Explore the Versatility and Benefits of Oxy Acetylene Hoses

When it comes to welding and cutting applications, oxy acetylene hoses are indispensable. These hoses are specifically designed to transport oxygen and acetylene gases safely and efficiently, making them a critical component in various welding operations. Whether you're a professional welder or a hobbyist, understanding the benefits and applications of oxy acetylene hoses can help you make the right choice for your needs.

Advantages of Oxy Acetylene Hoses

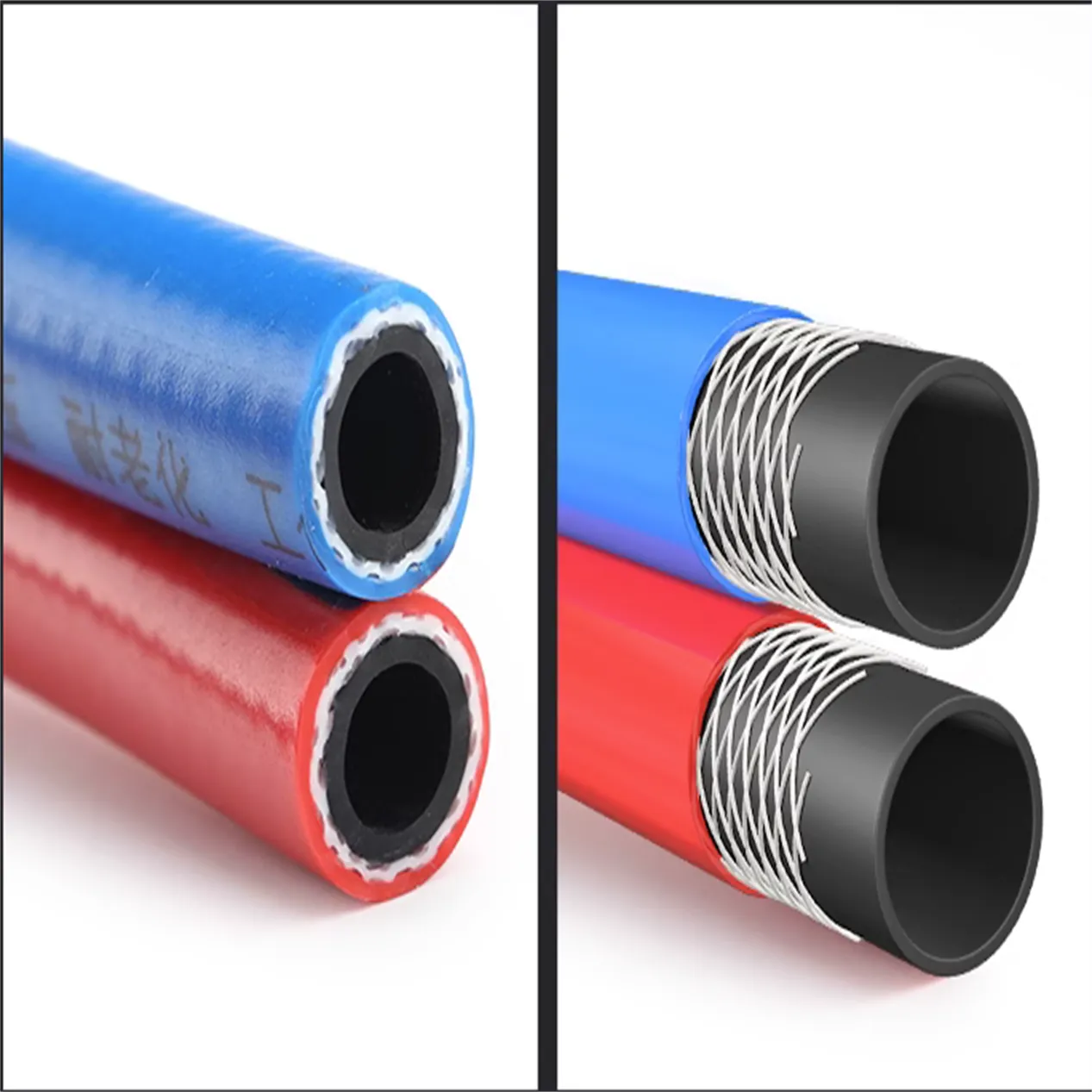

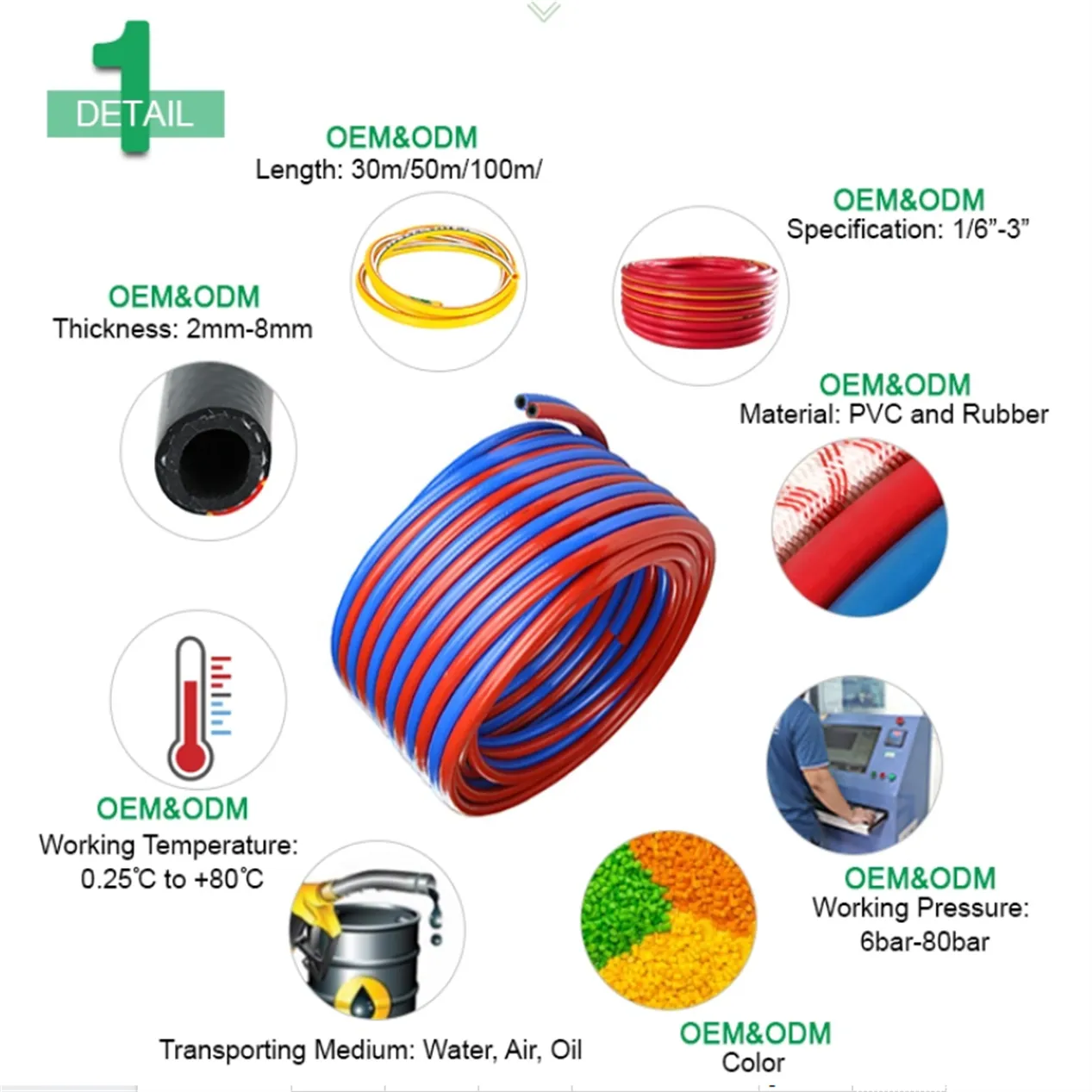

Oxy acetylene hoses offer several advantages that make them the preferred choice for many welding and cutting professionals. One of the main benefits is their durability. Made from high-quality materials such as reinforced rubber or PVC, these hoses are built to withstand the harsh conditions typically encountered in welding environments. This includes exposure to high temperatures, abrasion, and chemicals, ensuring a long lifespan and reduced need for replacements.

Another significant advantage of oxy acetylene hoses is their flexibility. These hoses are designed to be highly flexible, allowing welders to maneuver easily around the workspace. This flexibility reduces strain on the hoses, preventing kinks or bends that could disrupt the gas flow. The result is a smooth and continuous gas supply, which is crucial for maintaining consistent weld quality.

Oxy acetylene hoses are also designed with safety in mind. They come with distinct color coding – typically red for acetylene and green for oxygen – to prevent any mix-ups and ensure safe operation. The hoses are also manufactured to meet stringent safety standards, providing peace of mind when handling volatile gases like oxygen and acetylene.

