Flexible PVC Braided Tubing for Durable and Versatile Applications in Various Industries

Understanding PVC Braided Tubing Applications and Benefits

PVC braided tubing is a highly versatile and durable product that has gained widespread use in various industries. Made from polyvinyl chloride (PVC) and reinforced with a braided fiber mesh, this type of tubing is known for its strength, flexibility, and resistance to various environmental factors. In this article, we will explore the composition, applications, and benefits of PVC braided tubing, as well as considerations for choosing this product for your specific needs.

Composition and Characteristics

PVC, a widely used synthetic plastic polymer, is known for its robustness and ability to handle a range of temperatures and chemicals. The braided mesh that reinforces PVC tubing adds an extra layer of durability, making it capable of withstanding high pressure without bursting. This design also ensures that the tubing remains flexible, allowing for ease of installation and movement without compromising its strength.

Additionally, PVC braided tubing is typically resistant to abrasion, UV radiation, and many chemicals, making it suitable for both indoor and outdoor applications. Its clarity allows for easy visibility of the flow within the tubing, an advantageous feature for monitoring purposes.

Applications

PVC braided tubing finds applications in a variety of sectors, including

1. Industrial Uses Industries such as manufacturing and construction utilize PVC braided tubing for transporting fluids and gases. Its strength and durability make it an ideal choice for hydraulic systems, pneumatic applications, and as protective sheathing for various hoses.

2. Medical and Pharmaceutical In medical applications, PVC braided tubing is often used for IV lines, medical device connections, and pharmaceutical transport. Its biocompatibility and ease of sterilization make it suitable for use in healthcare settings.

3. Agriculture Farmers and agricultural professionals use PVC braided tubing for irrigation and chemical application systems. Its ability to resist harsh chemicals makes it perfect for transporting fertilizers and pesticides.

4. Automotive The automotive industry employs this tubing for fuel lines, coolant systems, and oil transfer, where resilience and heat resistance are critical.

5. Aquarium and Hydroponics PVC braided tubing is popular in hobbyist applications such as aquariums and hydroponic systems, where water and nutrient movement is required. Its flexibility and clarity make it easy to use and monitor.

Benefits

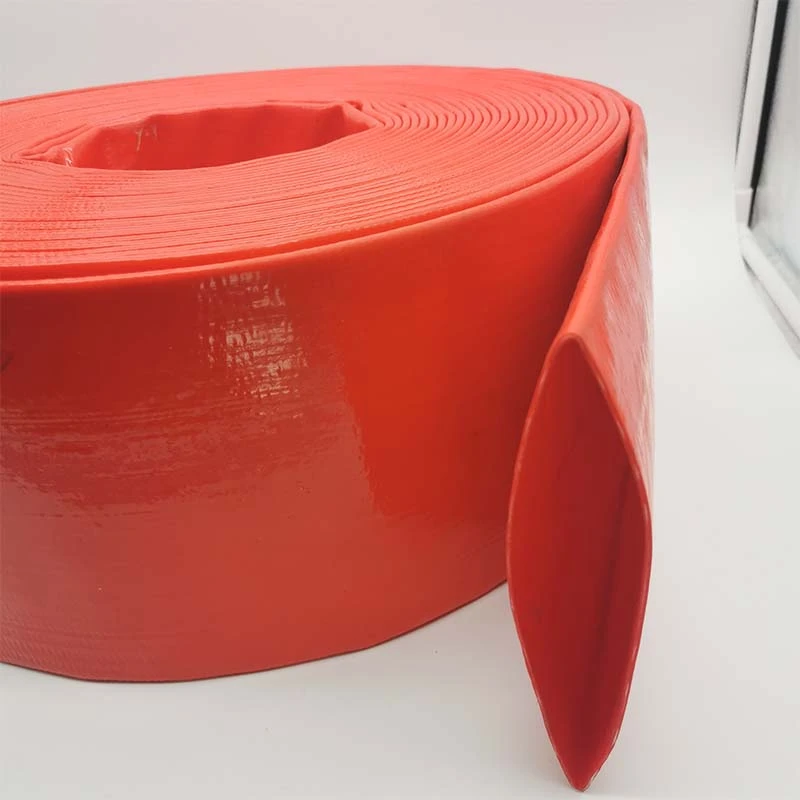

pvc braided tubing

The benefits of using PVC braided tubing are numerous

- Durability Thanks to its robust construction, this tubing is built to last, reducing the need for frequent replacements. - Flexibility The braided design allows for bending and maneuvering in tight spaces without kinking or damaging the tubing.

- Chemical Resistance PVC braided tubing can withstand various chemicals, making it suitable for a range of applications where exposure to harsh substances is common

.- Cost-Effectiveness Compared to other materials like rubber or metal tubing, PVC is often more affordable, providing a cost-effective solution for businesses and individuals alike.

- Safety PVC braided tubing is typically non-toxic and can meet various regulatory standards for safety, particularly in medical and food-related applications.

Considerations

When selecting PVC braided tubing for your needs, consider the following factors

- Diameter and Length Ensure that the tubing’s dimensions are appropriate for your specific application. Various sizes can accommodate different flow rates and pressure requirements.

- Pressure Rating Check the manufacturer’s specifications for the pressure rating to ensure that the tubing can handle the operational conditions you require.

- Chemical Compatibility If your application involves specific chemicals, verify that PVC braided tubing is compatible to avoid degradation and failure.

- Temperature Range Consider the temperature limits within which the tubing will operate to prevent any thermal issues.

Conclusion

PVC braided tubing is an exceptional choice for a wide range of applications due to its strength, flexibility, and resistance to various environmental factors. From industrial uses to healthcare, agriculture, and more, this versatile tubing has proven itself as a reliable solution. By understanding its characteristics, applications, and benefits, you can make an informed decision about how PVC braided tubing can meet your specific needs. Whether you’re a manufacturer, healthcare provider, or hobbyist, investing in quality PVC braided tubing can enhance efficiency and safety in your projects.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025