1 4 oxy acetylene hose

Understanding 1% Oxy-Acetylene Hose Applications, Features, and Safety Considerations

Oxy-acetylene welding, a widely used method for metal fabrication and cutting, relies heavily on the proper handling of gases through specialized hoses. Among the various components involved, the oxy-acetylene hose plays a crucial role in the efficiency and safety of the welding process. In this article, we will explore the characteristics of 1% 204% oxy-acetylene hoses, their applications, features, and essential safety considerations that are paramount in welding operations.

What is Oxy-Acetylene Welding?

Oxy-acetylene welding is a process that uses a flame produced by the combustion of oxygen and acetylene gas to melt and fuse metals. The mixture of these gases creates an extremely high-temperature flame, making it ideal for welding and cutting materials such as steel, aluminum, and wrought iron. The efficiency of this process largely depends on the quality and condition of the hoses used to deliver the gases.

Features of 1% 204% Oxy-Acetylene Hose

The term “1% 204%” refers to specific performance characteristics of the hose designed for oxy-acetylene applications. While the terminology may seem technical, it essentially signifies

1. Pressure Rating The 1% can indicate a hose’s compositional standard concerning its pressure rating. High-quality oxy-acetylene hoses are constructed to handle high pressure without bursting, which is crucial for safe operations.

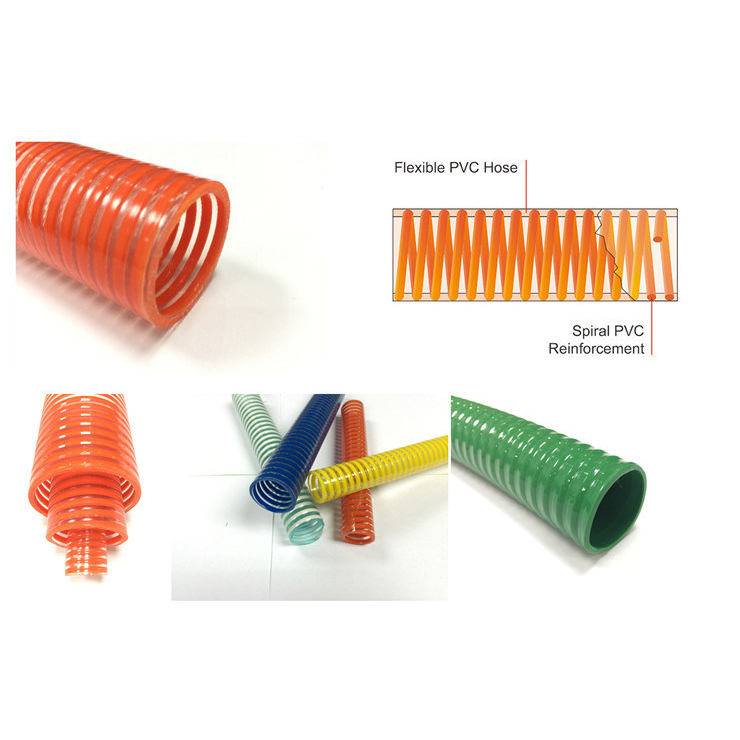

2. Flexible and Durable Materials Typically, these hoses are made from synthetic rubber or thermoplastic materials which provide flexibility and durability. This flexibility allows users to maneuver the hose easily in various environments, while the durability ensures long life even under extreme conditions.

3. Color Coding Oxy-acetylene hoses are usually color-coded for safety; acetylene hoses are often black, and oxygen hoses are green. This distinction minimizes the risk of accidental misconnection during setup.

4. Reinforcement Many hoses come with reinforced layers to prevent kinking and to maintain shape under pressure. This reinforcement also plays a significant role in protecting against abrasions and punctures.

5. Temperature Resistance These hoses are designed to withstand the high temperatures generated during welding, ensuring that they maintain integrity even with prolonged exposure to heat.

Applications

Oxy-acetylene hoses are utilized in numerous applications

1 4 oxy acetylene hose

1. Welding This is the most common application, where the oxy-acetylene process is employed to join metals in construction, automotive repair, and industrial fabrication.

2. Cutting Oxy-acetylene cutting is a common practice for slicing through thick metal plates, which is invaluable in metalworking industries.

3. Brazing and Soldering These hoses are also used for brazing and soldering tasks in plumbing and electrical work, where high-temperature flames are necessary to join various materials.

Safety Considerations

Regardless of their widespread use, oxy-acetylene hoses come with inherent risks. Ensuring the safety of users and work environments is paramount

1. Regular Inspection Hoses should be regularly checked for cracks, leaks, or signs of wear. Any damaged hoses should be replaced immediately to prevent accidents.

2. Proper Storage Hoses should be stored away from chemicals, heat sources, and direct sunlight to prolong their life and maintain safety.

3. Correct Connections Always ensure that the hoses are correctly connected to their respective regulators and that there are no cross-connections between oxygen and acetylene.

4. Use in Well-Ventilated Areas Since acetylene is flammable, using these hoses in well-ventilated areas is essential to prevent the accumulation of gas.

5. Training and Awareness Proper training for all personnel using oxy-acetylene equipment is crucial to minimize risks. Understanding the characteristics of the hoses and the hazards associated with their use can significantly enhance workplace safety.

Conclusion

The 1% 204% oxy-acetylene hose is a vital component in the welding industry, ensuring safe and efficient operation for welding, cutting, and brazing tasks. Through a combination of high pressure tolerance, flexibility, and durability, these hoses support a myriad of applications. However, recognizing their potential hazards and implementing rigorous safety measures is essential for ensuring a safe working environment. Every welder and technician must prioritize safety without compromising on the quality of their tools, and the oxy-acetylene hose stands at the forefront of that responsibility.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025