Jan . 13, 2025 13:12

Back to list

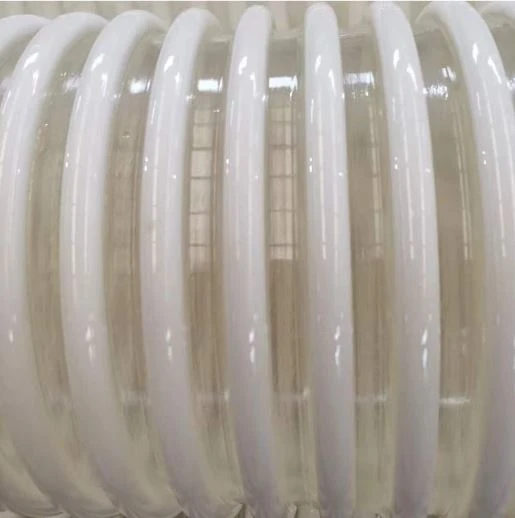

polyurethane tubings

Polyurethane tubings have revolutionized various industries with their superior performance attributes and versatility. Known for their exceptional resilience and adaptability, these tubings have become the go-to solution for many applications requiring robust and durable materials. Their unique chemical structure endows them with an exceptional level of flexibility, making them ideal for both dynamic and static tasks across myriad sectors.

In terms of expertise, engineers and technicians appreciate polyurethane tubings for their ease of installation and maintenance. Their lightweight nature simplifies handling and installation, reducing labor costs and the potential for on-site errors. The ability to mold these tubings into various shapes and sizes further enhances their application versatility, accommodating any specification or design requirement an operation might have. Authoritatively speaking, polyurethane has been extensively tested and verified for its performance, ensuring that its use in critical applications is thoroughly supported by empirical data. Regulatory approvals and certifications further enhance its trustworthiness, assuring industries that these tubings adhere to stringent safety and quality standards. When considering trustworthiness, numerous case studies and operational histories reveal the long-term benefits of investing in polyurethane tubings. Facilities using these tubes report enhanced operational efficiencies and cost savings over time, building a strong case for their reliability and value proposition. In conclusion, polyurethane tubings demonstrate a combination of resilience, versatility, and reliability that make them an unparalleled choice for diverse industrial applications. As companies continue to seek materials that offer durability and performance, polyurethane emerges as a leading candidate, consistently setting itself apart with its comprehensive benefits and proven track record in demanding environments. Investing in polyurethane tubings is a strategic decision backed by experience, expertise, and industry-wide recognition, promising significant returns both in operational efficiency and longevity.

In terms of expertise, engineers and technicians appreciate polyurethane tubings for their ease of installation and maintenance. Their lightweight nature simplifies handling and installation, reducing labor costs and the potential for on-site errors. The ability to mold these tubings into various shapes and sizes further enhances their application versatility, accommodating any specification or design requirement an operation might have. Authoritatively speaking, polyurethane has been extensively tested and verified for its performance, ensuring that its use in critical applications is thoroughly supported by empirical data. Regulatory approvals and certifications further enhance its trustworthiness, assuring industries that these tubings adhere to stringent safety and quality standards. When considering trustworthiness, numerous case studies and operational histories reveal the long-term benefits of investing in polyurethane tubings. Facilities using these tubes report enhanced operational efficiencies and cost savings over time, building a strong case for their reliability and value proposition. In conclusion, polyurethane tubings demonstrate a combination of resilience, versatility, and reliability that make them an unparalleled choice for diverse industrial applications. As companies continue to seek materials that offer durability and performance, polyurethane emerges as a leading candidate, consistently setting itself apart with its comprehensive benefits and proven track record in demanding environments. Investing in polyurethane tubings is a strategic decision backed by experience, expertise, and industry-wide recognition, promising significant returns both in operational efficiency and longevity.

Next:

Latest news

-

Durable PVC Air Hoses: Flexible & Reliable Industrial SolutionsNewsAug.29,2025

-

PVC Suction Hoses: Flexible, Durable Fluid Transfer SolutionsNewsAug.28,2025

-

Advanced Corrugated Pvc Hose Technology for Modern Industrial NeedsNewsAug.22,2025

-

Premium Fire Water Hose Solutions for Global IndustriesNewsAug.22,2025

-

Industrial Suppliers Guide to Premium Double Welding Hose SolutionsNewsAug.22,2025

-

Premium PU Pneumatic Hose Solutions for Industrial ApplicationsNewsAug.22,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE