Selecting the Right Tubing for Optimal Vacuum Pump Performance and Efficiency

Tubes for Vacuum Pumps A Comprehensive Guide

Vacuum pumps are essential tools in various industrial and laboratory applications, enabling the removal of air and other gases from sealed chambers. To optimize the efficiency of these systems, the selection of appropriate tubing is crucial. This article explores the different types of tubing suitable for vacuum pumps, their materials, benefits, and application considerations.

Types of Tubing for Vacuum Applications

When dealing with vacuum systems, not all tubing is suitable. The most common types of tubing are rigid and flexible tubes, each serving specific needs

1. Rigid Tubing This type is often made from materials such as glass or metal. Rigid tubes are ideal for high vacuum applications because they can withstand higher pressure differences without collapsing. Glass tubes provide excellent visibility, allowing users to monitor processes, while metal tubes offer higher durability and resistance to chemical interactions.

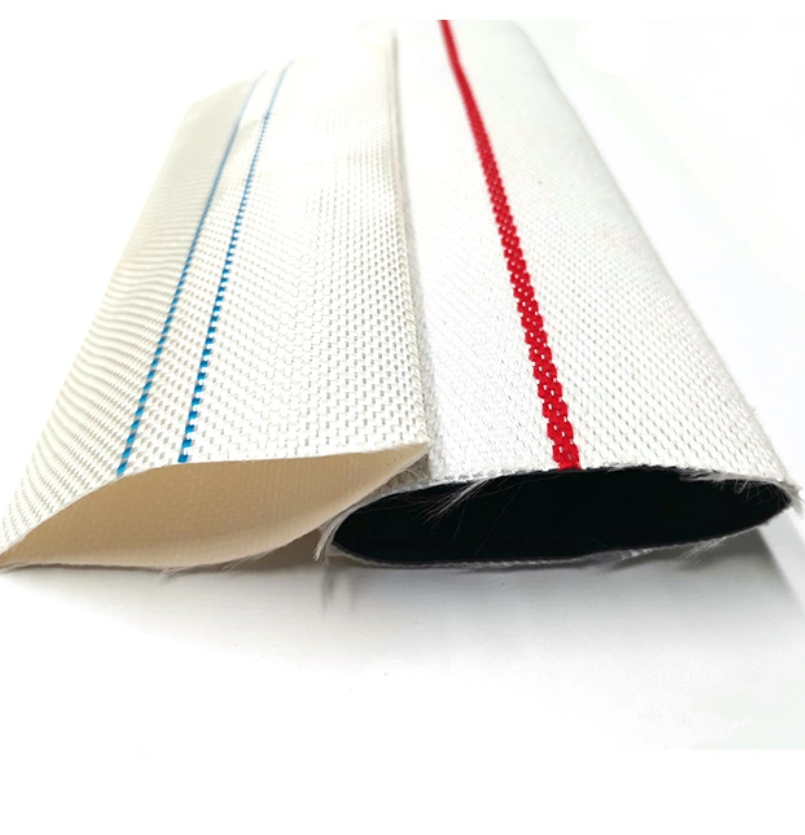

2. Flexible Tubing Commonly made from rubber, silicone, or various plastics, flexible tubing is generally easier to install and can accommodate dynamic movements or vibrations. However, it must be chosen carefully to ensure it can withstand the vacuum pressure without deforming or collapsing. Specialty materials like PTFE (Teflon) are often used in flexible configurations for their superior chemical resistance and temperature stability.

Materials for Vacuum Tubing

The choice of material for vacuum tubing is critical not just for performance but also for compatibility with the substances being handled. Common materials include

- Silicone Known for its flexibility and temperature resistance, silicone tubing is often used in laboratory settings. However, it may not perform well under extreme vacuum conditions.

- PTFE (Teflon) This is a popular choice as it offers excellent chemical resistance and can operate effectively at higher temperatures. PTFE’s low friction coefficient also reduces the risk of contamination.

- Polyethylene and Polypropylene These plastic materials are lightweight and cost-effective

. They are generally used in low to medium vacuum applications but may not be suitable for high-stress environments.tubing for vacuum pump

- Stainless Steel Often used in high-vacuum systems, stainless steel tubing is known for its strength and durability. It is resistant to corrosion and can handle higher temperatures and pressures, making it ideal for industrial applications.

Choosing the Right Tubing

When selecting tubing for a vacuum pump, several factors must be considered

- Pressure Rating Ensure that the tubing can withstand the maximum vacuum pressure that will be employed. Check the manufacturer’s specifications for ratings.

- Chemical Compatibility If the system handles corrosive substances, select materials that can withstand these chemicals without degrading over time.

- Operating Temperature Ensure that the tubing material can handle the temperature range of the application without losing its structural integrity.

- Bend Radius Flexible tubing should have a sufficient bend radius to prevent kinking, which could lead to vacuum losses.

- Sealing and Fittings Proper sealing is crucial in vacuum systems. Ensure that the joints and fittings are compatible and create airtight seals to prevent leaks.

Conclusion

Choosing the right tubing for vacuum pumps is integral to the efficiency and effectiveness of the system. By understanding the types of tubing available, the materials they are made from, and the key factors for selection, users can optimize their vacuum systems for better performance and longevity. Whether for industrial use or in a laboratory setting, investing time in choosing the appropriate tubing will lead to improved operational efficiency and reliability. Always consult with manufacturers or vacuum system specialists if uncertain about the best options for your specific needs.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025