air pvc pipe

Understanding Air PVC Pipes Applications, Advantages, and Best Practices

In today's world, the efficiency of piping systems is crucial for various industrial and commercial applications. One of the most versatile materials that have gained popularity in these systems is PVC, particularly when used for transporting air. Air PVC pipes are designed specifically for air distribution systems, and their unique properties offer a plethora of advantages. This article delves into the characteristics, applications, benefits, and best practices of using air PVC pipes.

What are Air PVC Pipes?

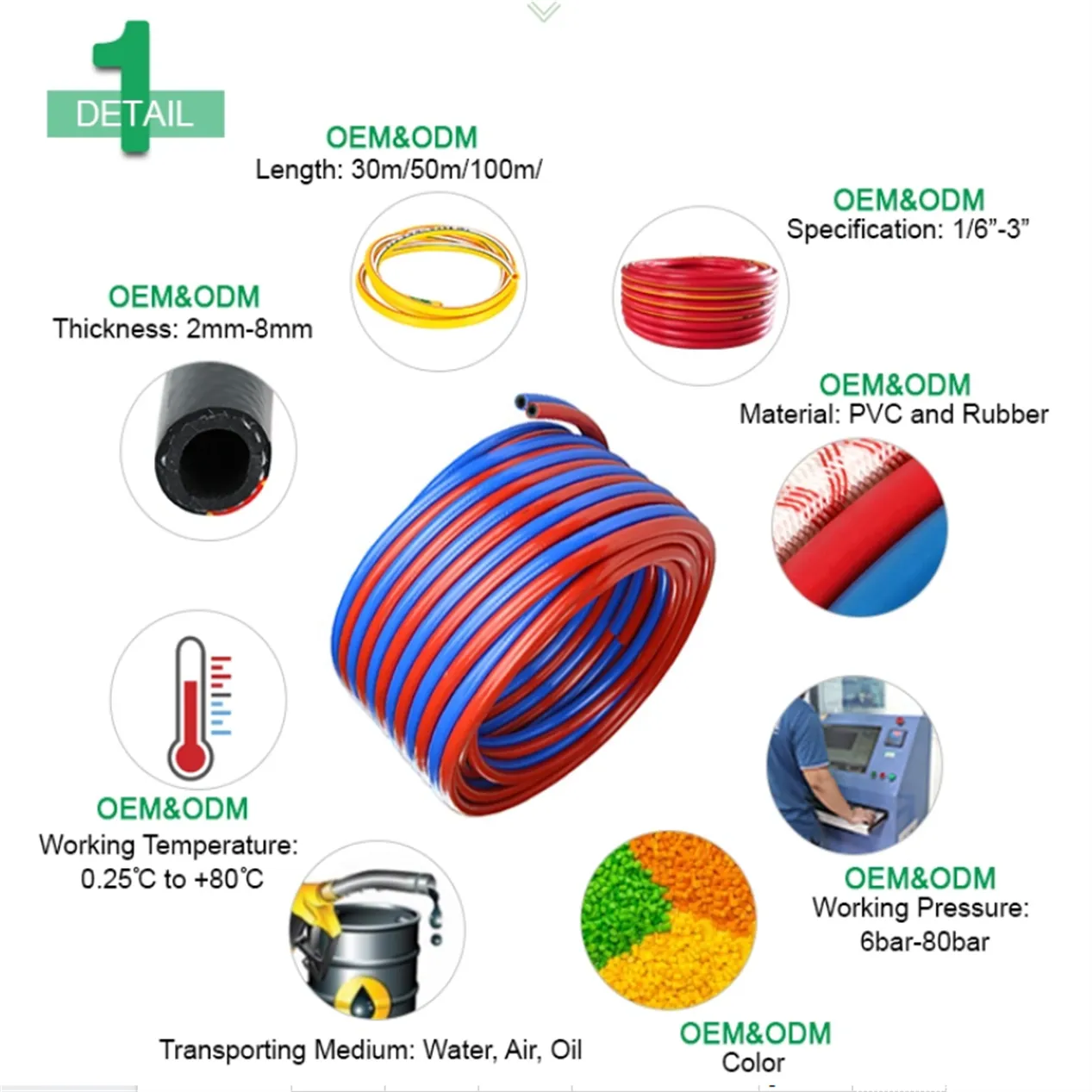

Air PVC pipes are cylindrical tubes made from polyvinyl chloride (PVC) polymer, specifically engineered to handle compressed air and other gaseous applications. These pipes are commonly manufactured in various diameters and wall thicknesses, making them suitable for different pressure levels and operational environments. PVC's inherent non-corrosive properties and lightweight nature make it an attractive option compared to traditional material choices like metal or concrete.

Applications of Air PVC Pipes

Air PVC pipes are utilized in a variety of settings, including but not limited to

1. Industrial Compressed Air Systems These pipes are frequently employed in factories and workshops where compressed air is essential for operating pneumatic tools, machinery, and other equipment.

2. HVAC Systems Air PVC pipes serve as ductwork in heating, ventilation, and air conditioning systems, effectively transporting air throughout commercial and residential buildings.

3. Aquaponics and Hydroponics In agricultural applications, air PVC pipes are used for aeration systems that deliver oxygen to aquatic life and plant roots, promoting healthy growth.

4. Wastewater Treatment In certain treatment facilities, air PVC pipes are employed to facilitate aeration processes, enhancing the efficiency of biological treatments.

5. Automotive and Aerospace Industries These industries utilize air PVC pipes for fuel vapor recovery systems and other applications, leveraging their lightweight and corrosion-resistant properties.

Advantages of Air PVC Pipes

There are several reasons why air PVC pipes have become a preferred choice for transporting air and gases

air pvc pipe

2. Lightweight Construction The lightweight nature of PVC makes it easier and cheaper to transport, handle, and install compared to heavier materials.

3. Chemical Resistance Air PVC pipes resist various chemicals and solvents, making them suitable for diverse applications without the risk of degradation.

4. Smooth Interior Surface The smoothness of PVC pipes minimizes friction loss, improving airflow efficiency and reducing energy consumption in compressed air systems.

5. Cost-Effectiveness Generally, PVC pipes are more affordable than metal counterparts and offer a favorable return on investment due to their durability and low maintenance needs.

6. Ease of Installation The lightweight and flexible structure of air PVC pipes allow for straightforward installation, often requiring fewer specialized tools and labor.

Best Practices for Using Air PVC Pipes

To maximize the benefits of air PVC pipes, it is important to adhere to best practices

1. Correct Sizing Ensure that the pipes are correctly sized for the intended application to prevent issues related to pressure loss or insufficient airflow.

2. Secure Connections Use proper fittings and adhesives to secure connections and avoid leaks that could compromise system efficiency.

3. Routine Inspections Regularly inspect the piping system for any signs of wear or damage, addressing issues promptly to maintain optimal performance.

4. Temperature Considerations Be aware of temperature limitations for PVC pipes; they should not be exposed to extreme heat that could compromise their structural integrity.

5. Avoiding UV Exposure If used outdoors, ensure that air PVC pipes are protected from prolonged sunlight exposure, which can lead to brittleness over time.

In conclusion, air PVC pipes represent a robust solution for transporting air in various applications. Their lightweight, corrosion-resistant, and cost-effective nature, combined with a variety of potential uses, makes them an essential component in both industrial and commercial settings. By following best practices, practitioners can ensure the longevity and effectiveness of their air PVC piping systems, contributing to enhanced operational efficiency and reduced costs.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025