جولای . 29, 2025 11:00

Back to list

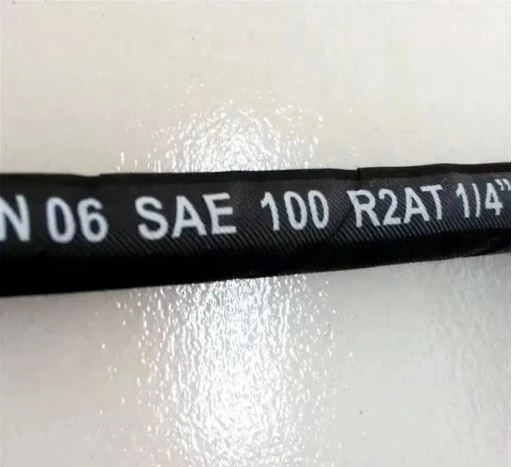

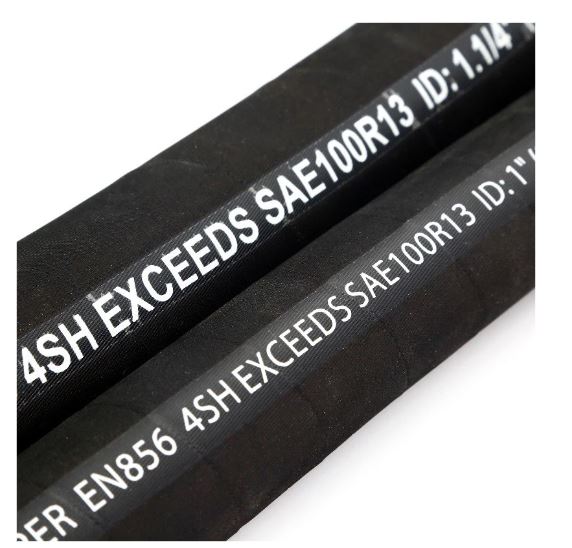

High Pressure SAE 100 R2 Hydraulic Hose – Durable & Reliable Solution

SAE 100 R2 is a high-pressure, double-wire-braided hydraulic hose widely adopted in petrochemical, metallurgy, machinery, mining, and construction industries. This comprehensive guide explores its industry trends, technical specifications, manufacturing process, advantages, supplier comparison, customization, and real-world use cases. For more product info, visit the official page: SAE 100 R2 Product Details.

Industry Trends: SAE 100 R2 Market and Technology Direction

- The 2023 global hydraulic hose market was valued at USD 1.80 billion, with SAE 100 R2 accounting for nearly 18% of the segment (Source: Technavio, 2024).

- Predicted CAGR (2024-2029) for double-wire-braided hoses: 6.5%, fueled by industrial automation and increased demand in offshore & mining sectors.

- Technological focus: higher pressure ratings (up to 6000 psi), enhanced abrasion & ozone resistance, and eco-friendly raw materials (ISO 14001 compliance).

Technical Data: SAE 100 R2 Specifications & Comparison

| Parameter | SAE 100 R2 | SAE 100 R1 | EN 853 2SN | EN 857 2SC |

|---|---|---|---|---|

| Construction | Double steel wire braid | Single steel wire braid | Double steel wire braid | Double steel wire braid (compact) |

| Inner tube material | Oil-resistant synthetic rubber | Oil-resistant synthetic rubber | Oil-resistant synthetic rubber | Oil-resistant synthetic rubber |

| Reinforcement | 2 steel wire braids | 1 steel wire braid | 2 steel wire braids | 2 steel wire braids |

| Working Pressure | up to 6000 psi (42.0 MPa) | up to 3625 psi (25.0 MPa) | up to 5800 psi (40.0 MPa) | up to 6000 psi (42.0 MPa) |

| Burst Pressure | ≥16000 psi (112.0 MPa) | ≥14500 psi (100.0 MPa) | ≥17400 psi (120 MPa) | ≥18000 psi (125 MPa) |

| Temperature Range | -40°C to +100°C (-40°F to +212°F) |

-40°C to +100°C | -40°C to +100°C | -40°C to +100°C |

| Bend Radius | from 100 mm (size dependent) | from 90 mm | from 115 mm | from 90 mm (compact) |

| Standard Compliance | SAE J517, ISO 1436 | SAE J517 | EN 853 | EN 857 |

SAE 100 R2 outperforms single-wire alternatives in pressure capability, service life, and safety margin, making it optimal for high-stress hydraulic systems.

