Understanding Vacuum Ducting Systems for Efficient Industrial Applications and Technologies

Understanding Vacuum Ducting An Essential Component in Industrial Applications

In the modern industrial landscape, efficiency and precision are paramount. One of the critical elements that contributes to enhanced productivity in various sectors, including manufacturing, automotive, and pharmaceuticals, is vacuum ducting. This specialized system not only plays a crucial role in material handling but also improves the overall operational environment. In this article, we will delve into what vacuum ducting is, its applications, benefits, and considerations for installation and maintenance.

What is Vacuum Ducting?

Vacuum ducting involves the use of pipes, tubes, and fittings designed to transport air, gases, or dust particles from one location to another using a vacuum system. The primary function of vacuum ducting is to create an efficient pathway for the movement of materials, thereby minimizing the risk of contamination and promoting a cleaner working environment. The ducts are typically made of durable materials such as PVC, stainless steel, or metal, depending on the specific requirements of the application.

Applications of Vacuum Ducting

Vacuum ducting systems are widely employed across various industries. In manufacturing plants, these systems facilitate the removal of dust and other byproducts generated during production processes. In the automotive industry, vacuum ducting is essential for handling lightweight materials, ensuring that both manufacturing and assembly lines operate smoothly. In the pharmaceutical sector, it is used to maintain cleanliness and adhere to stringent hygiene standards by managing the movement of powders and granules.

Moreover, vacuum ducting is also prevalent in the food processing industry, where it is utilized to handle dry ingredients and maintain the quality of products

. The ability to transport materials without exposure to external contaminants is invaluable in these environments.Benefits of Using Vacuum Ducting

The adoption of vacuum ducting systems comes with numerous advantages

1. Enhanced Cleanliness By effectively removing dust and airborne particles, vacuum ducting contributes toa cleaner production environment, reducing the risk of contamination and improving product quality.

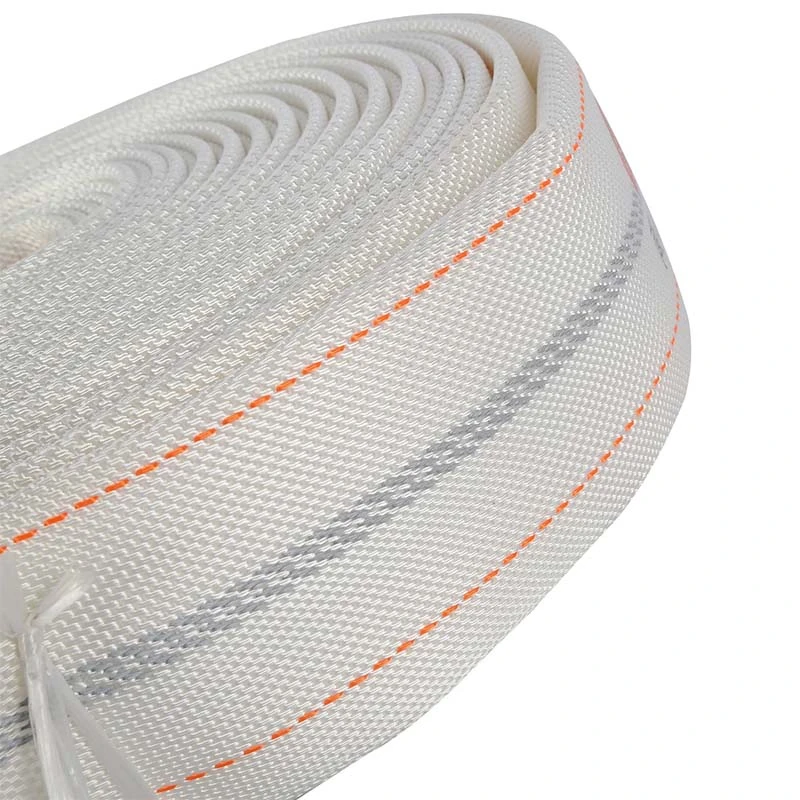

vacuum ducting

2. Increased Safety This system minimizes manual handling of hazardous substances, thereby reducing the potential for accidents and exposure-related health issues among workers.

3. Improved Efficiency Vacuum ducting facilitates the quick and efficient transport of materials, which can significantly enhance the productivity of manufacturing and processing operations.

4. Flexibility Vacuum ducting systems can be designed and configured to meet the specific needs of various applications, allowing for customization based on the size, shape, and characteristics of the materials being handled.

5. Cost-Effective While the initial installation might require an investment, the long-term benefits, including lower operational costs and reduced waste, make vacuum ducting a cost-effective solution.

Considerations for Installation and Maintenance

When implementing a vacuum ducting system, careful planning is essential. Factors such as the type of materials to be transported, the layout of the facility, and the required airflow rate must be considered for optimal performance. Additionally, regular maintenance is crucial for ensuring the longevity and efficiency of the system. This includes routine inspections, cleaning of ducts, and checking for any leaks or blockages that could impede airflow.

Furthermore, selecting the right materials for the ducting system is vital. The choice between rigid and flexible ducting should be based on factors such as application requirements, space constraints, and budgetary considerations.

Conclusion

Vacuum ducting is a fundamental component in numerous industrial applications, providing a reliable solution for material handling while promoting a cleaner, safer, and more efficient working environment. With its versatility and numerous benefits, understanding the role of vacuum ducting can empower businesses to optimize their operations and maintain high standards of quality and safety. As industries continue to evolve, the importance of effective vacuum ducting systems will only grow, making it a critical area of focus for engineers and facility managers alike.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025