Tubing for Vacuum Pumps - Quality Solutions for Optimal Performance

Tubing for Vacuum Pumps An Essential Component in Creating Optimal Vacuum Conditions

When it comes to the efficient operation of vacuum systems, tubing plays a crucial role in maintaining the integrity and performance of vacuum pumps. Vacuum pumps are designed to remove air and gases from a sealed environment, creating a vacuum that is essential for various applications, including laboratory experiments, industrial processes, and packaging systems. The type of tubing used in conjunction with these pumps can significantly influence the effectiveness and reliability of the vacuum.

Tubing for Vacuum Pumps An Essential Component in Creating Optimal Vacuum Conditions

Additionally, the diameter of the tubing is an important factor to consider. Larger diameter tubing can facilitate higher flow rates and reduce resistance, leading to better vacuum performance. However, excessively large tubing can cause unnecessary space and weight, while too small a diameter can restrict airflow and lead to inefficient pumping. The ideal diameter should strike a balance between flow capacity and practicality, ensuring that the vacuum pump operates optimally.

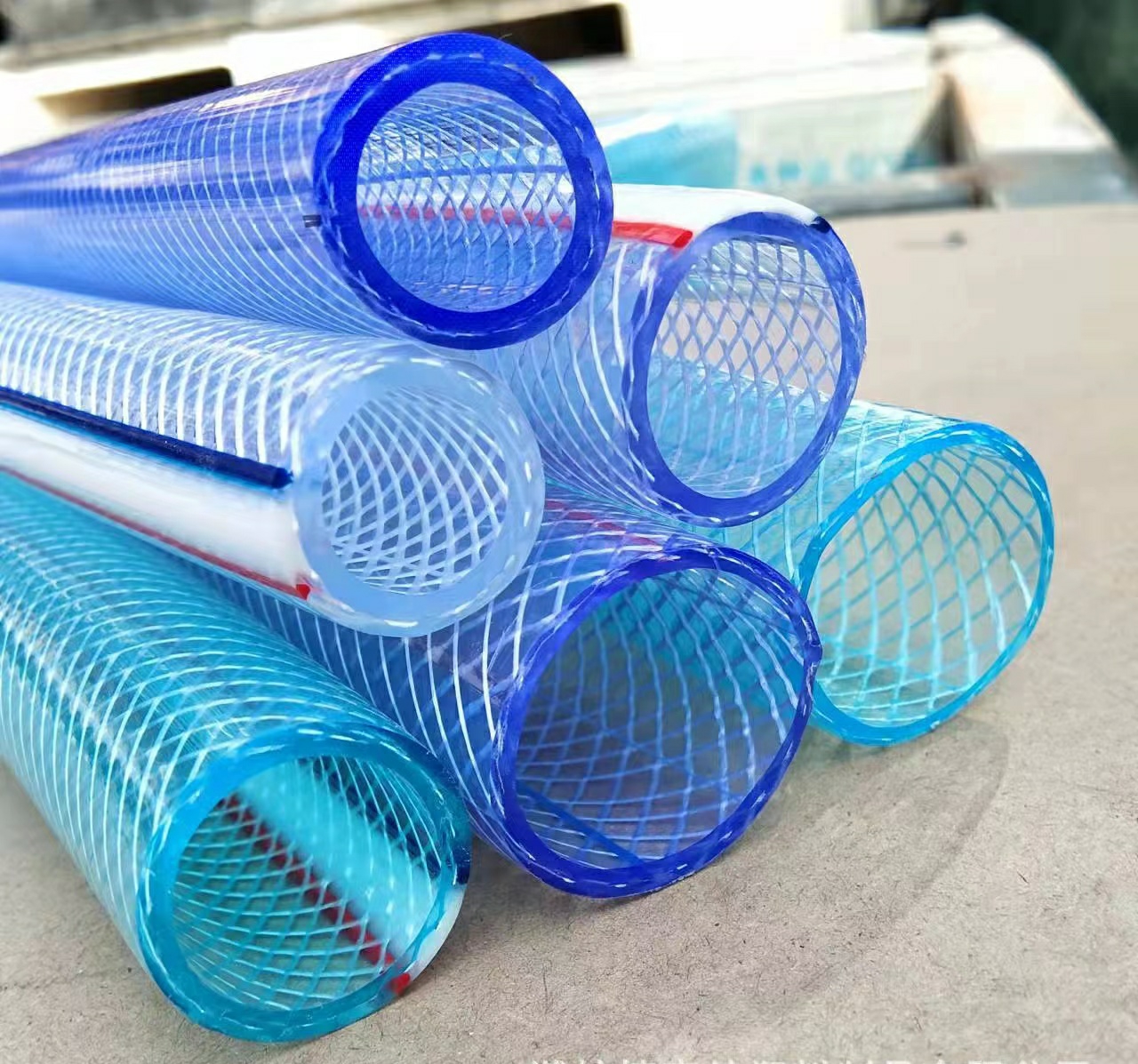

tubing for vacuum pump

The length of the tubing also needs to be addressed. Longer runs of tubing can introduce additional resistance and lead to pressure losses, which can compromise the vacuum level. When setting up a vacuum system, it's advisable to minimize the distance between the vacuum pump and the work area. In cases where longer tubing is required, it is essential to select smooth, high-quality tubing that reduces turbulence and allows for efficient gas flow.

Another consideration is the fitting and connection points along the tubing. Proper seals and secure fittings are vital to prevent leaks that could undermine the vacuum level. Many systems use clamps, barbs, or specialized connectors to ensure airtight seals. It's critical to evaluate these fittings regularly and replace any worn or damaged components to maintain optimal vacuum performance.

In conclusion, tubing for vacuum pumps is an essential aspect of creating and sustaining efficient vacuum conditions. By selecting the appropriate material, diameter, length, and ensuring secure connections, users can enhance the effectiveness and reliability of their vacuum systems. Investing in high-quality tubing can lead to improved performance and longer operational life for vacuum pumps, making it a crucial component in any vacuum application.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025