The Dynamic Landscape of PVC Hose Industry Players and Pricing

In the industrial and commercial sectors, PVC hoses have become essential components for various applications, ranging from fluid transfer to industrial processes. The entities involved in the production and supply of these hoses, such as PVC hose manufacturer, PVC hose factory, and PVC hose suppliers, play a crucial role in meeting market demands. Additionally, aspects like PVC hose pipe price and PVC hose price significantly influence purchasing decisions and the overall industry dynamics.

The Role of PVC Hose Manufacturers in Product Excellence

In the competitive world of PVC hose production, PVC hose manufacturer entities strive to create high - quality products that meet diverse customer needs. These manufacturers invest in advanced production technologies and quality control measures. For instance, a leading PVC hose manufacturer might use state - of - the - art extrusion machines to ensure consistent wall thickness and smooth inner surfaces in their hoses. By carefully selecting raw materials, such as high - grade PVC compounds, they can produce hoses that are resistant to chemicals, abrasion, and extreme temperatures. In industries like agriculture, where hoses are used for irrigation purposes, a reliable PVC hose manufacturer can provide hoses that can withstand the rigors of outdoor use, ensuring long - lasting performance and efficient water transfer.

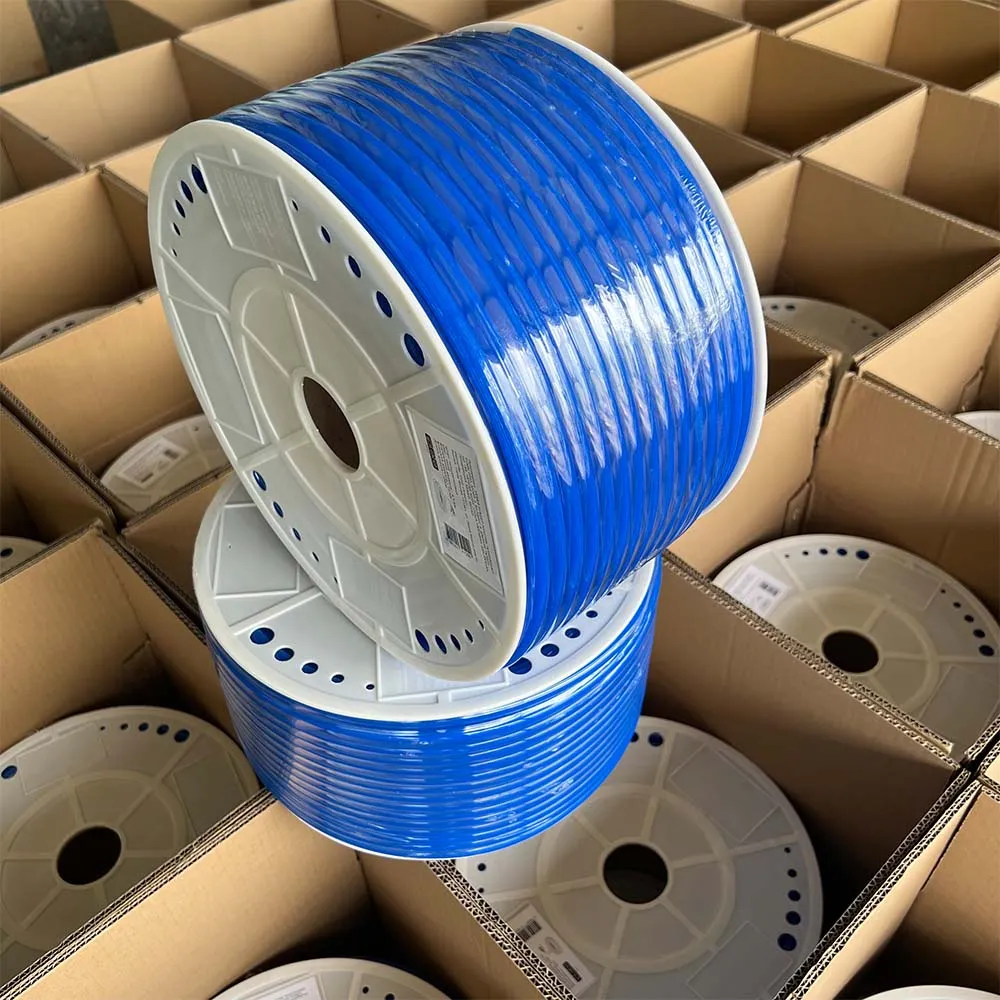

Inside the Operations of PVC Hose Factories

PVC hose factory facilities are the heart of the production process. These factories are equipped with specialized machinery and skilled labor to transform raw materials into finished PVC hoses. A well - organized PVC hose factory follows strict production protocols to maintain product quality. They may have dedicated departments for material handling, extrusion, cutting, and testing. For example, after the extrusion process, hoses in a PVC hose factory are subjected to rigorous pressure tests to ensure they can handle the intended working pressures without bursting or leaking. In addition, the factory's layout and workflow are designed to optimize production efficiency, reducing production time and costs while still delivering hoses that meet or exceed industry standards.

