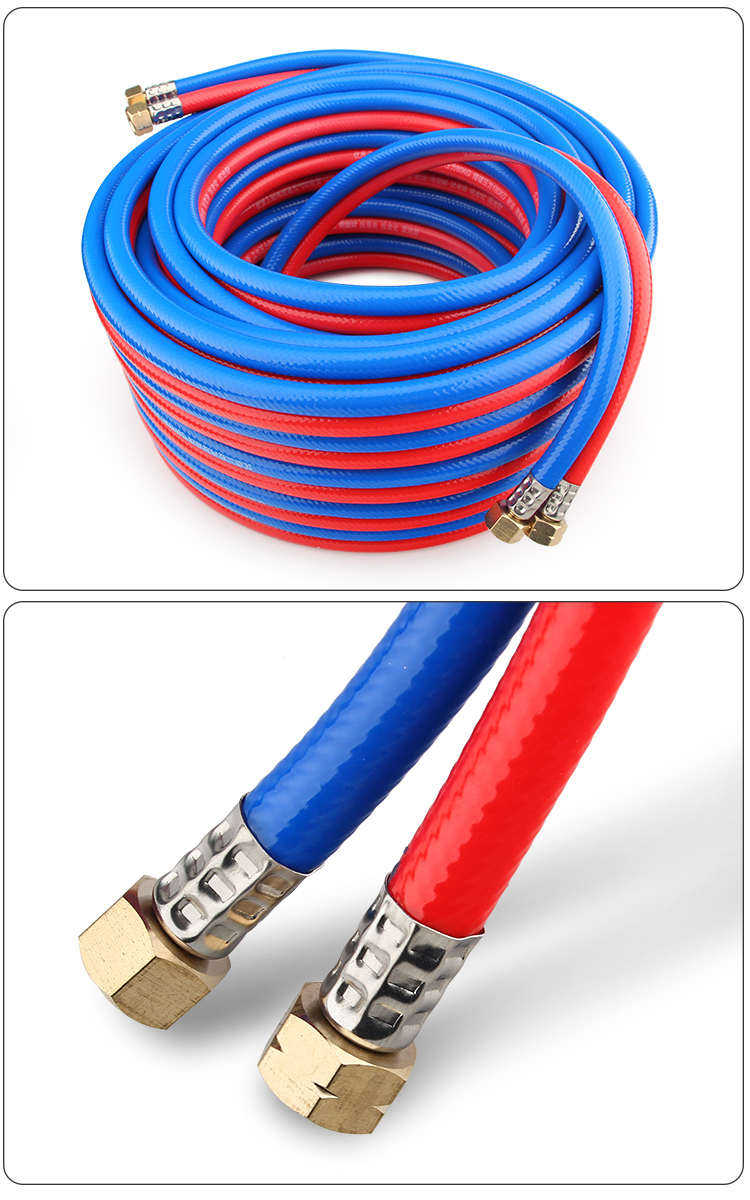

oxy acetylene twin hose

The Essential Role of Oxy-Acetylene Twin Hoses in Welding

Oxy-acetylene welding is a widely used process that combines oxygen and acetylene gases to create a flame capable of welding, cutting, and brazing metals. Central to this process is the oxy-acetylene twin hose, a vital component that ensures the efficient and safe transport of these gases from their respective cylinders to the welding torch.

Structure and Function

An oxy-acetylene twin hose is designed as a two-in-one system, with one hose specifically for oxygen (usually colored green) and the other for acetylene (typically colored red). These hoses are constructed from durable materials such as rubber and are reinforced with multiple layers to withstand high pressures. The design prevents the gases from mixing before they reach the torch, a critical safety feature. Most twin hoses have a maximum working pressure of around 300 psi, making them suitable for various welding tasks.

The separation of the hoses allows welders to precisely control the ratio of oxygen to acetylene, which is crucial for achieving the desired flame properties. For example, a carburizing flame, used for certain types of welding, requires a higher acetylene-to-oxygen ratio, while a neutral flame, ideal for most welding applications, needs equal parts of both gases. The ability to fine-tune these ratios through the twin hose system is essential for the quality and strength of the weld.

Safety Considerations

Safety is paramount when working with oxy-acetylene equipment. The twin hose system reduces the risks associated with gas leaks and accidental ignition. In addition, many hoses are equipped with flashback arrestors, devices that prevent the flame from traveling back into the hose and potentially causing an explosion. Regular inspection of hoses for wear and tear is crucial; cracks or leaks can lead to dangerous situations.

oxy acetylene twin hose

Proper handling and storage of the hoses also play a role in safety. When not in use, hoses should be coiled neatly and stored away from heat sources. It is advisable to avoid kinking or pinching the hoses, as this can compromise their integrity.

Applications in Welding and Metalworking

Oxy-acetylene welding, facilitated by the twin hose system, is applicable across a wide range of industries, from automotive repair to metal fabrication. Its versatility allows for not only welding but also cutting metals effectively. This method is particularly advantageous in situations where portability is necessary, as oxy-acetylene setups can be used in remote locations without the need for extensive electrical infrastructure.

In addition, the oxy-acetylene flame can reach temperatures of approximately 3,500 degrees Fahrenheit (about 1,926 degrees Celsius), making it effective for joining thicker materials that other welding processes may struggle with. This ability to produce high temperatures translates to better penetration and stronger welds.

Conclusion

The oxy-acetylene twin hose system is an indispensable component of welding and metalworking operations. Its robust design, coupled with the safety features it offers, enables welders to work efficiently and effectively. As industries continue to innovate and evolve, the importance of reliable equipment, including the twin hose, will remain critical to achieving high-quality results in metal fabrication and repair. Whether used in workshops or in the field, the oxy-acetylene twin hose embodies the essence of practical engineering, making it a cornerstone in the realm of welding.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025