suction hose vs discharge hose

Understanding the Differences Between Suction Hose and Discharge Hose

When it comes to fluid transfer systems, the type of hose you choose plays a pivotal role in the efficiency and effectiveness of your operations. Two terms frequently encountered in this context are suction hose and discharge hose. While they may appear similar at first glance, their specific functions, construction, and applications set them apart. This article aims to delve into the key differences between suction and discharge hoses, how they are used, and their respective benefits.

What is Suction Hose?

Suction hoses are designed to transport fluids via a negative pressure system. Their primary function is to draw liquids from a source, such as a tank, well, or pond. In this system, fluid moves towards the hose due to the vacuum created by a pump. Suction hoses typically need to withstand low pressure but should be robust enough to handle the external atmospheric pressure when the fluid is being drawn in.

Construction and Characteristics

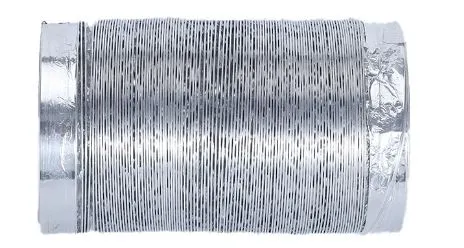

Suction hoses are often constructed from materials like PVC, rubber, or polyurethane. They are flexible and durable, allowing them to bend around corners and navigate tight spaces without kinking. Additionally, suction hoses usually come with some form of reinforcement, such as spiral wires or braiding, to maintain their shape and allow for proper flexibility under suction conditions.

The inner diameter of a suction hose can vary widely depending on its intended use, and it often features a smooth bore to minimize turbulence and enhance flow efficiency. Suction hoses also typically have a thicker wall compared to discharge hoses to prevent collapsing under atmospheric pressure.

What is Discharge Hose?

In contrast, discharge hoses are designed to transport fluids away from a source after they have been pumped. These hoses handle positive pressure, as liquid is expelled from the hose towards its destination, such as a storage tank or an irrigation system. Discharge hoses are crucial in applications where precise distributions of fluids are necessary.

suction hose vs discharge hose

Construction and Characteristics

Similar to suction hoses, discharge hoses are usually made from materials like rubber, PVC, or thermoplastic. However, their construction may differ in terms of wall thickness and reinforcement, as they need to withstand higher pressures due to the force pushing the fluid out. Discharge hoses may have a wider diameter to facilitate a higher flow rate, and just like suction hoses, they require flexibility to navigate various terrains.

Discharge hoses can come with fittings or couplings on one or both ends, which facilitate easy connection to pumps or other equipment. The hose's smooth interior is essential for reducing friction loss and ensuring an efficient transfer of fluid.

Key Differences Between Suction and Discharge Hoses

Pressure Handling The most crucial difference lies in the pressure management suction hoses operate under negative pressure, whereas discharge hoses are designed for positive pressure.

Material and Construction While both types may be manufactured from similar materials, suction hoses generally have thicker walls to resist the risk of collapsing, whereas discharge hoses might be reinforced to manage higher internal pressures.

Application Focus Suction hoses are deployed in applications related to drawing fluids in, while discharge hoses are employed when expelling liquids from a system. For instance, a suction hose might be used in a firefighting application to draw water from a nearby source, while a discharge hose could transport that water to a fire engine or irrigation system.

Conclusion

In summary, understanding the distinctions between suction and discharge hoses is fundamental to effective fluid management in various industries. Choosing the right hose not only ensures efficiency but also enhances safety by reducing the likelihood of system failures or leaks. Whether you are operating a construction site, managing agricultural irrigation, or involved in industrial processes, knowing the appropriate application for suction versus discharge hoses can make a significant difference. Always consider the parameters of your specific project and consult with experts if necessary to select the right hose for your needs.

-

Unrivaled Performance and Applications of PU Pneumatic Hoses and TubesNewsJun.11,2025

-

The Transparent World of Industrial Tubing and Hosing SolutionsNewsJun.11,2025

-

The Intricate World of Pneumatic Conduits: Tubes and HosesNewsJun.11,2025

-

The Dynamic Landscape of Pneumatic Conduits: Unraveling Key ComponentsNewsJun.11,2025

-

The Diverse Applications and Significance of Transparent PVC TubingNewsJun.11,2025

-

High - Pressure Pneumatic Tubing and Systems: An In - Depth LookNewsJun.11,2025