The Vital Link: PVC Hose Suppliers in the Market

PVC hose suppliers act as the vital link between manufacturers and end - users. They source hoses from various PVC hose manufacturer and PVC hose factory units and make them available to customers across different industries. These suppliers offer a wide range of PVC hoses, catering to different applications and specifications. For instance, a PVC hose supplier might provide hoses for automotive cooling systems, which require hoses with excellent heat resistance and flexibility. They also offer value - added services such as inventory management, timely delivery, and technical support. In construction projects, where the need for PVC hoses for concrete pumping or water supply is urgent, reliable PVC hose suppliers can ensure that the required hoses are delivered promptly, keeping the project on schedule.

Deciphering the Factors Behind PVC Hose Pipe Price

The PVC hose pipe price is influenced by multiple factors. Raw material costs play a significant role, as the price of PVC resin and other additives can fluctuate based on market conditions. For example, if there is a shortage of PVC resin in the market, the cost of producing PVC hoses will increase, leading to a rise in the PVC hose pipe price. Manufacturing processes also contribute to the price. Hoses with complex designs or additional features, such as reinforced layers or special coatings, will generally be more expensive due to the higher production costs involved. Additionally, factors like transportation costs, demand and supply dynamics, and the reputation of the PVC hose manufacturer or PVC hose supplier can impact the final price of the hoses in the market.

Understanding the Variations in PVC Hose Price

The PVC hose price can vary widely depending on several aspects. Hose diameter and length are important determinants, as larger and longer hoses typically require more material and thus cost more. The quality of the hose also affects the price. High - quality hoses that offer better performance, durability, and resistance to various elements will command a higher price compared to lower - quality alternatives. Brand reputation also plays a role. Hoses from well - known PVC hose manufacturer or supplied by reputable PVC hose suppliers may be priced higher due to the trust and reliability associated with their products. Moreover, market competition can lead to price variations, with different suppliers offering competitive prices to attract customers.

Insights and Considerations for the PVC Hose Industry

Selecting the Right PVC Hose Manufacturer or Supplier

When choosing a PVC hose manufacturer or PVC hose supplier, several factors should be considered. Quality should be a top priority. Look for manufacturers or suppliers who have a proven track record of producing high - quality hoses and adhere to industry standards. Consider their product range to ensure they can meet your specific requirements. Customer reviews and testimonials can provide valuable insights into their reputation and the quality of their services. Additionally, factor in aspects such as their production capacity, delivery times, and pricing to make an informed decision that best suits your needs.

Cost - Effective Strategies for Purchasing PVC Hoses

To obtain PVC hoses at a cost - effective price, consider bulk purchasing. Buying in larger quantities from a PVC hose supplier or directly from a PVC hose manufacturer can often result in discounted prices. Compare prices from multiple suppliers to find the best deal, but also ensure that the quality of the hoses is not compromised. Look for promotions or special offers that suppliers may provide. Additionally, consider the total cost of ownership, including factors like maintenance and replacement costs, when evaluating the price of PVC hoses. A slightly higher - priced hose with better durability may be more cost - effective in the long run compared to a cheaper, less durable option.

Future Trends Impacting PVC Hose Manufacturers, Factories, and Suppliers

The PVC hose industry is constantly evolving, and several trends are likely to impact PVC hose manufacturer, PVC hose factory, and PVC hose suppliers in the future. The increasing demand for sustainable and eco - friendly products may lead to the development of PVC hoses made from recycled materials or with reduced environmental impact. Technological advancements, such as the use of smart materials or improved manufacturing processes, could result in hoses with enhanced performance and functionality. Additionally, changes in industry regulations and standards may require manufacturers and suppliers to adapt their production methods and product offerings to remain compliant and competitive in the market.

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionاخبارJul.16,2025

-

The Crucial Role and Varieties of LPG Gas HosesاخبارJul.16,2025

-

PVC Flexible Hoses in Industrial Applications: A Comprehensive OverviewاخبارJul.16,2025

-

High - Pressure LPG Hoses - Ensuring Safety and Efficiency in Fuel TransferاخبارJul.16,2025

-

Essential Tools for Welding Operations: Oxy - Acetylene HosesاخبارJul.16,2025

-

Essential Connections - LP Gas Hoses and Their VariantsاخبارJul.16,2025