Working Pressure

Burst Pressure

Manufacturing Process: How is SAE 100 R2 Made?

The SAE 100 R2 hydraulic hose is manufactured through an advanced multi-step process designed for high durability and precise standards. The main stages involve:

- Material Selection:

- High-grade NBR synthetic rubber (inner tube) offers excellent oil resistance, meeting ISO 18752 standards.

- 2x high-tensile steel wire braids (reinforcement), providing strength and flexibility.

- Weather-resistant synthetic rubber (cover), tested for ozone, abrasion, and flame resistance.

- Inner Tube Extrusion:

- Precision extruded for smooth oil flow and minimal permeability.

- Wire Braiding (Reinforcement):

- Two braiding passes by automated CNC machinery ensure tensile uniformity (braid angle control & adhesion test as per SAE J343).

- Cover Extrusion & Bonding:

- Composite cover applied with increased adhesion (180°C vulcanization minimizes delamination risk).

- Curing & Pressure Testing:

- Each hose batch is cured at 150–180°C, then 100% proof tested at 2x working pressure per ISO 1402 and SAE J517.

- Precision Cutting & CNC End-Finishing:

- Automated CNC cutting for length tolerance ≤0.5%, custom OEM fitting installation.

- Quality Inspection & Certification:

- Random sample burst test, abrasion test (per ISO 6945), and compliance labeling.

Vulcanization

Wire Braiding

Pressure Test

Key certifications: ISO 9001, ISO 14001, SAE J517 ; major OEMs require burst tests certified to ANSI/SAE 45.2 and EN 853.

Quality Control in Practice: Each SAE 100 R2 batch undergoes hydrostatic testing and dynamic impulse test (>200,000 cycles) to guarantee over 2x safer than minimum burst requirements, ensuring extended service life in harsh environments.

Quality Control in Practice: Each SAE 100 R2 batch undergoes hydrostatic testing and dynamic impulse test (>200,000 cycles) to guarantee over 2x safer than minimum burst requirements, ensuring extended service life in harsh environments.Reference: Hydraulic Hose Testing Protocols, Fluid Power Journal, Vol.30, 2022.

Technical Strengths: Why Choose SAE 100 R2?

- Superior Pressure & Safety Margin: Handles up to 6000psi with burst ratios ≥4:1 for critical operations.

- Longevity: Expected lifespan >50,000 cycles even under full load (field data: coal mining OEMs, 2021).

- Resistance: Outstanding oil, abrasion, flame, weather, and ozone resistance. Surface uses patented technology for anti-cracking & anti-aging.

- Flexibility: Bend radius as small as 100mm increases routing versatility especially in compact or mobile equipment.

- Compliance: Exceeds requirements of SAE J517, ISO 1436, and performs above EN 853 for impulse and pressure—it is a preferred global standard in hydraulics engineering.

Application Scenarios & Real Use Cases of SAE 100 R2

- Petrochemical Plants: Used in high-pressure oil/gas transfer lines up to 420 bar in refinery and offshore platforms for reliable operation under aggressive media.

- Metallurgical Industry: Critical for hydraulic presses, continuous casting systems, and furnace doors due to thermal/abrasion resilience.

- Civil Construction: Found on excavators, cranes, tunnel boring machines; high impulse life reduces downtime.

- Water Hydraulic Systems: For high-pressure cleaning and municipal water supply using non-contaminating covers, certified by WRAS.

- Renewable Energy: In wind turbines and solar trackers for actuator hydraulics where flexibility/ruggedness are crucial (installation in sub-zero and hot climates).

Feedback: “After switching to SAE 100 R2 for our mobile cranes, annual hydraulic pipe failures dropped by 77%. Reliability and onsite safety noticeably improved.”

