Comparing PVC and Rubber Air Hoses for Durability and Flexibility

Comparing PVC and Rubber Air Hoses Which is Right for You?

When it comes to selecting air hoses for your pneumatic tools and applications, two of the most common materials on the market are PVC (Polyvinyl Chloride) and rubber. Each material comes with its own set of advantages and disadvantages, making the selection process crucial depending on your specific needs. In this article, we'll explore the characteristics, benefits, and limitations of both PVC and rubber air hoses to help you make an informed decision.

Properties of PVC Air Hoses

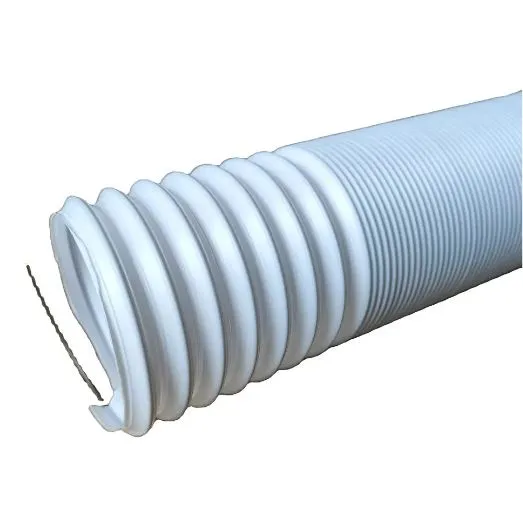

PVC air hoses are known for their lightweight and flexibility. They are often more affordable than rubber hoses and can be easily coiled for storage. Due to their structure, PVC hoses resist weathering and are suitable for various indoor and outdoor applications. Their smooth interior surface allows for a relatively unhindered airflow, which is essential for pneumatic tools that rely on consistent air pressure.

However, PVC hoses can become stiff in colder temperatures, affecting their performance and flexibility. Additionally, while they are generally resistant to abrasion, they may not have the same durability as rubber hoses when exposed to sharp objects or high temperatures. As such, PVC may not be the ideal choice for heavy-duty industrial applications that demand a hose with high tensile strength and resilience.

Benefits of Rubber Air Hoses

On the other hand, rubber air hoses are favored for their superior durability and resistance to extreme temperatures, making them ideal for challenging environments. They can withstand high pressures and are less likely to crack or degrade when subjected to rigorous use. Rubber hoses also resist kinking, which can be a significant advantage in keeping air flow consistent during operation, especially in professional and commercial settings.

air hose pvc vs rubber

Rubber is also less prone to damage from oil or fuel spills, which is a major concern in automotive or mechanical applications. Although rubber air hoses are heavier and often more expensive than PVC options, their long lifecycle and ability to perform under demanding conditions justify the investment for many users.

Application Considerations

The choice between PVC and rubber air hoses ultimately depends on your specific application requirements. If you're a DIY enthusiast requiring a hose for light tasks around the home or for occasional outdoor use, a PVC air hose might be sufficient. Its lightweight nature makes it easy to handle and store, and the cost-effectiveness is an added benefit.

In contrast, if you're in an industrial setting or plan to operate in extreme conditions frequently, investing in a rubber air hose would be beneficial. Its durability, resistance to temperature changes, and ability to withstand high pressures make it a more suitable choice for heavy-duty work.

Conclusion

In summary, both PVC and rubber air hoses have their unique advantages and drawbacks. PVC hoses offer a cost-effective, lightweight solution for less demanding tasks, while rubber hoses provide the toughness and resilience needed for heavy-duty applications. When making your decision, consider factors such as budget, intended use, and environmental conditions. By evaluating these aspects carefully, you can choose the right type of air hose that best meets your needs and ensures reliable performance in your pneumatic tasks.

-

Unrivaled Performance and Applications of PU Pneumatic Hoses and TubesNewsJun.11,2025

-

The Transparent World of Industrial Tubing and Hosing SolutionsNewsJun.11,2025

-

The Intricate World of Pneumatic Conduits: Tubes and HosesNewsJun.11,2025

-

The Dynamic Landscape of Pneumatic Conduits: Unraveling Key ComponentsNewsJun.11,2025

-

The Diverse Applications and Significance of Transparent PVC TubingNewsJun.11,2025

-

High - Pressure Pneumatic Tubing and Systems: An In - Depth LookNewsJun.11,2025