פבר . 11, 2025 21:56

Back to list

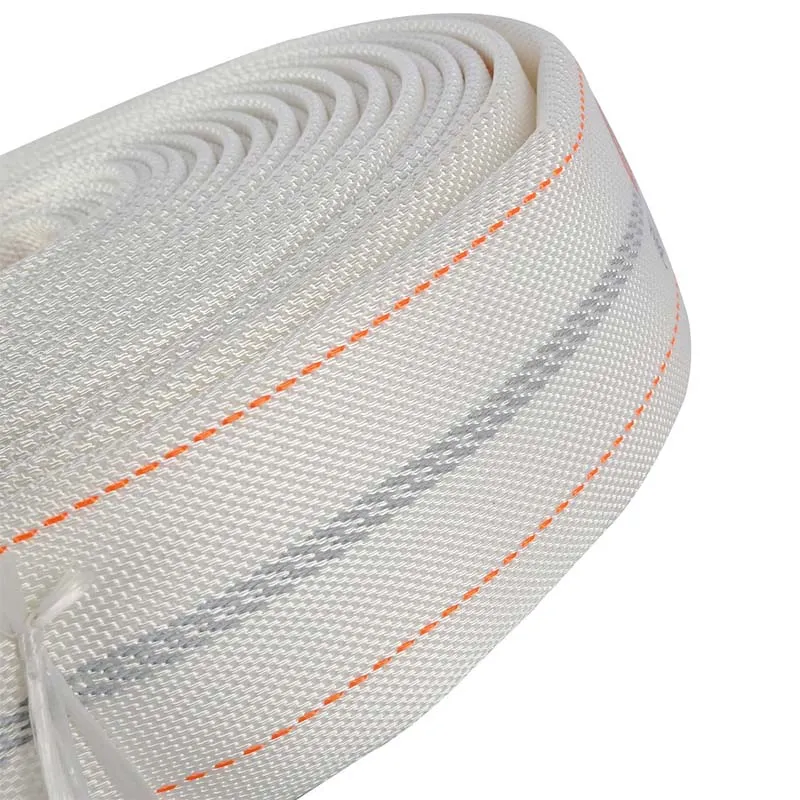

reinforced polyurethane air hose

In the world of industrial equipment, the choice of the right air hose is pivotal for ensuring efficiency, safety, and durability. Reinforced polyurethane air hoses have emerged as a top contender in this space, offering a blend of flexibility, resilience, and endurance under demanding conditions. This article aims to unpack the unique benefits, expert recommendations, and authoritative perspectives that surround the use of reinforced polyurethane air hoses in various applications.

Industry experts often endorse reinforced polyurethane air hoses for applications that demand reliability and efficiency. When selecting the right hose, it is essential to consider factors such as internal diameter, pressure rating, and temperature range. Professionals recommend opting for hoses with an adequate pressure rating that exceeds the operational requirement to ensure safety and performance. Additionally, check for compliance with industry standards and certifications, which signify adherence to safety and quality guidelines. Safety and Trustworthiness In terms of safety, reinforced polyurethane air hoses offer non-marking surfaces and resistance to static build-up, crucial in preventing accidents and ensuring workplace safety. Moreover, renowned manufacturers often accompany their products with warranties and customer support, cementing their commitment to trustworthiness and quality assurance. When choosing a supplier, prioritizing brands with a solid reputation for quality products and after-sale support can make a significant difference in ensuring reliable operation and peace of mind. Environmental Considerations From an environmental standpoint, polyurethane is a more sustainable option compared to other synthetic materials. It requires less energy to produce and can be recycled more efficiently. As industries increasingly prioritize sustainability, selecting air hoses that align with these values is becoming more critical. Thus, opting for reinforced polyurethane air hoses not only meets operational needs but also supports broader environmental objectives. Real-World Applications The versatility of reinforced polyurethane air hoses is apparent across various industries. In the automotive industry, they are instrumental in powering pneumatic tools for repairs and maintenance without leaving scratches or marks on vehicle surfaces. In construction, their ability to perform under high pressure and extreme conditions ensures that tools operate efficiently. Meanwhile, in the food and beverage industry, polyurethane’s non-toxic properties make these hoses ideal for transporting ingredients without contamination. In conclusion, the reinforced polyurethane air hose stands out as a superior choice for industries that demand flexibility, strength, and durability. Embracing the right tools is critical for enhancing productivity and ensuring safety—a truth well-understood by those who have experienced the benefits of reinforced polyurethane firsthand. As echoed by industry professionals, investing in quality air hoses is a sure path to operational excellence and long-term success.

Industry experts often endorse reinforced polyurethane air hoses for applications that demand reliability and efficiency. When selecting the right hose, it is essential to consider factors such as internal diameter, pressure rating, and temperature range. Professionals recommend opting for hoses with an adequate pressure rating that exceeds the operational requirement to ensure safety and performance. Additionally, check for compliance with industry standards and certifications, which signify adherence to safety and quality guidelines. Safety and Trustworthiness In terms of safety, reinforced polyurethane air hoses offer non-marking surfaces and resistance to static build-up, crucial in preventing accidents and ensuring workplace safety. Moreover, renowned manufacturers often accompany their products with warranties and customer support, cementing their commitment to trustworthiness and quality assurance. When choosing a supplier, prioritizing brands with a solid reputation for quality products and after-sale support can make a significant difference in ensuring reliable operation and peace of mind. Environmental Considerations From an environmental standpoint, polyurethane is a more sustainable option compared to other synthetic materials. It requires less energy to produce and can be recycled more efficiently. As industries increasingly prioritize sustainability, selecting air hoses that align with these values is becoming more critical. Thus, opting for reinforced polyurethane air hoses not only meets operational needs but also supports broader environmental objectives. Real-World Applications The versatility of reinforced polyurethane air hoses is apparent across various industries. In the automotive industry, they are instrumental in powering pneumatic tools for repairs and maintenance without leaving scratches or marks on vehicle surfaces. In construction, their ability to perform under high pressure and extreme conditions ensures that tools operate efficiently. Meanwhile, in the food and beverage industry, polyurethane’s non-toxic properties make these hoses ideal for transporting ingredients without contamination. In conclusion, the reinforced polyurethane air hose stands out as a superior choice for industries that demand flexibility, strength, and durability. Embracing the right tools is critical for enhancing productivity and ensuring safety—a truth well-understood by those who have experienced the benefits of reinforced polyurethane firsthand. As echoed by industry professionals, investing in quality air hoses is a sure path to operational excellence and long-term success.

Next:

Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE