Essential Guide to Choosing the Right Vacuum Pump Hose for Optimal Performance and Durability

Understanding Vacuum Pump Hoses A Critical Component of Industrial Applications

Vacuum pump hoses play a vital role in a wide range of industrial applications. These specialized hoses are designed to transport gases and vapors in vacuum systems, ensuring that processes such as material handling, packaging, and food processing operate smoothly and efficiently. In this article, we will explore the significance of vacuum pump hoses, their construction materials, and best practices for their use.

What is a Vacuum Pump Hose?

A vacuum pump hose is a flexible tube that connects various components of a vacuum system, such as pumps, valves, and machinery. Its primary purpose is to create and maintain a vacuum environment, allowing for the efficient transfer of air and other gases. These hoses are engineered to withstand significant pressure differences, enabling them to function effectively in both high and low-pressure situations.

Importance of Vacuum Pump Hoses

In industrial settings, vacuum systems are essential for numerous operations. For instance, in the packaging industry, vacuum technology is used to preserve food by removing air and extending the shelf life of products. In semiconductor manufacturing, vacuum pumps help maintain clean environments free from contaminants. Vacuum pump hoses facilitate the transfer of air and gases in these processes, making them indispensable for optimal performance.

Additionally, the proper construction of vacuum pump hoses ensures the safety and reliability of the entire vacuum system. Poor-quality hoses can lead to leaks, which may compromise the vacuum level and negatively impact operations. Moreover, a compromised hose can lead to hazardous situations, particularly in environments handling volatile substances.

Construction Materials

The materials used in the fabrication of vacuum pump hoses are crucial to their performance and durability. Common materials include rubber, PVC (polyvinyl chloride), and various types of plastics.

1. Rubber Known for its flexibility and resistance to extreme temperatures, rubber hoses are often used in a wide variety of applications. They can handle high levels of vacuum and pressure and provide excellent chemical resistance.

2. PVC Lightweight and cost-effective, PVC hoses are frequently used in less demanding applications. While they offer decent vacuum performance, they may not withstand extreme temperatures or aggressive chemicals as well as rubber.

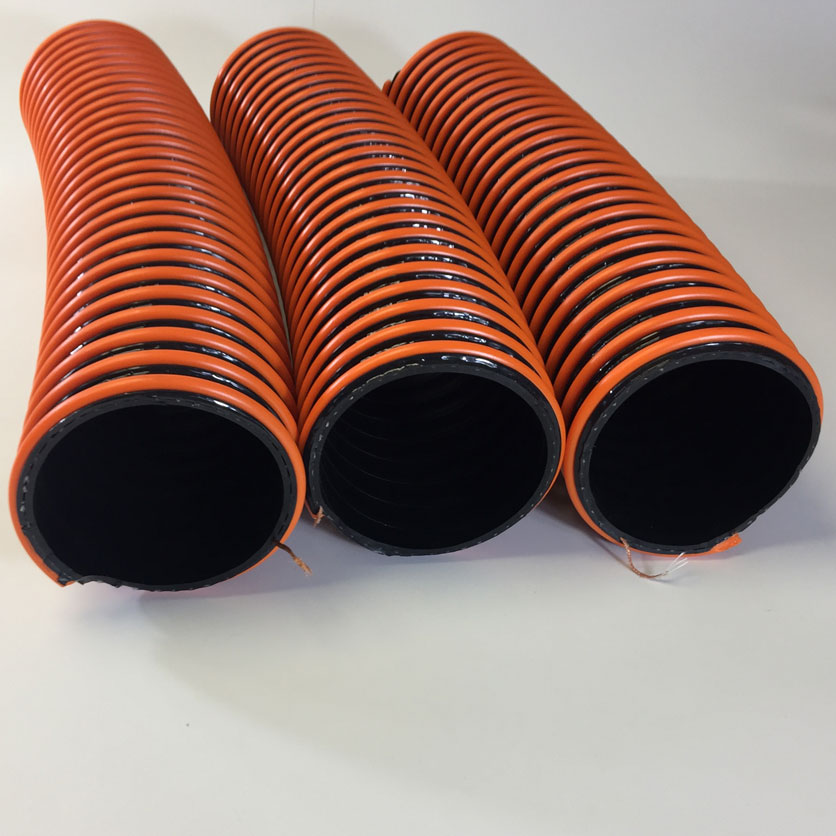

vacuum pump hose

3. Plastic Specialized plastic hoses, such as those made from polyurethane, can provide superior flexibility and cut-resistance. They are ideal for applications that require a lightweight solution without compromising on performance.

Different applications may require different materials, so it's essential to select the right hose based on the specific requirements of the vacuum system.

Best Practices for Using Vacuum Pump Hoses

1. Proper Selection Always choose the right type of hose for the application. Consider factors such as maximum vacuum level, temperature range, and chemical exposure.

2. Regular Maintenance Inspect hoses regularly for signs of wear, cracks, or leaks. Addressing issues promptly can prevent more significant problems down the line.

3. Correct Installation Ensure that hoses are properly installed to prevent kinks, which can restrict airflow and compromise vacuum levels.

4. Avoid Overstretching Be mindful not to stretch hoses past their capability, as overextending can lead to damage and failure.

5. Temperature Management Monitor the temperature of the surrounding environment to ensure that the hose materials do not degrade due to excessive heat.

Conclusion

Vacuum pump hoses are integral to the functionality of vacuum systems across diverse industries. Understanding their design, materials, and best practices can help businesses optimize their operations while ensuring safety and reliability. By investing in high-quality hoses and adhering to maintenance protocols, industries can sustain efficient and effective vacuum processes, enhancing productivity and ensuring the safety of both workers and products.

-

Unrivaled Performance and Applications of PU Pneumatic Hoses and TubesNewsJun.11,2025

-

The Transparent World of Industrial Tubing and Hosing SolutionsNewsJun.11,2025

-

The Intricate World of Pneumatic Conduits: Tubes and HosesNewsJun.11,2025

-

The Dynamic Landscape of Pneumatic Conduits: Unraveling Key ComponentsNewsJun.11,2025

-

The Diverse Applications and Significance of Transparent PVC TubingNewsJun.11,2025

-

High - Pressure Pneumatic Tubing and Systems: An In - Depth LookNewsJun.11,2025