oxy acetylene hose sizes

Understanding Oxy-Acetylene Hose Sizes A Guide for Welders

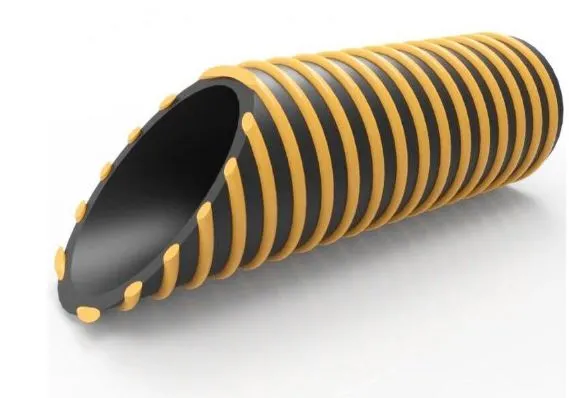

Oxy-acetylene welding is a versatile and widely used method for cutting and welding metals. Central to this process is the oxy-acetylene torch, which requires specific hoses to safely transport the gases needed for combustion. Understanding the sizes and specifications of oxy-acetylene hoses is crucial for ensuring safety and efficiency in welding projects.

Understanding Oxy-Acetylene Hose Sizes A Guide for Welders

The inner diameter of oxy-acetylene hoses is an important specification. Most commonly used diameters are 1/4 inch, 3/8 inch, and 1/2 inch. The size of the hose affects the volume of gas delivered to the torch. For instance, smaller diameters may be suitable for light welding or precise work, while larger diameters are better for heavy-duty tasks that require a higher gas flow. When working on large projects or using a larger torch tip, opting for a 3/8 inch or 1/2 inch hose can ensure a steady supply of gas without pressure drops.

oxy acetylene hose sizes

Length is another critical consideration. Hoses can range from 10 to 100 feet or more. While longer hoses provide flexibility in movement, they can also lead to pressure loss over distance. Thus, if long distances are required, using a larger diameter hose can help mitigate this issue. It's essential to strike a balance to ensure that you have adequate maneuverability without compromising gas flow.

When purchasing oxy-acetylene hoses, one should also pay attention to the material and construction. Hoses should be made from high-quality rubber or synthetic compounds resistant to abrasions, cuts, and high-pressure conditions. Ensure that the hoses are rated for both propane and acetylene if you're planning to use them interchangeably. Safety features, such as flame-resistant properties and built-in check valves, are also crucial for protecting against backfires and gas leaks.

Finally, regular inspection and maintenance of hoses are vital. Check for any signs of wear, such as cracks or bulges, which could compromise safety. Always store hoses in a coiled position and away from direct sunlight or extreme temperatures, as these conditions can deteriorate the material over time.

In conclusion, understanding the sizes and specifications of oxy-acetylene hoses is fundamental for any welder. By selecting the appropriate diameter and length, and ensuring the highest quality materials, you can improve safety and efficiency in your welding tasks. Whether you are a hobbyist or a professional, the right hoses will enhance your capabilities and ensure a successful welding experience.

-

Unrivaled Performance and Applications of PU Pneumatic Hoses and TubesNewsJun.11,2025

-

The Transparent World of Industrial Tubing and Hosing SolutionsNewsJun.11,2025

-

The Intricate World of Pneumatic Conduits: Tubes and HosesNewsJun.11,2025

-

The Dynamic Landscape of Pneumatic Conduits: Unraveling Key ComponentsNewsJun.11,2025

-

The Diverse Applications and Significance of Transparent PVC TubingNewsJun.11,2025

-

High - Pressure Pneumatic Tubing and Systems: An In - Depth LookNewsJun.11,2025