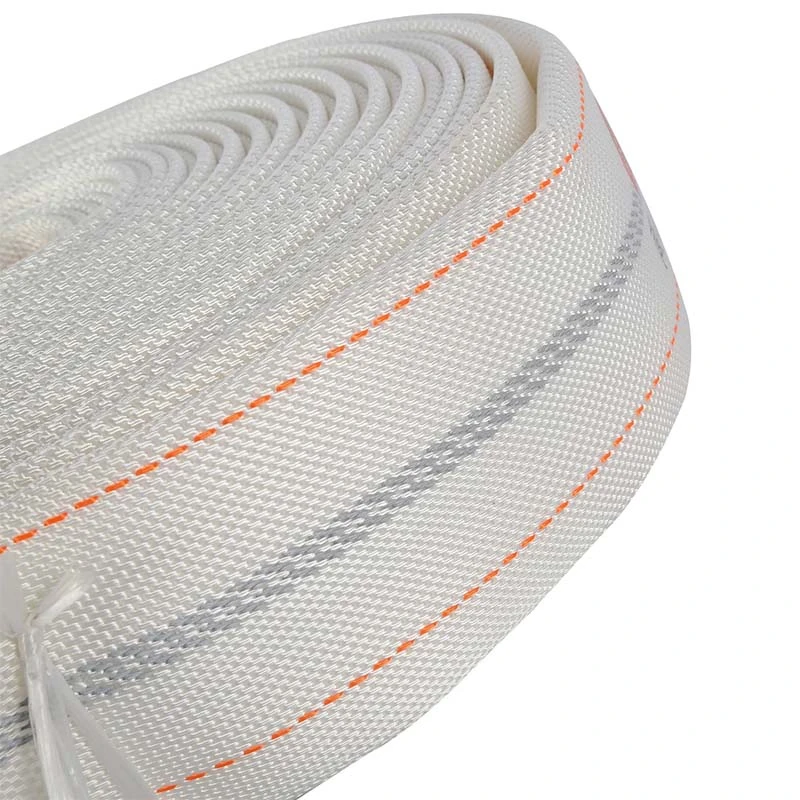

Reinforced vacuum tubing is designed to withstand negative pressure situations while maintaining structural integrity. It is typically composed of several layers, with the outer layer providing protection against abrasion and environmental factors, while the inner layer ensures optimal fluid flow. The reinforcement can be made from materials such as braided nylon or polyester, which add strength and flexibility without compromising the tubing’s ability to maintain a vacuum.

Applications

The applications of reinforced vacuum tubing are vast and varied. One of the most prominent industries utilizing this type of tubing is the medical sector. In hospitals and laboratories, vacuum tubing is employed for the safe transport of samples and hazardous materials. This is critical in ensuring the integrity of samples during testing and analysis, as well as in the safe disposal of waste products.

Additionally, reinforced vacuum tubing is essential in industrial sectors such as food processing, chemical manufacturing, and pharmaceuticals. In food processing, for instance, vacuum systems rely on strong tubing to create a controlled environment that helps preserve food quality. In chemical plants, the tubing’s ability to resist corrosive substances makes it indispensable for transferring reactive materials without leakage or contamination.

Advantages of Reinforced Vacuum Tubing

reinforced vacuum tubing

The benefits of using reinforced vacuum tubing are numerous. First and foremost, its durability is a significant advantage. The reinforced structure allows it to withstand high levels of stress, making it suitable for high-demand environments. Furthermore, its flexibility means it can be installed in tight spaces or adapted to complex systems without kinking, which could otherwise lead to system failures.

Another advantage is the tubing's resistance to temperature fluctuations. Many reinforced vacuum tubings are designed to operate effectively across a range of temperatures, which is essential in processes that involve both heating and cooling phases. This thermal stability ensures that the tubing does not degrade or deform, thus maintaining a consistent and reliable performance.

Installation and Maintenance

Proper installation of reinforced vacuum tubing is critical to ensure optimal performance. It is essential to select the right diameter and material based on the application and the specific requirements of the system. Users should also pay attention to the bending radius to prevent kinks that could impede flow.

Maintenance involves regular inspections to check for wear and tear, especially in environments where the tubing is exposed to harsh chemicals or physical abrasion. It is advisable to replace any damaged sections promptly to avoid compromising the entire system.

Conclusion

In summary, reinforced vacuum tubing is an integral part of many industries, providing reliable solutions for the transport of fluids and gases under vacuum conditions. Its robust design, combined with versatility and resistance to various environmental factors, makes it an ideal choice for applications ranging from medical facilities to industrial processing. As technology continues to advance, the importance of such specialized components will only grow, underscoring the need for innovation in materials and design to meet the evolving demands of modern applications.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025