— Customer, Energy Construction Ltd, UK (2023)

— Customer, Energy Construction Ltd, UK (2023)

Real-world Example: A leading coal mine OEM selected SAE 100 R2 for its shuttle cars, reporting zero hose bursts for 20 months—previously, bursts occurred every 6 months.

Supplier Comparison: How Does SAE 100 R2 Manufacturer Stack Up?

| Company | Certifications | Pressure Ratings | Sample Lead Time | Key Client |

|---|---|---|---|---|

| Kebing Hose (SAE 100 R2) | ISO 9001/14001, SAE J517, WRAS | Up to 6000 psi | 5 days | SANY, Sandvik |

| Parker Hannifin | ISO 18752, SAE J343 | Up to 5800 psi | 8 days | Caterpillar |

| Gates Corporation | SAE, ISO, DNV | Up to 6100 psi | 7 days | Komatsu |

| Manuli Hydraulics | ISO, API 7K | Up to 6500 psi | 10 days | Atlas Copco |

Authority Highlight: Kebing Hose, with 25+ years of manufacturing experience and ISO/SAE/WRAS certifications, partners with major OEMs globally and has received recurring positive audits from Bureau Veritas and SGS. For more, product page.

Authority Highlight: Kebing Hose, with 25+ years of manufacturing experience and ISO/SAE/WRAS certifications, partners with major OEMs globally and has received recurring positive audits from Bureau Veritas and SGS. For more, product page.

Customization & Delivery: Tailored SAE 100 R2 for Special Requirements

- Customization Options:

- Non-standard lengths (up to 80m per reel, or custom cut-to-length)

- Special covers (flame-retardant, MSHA, anti-static, color coding, FDA potable water)

- CNC crimped fittings: BSP, NPT, JIC, DIN, SAE, or proprietary connections

- UL, FDA, API or marine certifications for critical fluid transfer/hazardous applications

- Ultra-low temperature design (to -55°C), UV-stabilized covers for desert or arctic installation

- Delivery & Service:

- Standard dispatch within 7–12 days after order confirmation (priority for OEMs/urgent projects)

- All hoses provided with traceable batch & test certificates

- Lifetime technical support, 24/7 online service, and optional on-site survey/training

FAQ: SAE 100 R2 Technical FAQ

1. What is the core material for SAE 100 R2 hoses and why?

Nitrile butadiene rubber (NBR) is chosen for its oil resistance and thermal stability; it complies with ISO 18752 and guarantees minimum oil swelling.

2. What international standards apply to SAE 100 R2 hoses?

SAE J517, ISO 1436, and EN 853 2SN are main standards. Compliance means the hose is suitable for global (EU/North America/Asia) OEM use.

3. What’s the typical burst pressure vs working pressure?

The hose is rated at up to 6000 psi working pressure and must withstand burst pressures of at least 4x working (typically 16,000–18,000 psi), verified per SAE/ISO burst tests.

4. How is the steel wire reinforcement applied?

Double steel wire is braided using precision CNC equipment to control braid angle and tension, boosting both flexibility and crush resistance.

5. What installation standards are recommended?

Hose routing should comply with ISO/TR 17165-2 and avoid sharp bends below the minimum bend radius. Assembly with certified crimped fittings only.

6. What is the typical temperature range for SAE 100 R2?

-40°C to +100°C (oil); for water/emulsion: -40°C to +80°C. Extreme versions available by request.

7. What about warranty and after-sales?

Standard warranty: 24 months (or 120,000 cycles), with field failure investigation, replacement, and 24/7 support.

Trust & Support: Certificates, After-Sales & Documentation

- Certification: All SAE 100 R2 hoses are 100% batch-tested, each item labeled with traceable QR code, and supplied with ISO/SAE/WRAS certificates and test reports upon delivery.

- Warranty: 24 months minimum, with immediate replacement for certified field failures. Extended warranty options for OEM partners.

- Support: 24/7 technical team (remote and onsite). Full installation guidance, maintenance training (downloadable manuals, video, VR demo).

- Documentation: Pressure, impulse, and abrasion test data is archived for 10 years, accessible for regulatory/safety audits.

For application consulting, customization, formal quotation or technical support, visit Official Page

References & Further Reading

Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE