Mar . 04, 2025 09:53

Back to list

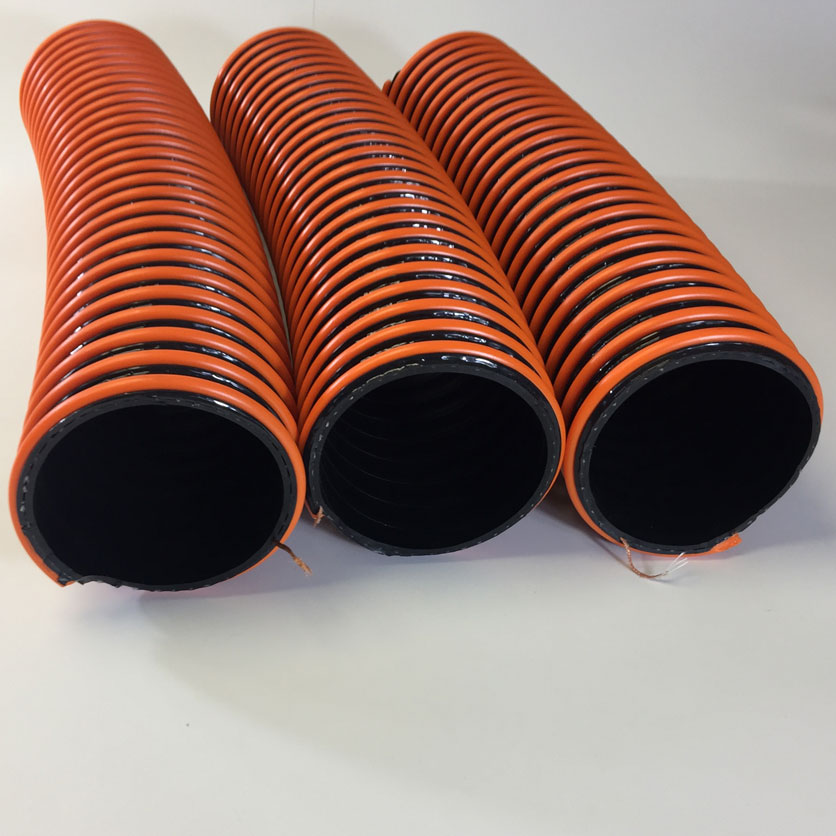

Diesel heater tube Aluminum Foil Tubes for Hot & Cold Air Distribution

Navigating the world of venting solutions for dryers, selecting the right duct can significantly impact your appliance’s efficiency and safety. Foil duct for dryers stands out for its affordability and ease of installation, making it a popular choice among homeowners and professionals alike. However, to fully leverage its benefits, understanding its application and maintenance is crucial.

In environments where pets are present, increased vigilance is required. Pet hair can easily make its way into laundry loads and consequently into the dryer duct system. Pet owners should adhere to a more aggressive cleaning schedule to mitigate the increased risk of blockage or fire. In recent years, regulations around dryer vents have become more stringent, and professionals recommend replacing foil ducts with rigid or semi-rigid ducting materials for new installations. These alternatives, although more expensive and complex to install, offer superior durability and safety features. They resist crushing, reducing the likelihood of traps that collect lint and create fire hazards. For those who already have foil ducts installed, it’s imperative to weigh the benefits of continuing with them versus transitioning to more robust options. Factors to consider include the frequency of dryer use, potential exposure to physical wear, and willingness to engage in regular maintenance checks. When it comes to enhancing both the efficiency and safety of your dryer, making informed decisions about the type of ducting used is critical. Foil ducts offer flexibility and low cost, appealing to a wide range of users, but they require diligent maintenance to avoid potential hazards. By committing to regular inspections and cleanings, and evaluating whether a more durable alternative might be appropriate, you can optimize the performance of your dryer while ensuring peace of mind regarding its safety. Ultimately, a foil duct for dryers is a viable option under the right conditions, provided users are committed to maintaining it properly and considering industry recommendations and safety guidelines.

In environments where pets are present, increased vigilance is required. Pet hair can easily make its way into laundry loads and consequently into the dryer duct system. Pet owners should adhere to a more aggressive cleaning schedule to mitigate the increased risk of blockage or fire. In recent years, regulations around dryer vents have become more stringent, and professionals recommend replacing foil ducts with rigid or semi-rigid ducting materials for new installations. These alternatives, although more expensive and complex to install, offer superior durability and safety features. They resist crushing, reducing the likelihood of traps that collect lint and create fire hazards. For those who already have foil ducts installed, it’s imperative to weigh the benefits of continuing with them versus transitioning to more robust options. Factors to consider include the frequency of dryer use, potential exposure to physical wear, and willingness to engage in regular maintenance checks. When it comes to enhancing both the efficiency and safety of your dryer, making informed decisions about the type of ducting used is critical. Foil ducts offer flexibility and low cost, appealing to a wide range of users, but they require diligent maintenance to avoid potential hazards. By committing to regular inspections and cleanings, and evaluating whether a more durable alternative might be appropriate, you can optimize the performance of your dryer while ensuring peace of mind regarding its safety. Ultimately, a foil duct for dryers is a viable option under the right conditions, provided users are committed to maintaining it properly and considering industry recommendations and safety guidelines.

Next:

Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE