Φεβ . 07, 2025 05:54

Back to list

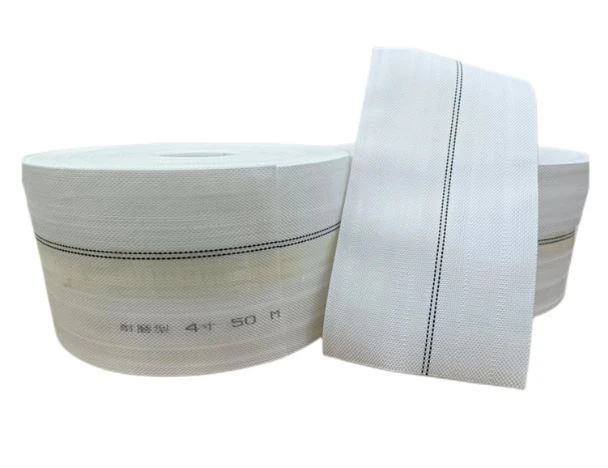

TPU Layflat Hose

When choosing the right layflat hose for a particular application, navigating the available sizes effectively can significantly impact performance and efficiency. Layflat hoses, popular in sectors such as agriculture, construction, and firefighting, provide a flexible solution for transporting liquids. Understanding the intricacies of layflat hose sizes helps in selecting the ideal hose that aligns with specific needs, while considering factors such as flow requirements, pressure ratings, and compatibility with existing systems.

The length of the hose is another vital consideration. While hoses can be purchased in varying lengths depending on the application, choosing a standard length that can be easily maneuvered without excessive drag and weight is often practical. Generally, layflat hoses are available in lengths ranging from 25 feet to 300 feet, with longer lengths being ideal for large-scale agricultural or industrial projects where reaching distant water sources is necessary. An important consideration when evaluating layflat hose sizes and selections is the hose’s versatility and adaptability to various fittings and connections, ensuring it supports multiple applications. This capability enhances the operational flexibility and increases the utility of the investment. Expert manufacturers and suppliers can often provide guidance and recommendations that consider all these factors holistically. Consulting industry professionals who understand the intricacies of layflat hose applications, such as Beverley Rubber Hose Supply or FlexTech hoses, ensures that the selection not only meets but exceeds the expected use-case conditions and performance metrics. Emphasizing factors like ease of handling, strength, and reliability can significantly boost product credibility and instill customer trust. Transparency in testing certifications and adherence to industry standards such as ISO 8031 and ISO 4649 for flexibility and abrasion resistance respectively, lend authority and establish a brand's reputation for quality and dependability. In summary, the selection process for layflat hose sizes revolves around understanding the balance between efficient fluid conveyance, pressure tolerance, material composition, and environmental demands. Choosing the right hose involves not only leveraging technical specifications but also applying real-world insights to satisfy application-specific challenges. By mastering these variables, one can ensure long-term performance, reliability, and overall satisfaction with their layflat hose investment.

The length of the hose is another vital consideration. While hoses can be purchased in varying lengths depending on the application, choosing a standard length that can be easily maneuvered without excessive drag and weight is often practical. Generally, layflat hoses are available in lengths ranging from 25 feet to 300 feet, with longer lengths being ideal for large-scale agricultural or industrial projects where reaching distant water sources is necessary. An important consideration when evaluating layflat hose sizes and selections is the hose’s versatility and adaptability to various fittings and connections, ensuring it supports multiple applications. This capability enhances the operational flexibility and increases the utility of the investment. Expert manufacturers and suppliers can often provide guidance and recommendations that consider all these factors holistically. Consulting industry professionals who understand the intricacies of layflat hose applications, such as Beverley Rubber Hose Supply or FlexTech hoses, ensures that the selection not only meets but exceeds the expected use-case conditions and performance metrics. Emphasizing factors like ease of handling, strength, and reliability can significantly boost product credibility and instill customer trust. Transparency in testing certifications and adherence to industry standards such as ISO 8031 and ISO 4649 for flexibility and abrasion resistance respectively, lend authority and establish a brand's reputation for quality and dependability. In summary, the selection process for layflat hose sizes revolves around understanding the balance between efficient fluid conveyance, pressure tolerance, material composition, and environmental demands. Choosing the right hose involves not only leveraging technical specifications but also applying real-world insights to satisfy application-specific challenges. By mastering these variables, one can ensure long-term performance, reliability, and overall satisfaction with their layflat hose investment.

Next:

Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE