3 16 oxygen acetylene hose

Understanding the Importance of 3% Oxygen and Acetylene Hoses

In the world of welding and cutting, the choice of equipment and materials significantly affects the outcome of projects. One crucial component often overlooked is the hoses used to transport gases like oxygen and acetylene. Specifically, hoses that are specifically designed to handle a 3% oxygen content are of paramount importance in various industrial applications.

The Role of Oxygen and Acetylene in Welding

Oxygen and acetylene are two gases commonly used in oxy-acetylene welding and cutting processes. When mixed, they create a flame capable of reaching high temperatures, allowing metals to be joined or cut effectively. The unique properties of these gases lead to a wide range of applications in manufacturing, construction, and repair industries. However, the efficiency and safety of these processes largely depend on the quality of the hoses that carry them.

Why 3% Oxygen Hoses?

The specification of 3% oxygen hose refers to hoses that can manage small concentrations of oxygen without degrading or becoming a hazard. This is particularly relevant for applications involving slight adjustments in oxygen levels, which are sometimes needed to accommodate different types of metal or varying thicknesses. Using a hose designed for these conditions ensures that the gases remain uncontaminated and that the integrity of the welding operation is maintained.

Material and Construction

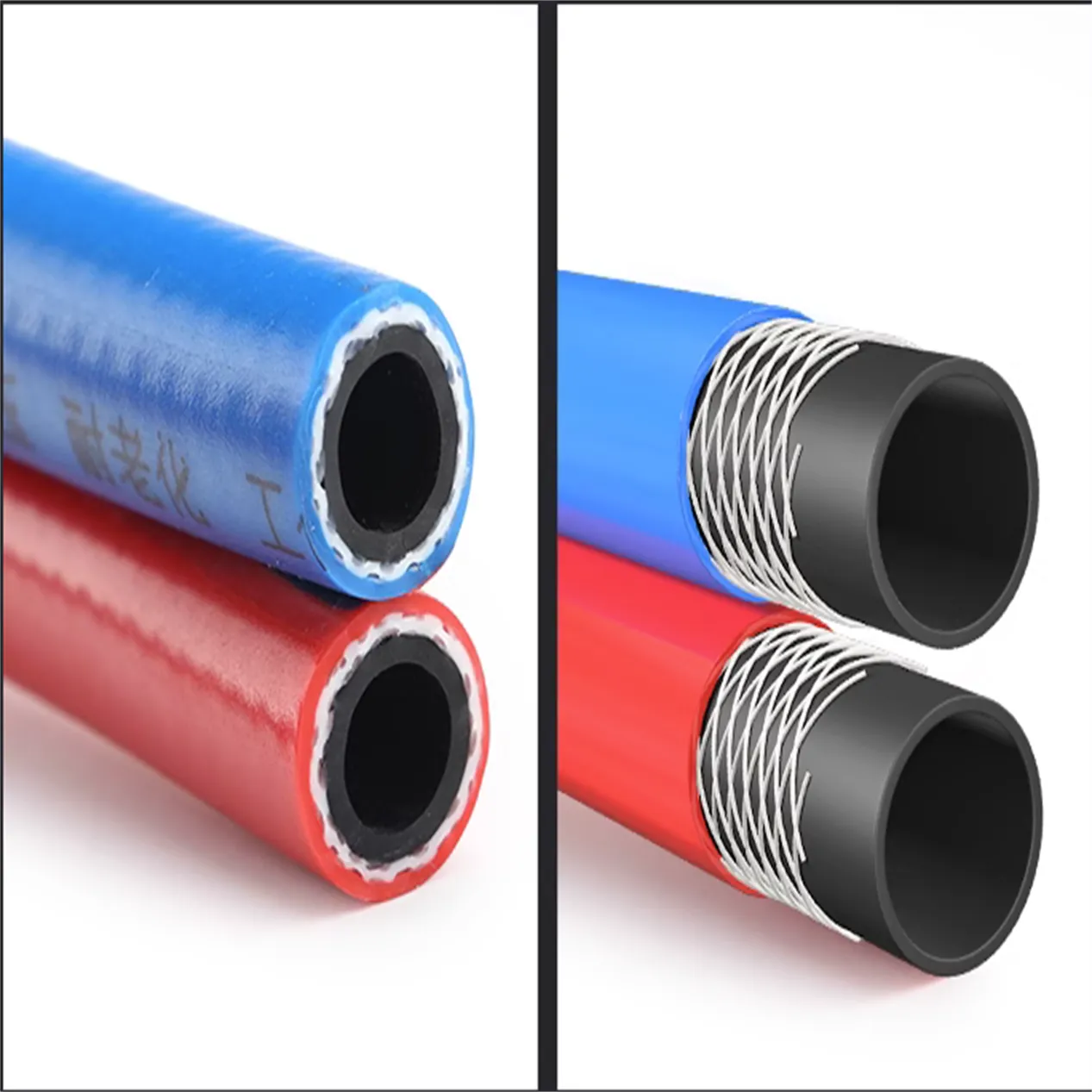

3 16 oxygen acetylene hose

Hoses constructed to handle 3% oxygen are typically made from materials that exhibit high resistance to oxidation and are capable of withstanding high pressures. Rubber, PVC, and synthetic composites are common choices, but they must be reinforced to avoid wear and tear over time. The construction of these hoses includes stringent quality controls to ensure they can operate safely under extreme conditions without degrading or leaking.

Additionally, the fittings and connectors used with these hoses must also be compatible with both oxygen and acetylene to ensure safety and efficiency. Mismatched materials can lead to dangerous reactions, and thus, ensuring compatibility through the selection of appropriate components is vital.

Safety Considerations

Safety is paramount when working with gases like oxygen and acetylene. The presence of oxygen even at 3% can enhance flammability, making it crucial for hoses to be inspected regularly for signs of damage or wear. Any abrasive conditions or exposure to extreme temperatures can weaken the hose's structure, increasing the risk of leaks or bursts.

Furthermore, workers must be trained in the proper handling and maintenance of these hoses. Understanding safe practices, including the correct storage of hoses, periodic maintenance checks, and awareness of potential hazards, can significantly reduce risks associated with gas welding operations.

Conclusion

In summary, understanding the role of 3% oxygen and acetylene hoses is essential for anyone involved in welding and cutting operations. These hoses are more than just conduits for gas; they are pivotal for ensuring that work is performed safely and efficiently. By prioritizing quality in hose selection and adhering to safety protocols, industries can achieve optimal performance in their welding and cutting tasks. As technology continues to advance, the importance of high-quality hoses in maintaining safety and efficiency will remain a critical focus in industrial applications.

-

Unveiling the Landscape of PVC Air Hoses and Comparative AnalysisNewsJun.24,2025

-

Unraveling the World of Specialized Braided Hoses and Their AlternativesNewsJun.24,2025

-

The Essential Role of PVC Hoses in Air - Related SystemsNewsJun.24,2025

-

Precision - Engineered Tubing and Braiding SolutionsNewsJun.24,2025

-

Pneumatic Tubing and Braided Hoses: Powering Industrial OperationsNewsJun.24,2025

-

Comparative Analysis and Insights into Air Hoses: PVC vs Rubber and BeyondNewsJun.24,2025