Understanding the Pressure Ratings of Braided PVC Hoses for Efficient Use

Understanding Braided PVC Hose Pressure Ratings

Braided PVC hoses have become an essential component in various industries due to their versatility, flexibility, and durability. Unlike traditional rubber hoses, braided PVC hoses incorporate a layer of reinforced material that provides added strength and resilience. One of the key factors to consider when selecting a braided PVC hose for a specific application is its pressure rating. In this article, we will explore what pressure ratings mean, why they are important, and how to choose the right braided PVC hose for your needs.

What is a Pressure Rating?

A pressure rating refers to the maximum amount of internal pressure that a hose can safely withstand during operation. It is typically expressed in pounds per square inch (PSI) or bars. The pressure rating is essential because exceeding this limit can lead to hose failure, potentially causing leaks, ruptures, and even dangerous mishaps. Therefore, understanding the pressure rating is crucial for ensuring the safe and effective use of braided PVC hoses in various applications.

Factors Influencing Pressure Ratings

Several factors influence the pressure rating of braided PVC hoses. These include the hose's diameter, wall thickness, the type of reinforcement material used, and the temperature of the medium being transported. Generally, a larger diameter hose can handle higher pressures, while thicker walls provide additional strength. The reinforcement material, often nylon or polyester, plays a significant role in determining the hose's durability and pressure resistance.

Temperature also affects pressure ratings. Most braided PVC hoses come with a temperature rating that indicates the maximum temperature at which the hose can safely operate. Operating beyond this temperature can diminish the hose's integrity, leading to premature failure. Therefore, it is essential to consider both pressure and temperature ratings when selecting the right hose for your application.

Applications of Braided PVC Hoses

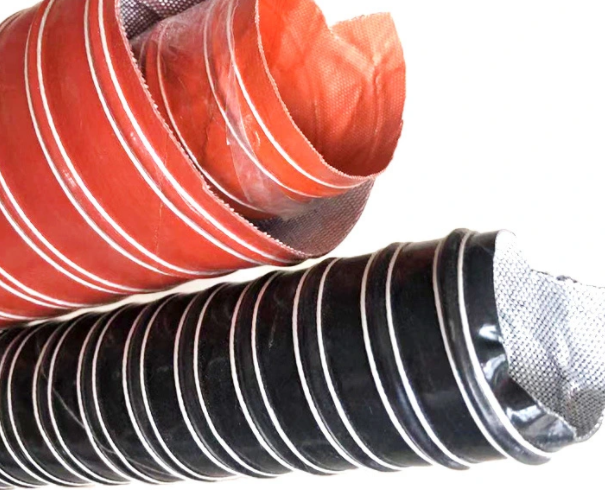

braided pvc hose pressure rating

Braided PVC hoses are commonly used across various industries, including agriculture, construction, automotive, and manufacturing

. Their remarkable ability to withstand high pressures while remaining flexible makes them ideal for transporting liquids, gases, and even solids.In the agricultural sector, braided PVC hoses are often employed for irrigation and fertilizers, providing reliable performance under varying pressure conditions. In construction and manufacturing, these hoses might be used for transferring water, chemicals, and other materials, where pressure ratings are critical for safety and efficiency. Their lightweight nature allows for easy handling, making them a popular choice across different sectors.

Choosing the Right Braided PVC Hose

When selecting a braided PVC hose, it is essential to determine your specific requirements. Begin by assessing the pressure and temperature of the substances you will be transporting. Consult the hose's technical specifications to ensure that its pressure rating aligns with your needs.

Additionally, consider the environmental conditions to which the hose will be exposed. Factors such as UV radiation, chemicals, and ozone exposure can affect the integrity of the hose over time. Ensure the chosen hose is designed to withstand these conditions for longevity.

Finally, always purchase from reputable manufacturers or suppliers to guarantee the quality and performance of the hose. Proper selection and maintenance will not only enhance the lifespan of the braided PVC hose but also ensure safety and efficiency in your operations.

In conclusion, understanding the pressure ratings of braided PVC hoses is critical for effective usage in various applications. By considering the factors that influence these ratings and choosing the right hose for your needs, you can ensure safe and efficient performance in your operations.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025