Leading Manufacturers of PVC Steel Wire Hoses for Various Applications

Understanding PVC Steel Wire Hose Manufacturers

The rise of the PVC steel wire hose in various industrial applications has paved the way for a growing number of manufacturers specializing in this versatile product. PVC (Polyvinyl Chloride) is a widely used synthetic plastic polymer, known for its durability, flexibility, and resistance to a range of chemicals. When reinforced with steel wire, the hose becomes much stronger and more resilient, making it ideal for applications requiring high pressure, increased stability, and extended lifespan.

What is PVC Steel Wire Hose?

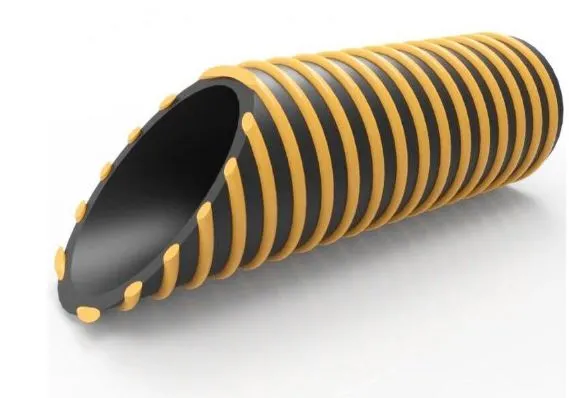

PVC steel wire hose is a composite product that combines PVC with embedded steel wires. The PVC layer provides excellent resistance to weather, aging, and abrasion, while the steel wire reinforcement enhances the hose's ability to withstand high pressures and prevents kinking. This combination makes it suitable for a breadth of applications, from agricultural irrigation to construction and mining.

Key Features

1. High Pressure Resistance One of the most notable features of PVC steel wire hoses is their ability to handle high-pressure environments. This makes them ideal for hydraulic applications and other industries where pressure fluctuations are common.

2. Durability The combination of PVC and steel wire results in a hose that can withstand harsh environmental conditions. This durability is crucial for applications in construction sites or other demanding settings.

3. Flexibility Despite its strength, PVC steel wire hose remains flexible, making it easy to handle and maneuver in various setups. This characteristic is particularly beneficial when working in tight or awkward spaces.

4. Chemical Resistance PVC is resistant to many chemicals, and the steel wire reinforcement provides additional support against physical damage, making the hose suitable for transporting various fluids and gases.

Manufacturing Process

pvc steel wire hose manufacturers

Manufacturers of PVC steel wire hoses typically follow a standardized process that ensures consistency and quality. The process begins with sourcing high-grade PVC resin and steel wire. Once the materials are gathered, the PVC is extruded to create the base of the hose. The steel wire is then spirally wound around the extruded PVC before another layer of PVC is applied. This multi-layer process enhances the strength and durability of the finished product.

After the hose is manufactured, it undergoes rigorous quality control tests. These tests check for pressure tolerance, flexibility, and resistance to various environmental factors. Manufacturers adhere to industry standards to ensure that their products meet customer expectations and regulatory requirements.

Choosing the Right Manufacturer

When selecting a PVC steel wire hose manufacturer, several factors should be considered to ensure you receive a high-quality product

1. Experience Look for manufacturers with a proven track record in the industry. Established manufacturers are likely to have perfected their processes and have extensive knowledge about the materials and production techniques.

2. Quality Certifications Choose manufacturers who adhere to international quality standards. Certifications such as ISO can be the hallmark of reliability and quality assurance.

3. Customization Options Not all hoses are created equal; different applications may require different specifications. A good manufacturer will offer customization options to meet specific client needs.

4. Customer Support A reliable manufacturer should provide excellent customer service, including technical support, product guidance, and after-sales support.

5. Reviews and Testimonials Investigating customer feedback can offer insights into the manufacturer's reputation and the durability of their products.

Conclusion

PVC steel wire hose manufacturers play a pivotal role in various industries by providing a product that combines flexibility, durability, and high pressure resistance. Understanding the unique features of these hoses and the manufacturing process can help businesses make informed decisions when selecting suitable products for their needs. By choosing the right manufacturer, businesses can ensure a reliable supply of high-quality hoses that will meet their operational demands efficiently. As industries continue to evolve, the importance of reliable, high-performance hoses cannot be overstated.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025