Different Types of Oxy Acetylene Hoses

There are several types of oxy acetylene hoses available to suit different needs and applications. The most common type is the PVC twin welding hose, which consists of two hoses bonded together. This design ensures that the oxygen and acetylene hoses stay together, reducing the risk of tangling and making the setup more organized. The PVC twin welding hose is also lightweight and flexible, making it easy to handle in various welding and cutting operations.

For those looking for specific options, there are oxy acetylene hoses for sale in different lengths and diameters to accommodate various welding setups. Whether you need a hose for a small workshop or a large industrial facility, there are options available to meet your requirements.

The Difference Between Oxy Acetylene Hoses and Other Hoses

When comparing oxy acetylene hoses to other types of hoses, the most significant difference lies in their construction and intended use. Unlike standard air or water hoses, oxy acetylene hoses are designed specifically for transporting oxygen and acetylene gases. This means they are constructed with materials that can withstand the unique challenges posed by these gases, including high pressures and the potential for chemical reactions.

For example, a PVC twin welding hose is designed to handle the pressures of oxygen and acetylene safely, while also being resistant to the chemicals that may be present in a welding environment. In contrast, using a standard garden hose or air hose for welding could result in dangerous leaks or ruptures due to inadequate construction.

Applications of Oxy Acetylene Hoses

Oxy acetylene hoses are used in a wide range of applications, from small DIY projects to large-scale industrial welding and cutting operations. In automotive repair shops, these hoses are commonly used for welding exhaust systems, frames, and other components. In manufacturing, they play a crucial role in metal fabrication, helping to cut, weld, and shape various metal parts.

In addition to welding, oxy acetylene hoses are also used for cutting metal. The high-temperature flame produced by the oxygen-acetylene mix allows for precise and efficient metal cutting, making these hoses a valuable tool in many industrial settings.

Choosing the Right Oxy Acetylene Hose for Your Needs

When selecting an oxy acetylene hose, it's essential to consider factors such as hose length, diameter, material, and the price of twin welding hose. By choosing the right hose for your specific application, you can ensure optimal performance and safety. Whether you're a professional welder or a hobbyist, investing in a high-quality oxy acetylene hose will enhance your welding experience and ensure the best results.

Explore the wide range of oxy acetylene hoses for sale today and find the perfect solution for your welding needs. With their superior durability, flexibility, and safety features, these hoses are the ideal choice for any welding or cutting application.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNeiegkeetenJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNeiegkeetenJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNeiegkeetenJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNeiegkeetenJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNeiegkeetenJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNeiegkeetenJul.16,2025