Қаң . 19, 2025 04:14

Back to list

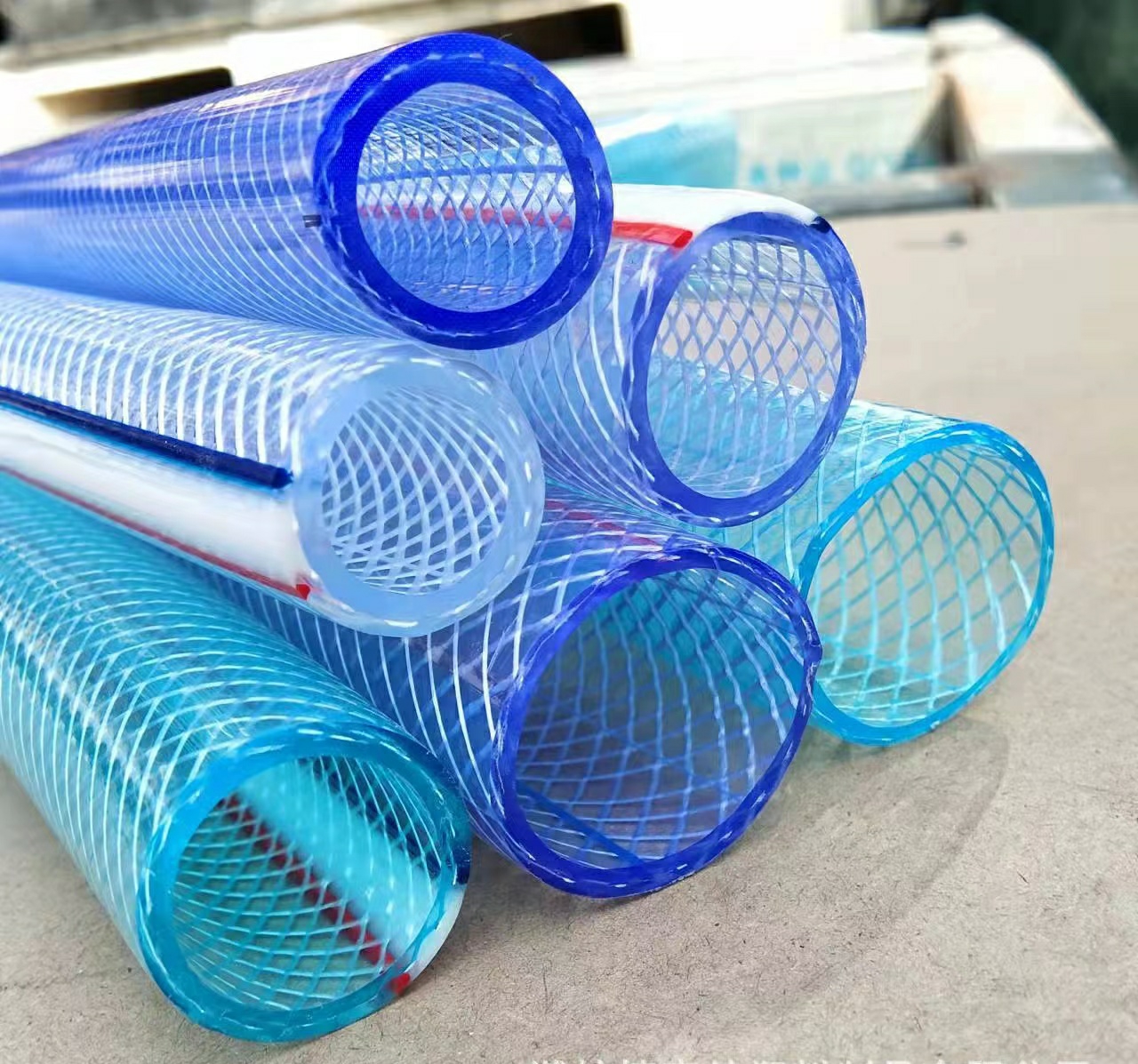

PVC Oxy Acetylene Twin Welding Hose

Flexible plastic hoses are essential components in a multitude of applications ranging from industrial machinery to everyday home use. When selecting the right size, understanding their dimensions and applications can significantly improve efficiency, safety, and performance.

Expert Insights on Choosing the Right Hose Size John Smith, a seasoned engineer specializing in fluid dynamics, advises “Always consider the working pressure and temperature of the fluid. Many make the mistake of selecting a hose based purely on ID without considering these aspects, which can lead to premature failure.” Furthermore, John suggests consulting with manufacturers for specific applications. Since many offer custom solutions, they can provide expert recommendations based on both size requirements and material suitability, ensuring the hose performs optimally over its expected lifespan. Building Trust with Quality Assurance When purchasing flexible plastic hoses, ensure they meet industry standards such as ISO or ASTM guidelines. These certifications guarantee that the hose has undergone rigorous testing for pressure resistance, temperature, and material safety, providing assurance in its capability and durability. Suppliers with a long-standing reputation and positive reviews often offer reliable products. It is advisable to request a sample for testing in your specific application before committing to large purchases, especially when dealing with new suppliers. This not only builds trust but minimizes risk and ensures that the products perform as expected. Conclusion Importance of Informed Selection Choosing the correct size for flexible plastic hoses is not just a matter of matching diameter dimensions. It necessitates an understanding of the fluid dynamics involved, material characteristics, and specific environmental conditions of their use. By leveraging expertise from industry professionals, consulting manufacturer resources, and selecting products from trusted suppliers, businesses can ensure efficient, safe, and cost-effective operations. Investing the time to research and select appropriately sized flexible plastic hoses pays dividends in terms of performance and reliability, ultimately influencing the bottom line positively. In an ever-evolving market, remaining informed and discerning ensures that your operation stands on a foundation of quality and efficiency.

Expert Insights on Choosing the Right Hose Size John Smith, a seasoned engineer specializing in fluid dynamics, advises “Always consider the working pressure and temperature of the fluid. Many make the mistake of selecting a hose based purely on ID without considering these aspects, which can lead to premature failure.” Furthermore, John suggests consulting with manufacturers for specific applications. Since many offer custom solutions, they can provide expert recommendations based on both size requirements and material suitability, ensuring the hose performs optimally over its expected lifespan. Building Trust with Quality Assurance When purchasing flexible plastic hoses, ensure they meet industry standards such as ISO or ASTM guidelines. These certifications guarantee that the hose has undergone rigorous testing for pressure resistance, temperature, and material safety, providing assurance in its capability and durability. Suppliers with a long-standing reputation and positive reviews often offer reliable products. It is advisable to request a sample for testing in your specific application before committing to large purchases, especially when dealing with new suppliers. This not only builds trust but minimizes risk and ensures that the products perform as expected. Conclusion Importance of Informed Selection Choosing the correct size for flexible plastic hoses is not just a matter of matching diameter dimensions. It necessitates an understanding of the fluid dynamics involved, material characteristics, and specific environmental conditions of their use. By leveraging expertise from industry professionals, consulting manufacturer resources, and selecting products from trusted suppliers, businesses can ensure efficient, safe, and cost-effective operations. Investing the time to research and select appropriately sized flexible plastic hoses pays dividends in terms of performance and reliability, ultimately influencing the bottom line positively. In an ever-evolving market, remaining informed and discerning ensures that your operation stands on a foundation of quality and efficiency.

Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE