Versatile Air Tubing Solutions for Efficient Fluid Transport and Connectivity Options

Flexible Pneumatic Tubing An Essential Component in Modern Automation

In today’s rapidly advancing industrial landscape, the efficiency and effectiveness of automated systems have become paramount. One of the key components facilitating this progress is flexible pneumatic tubing. These tubes play a crucial role in the transmission of compressed air, which is necessary for powering various pneumatic tools and systems.

Flexible pneumatic tubing comes in various materials, including polyurethane, nylon, and polyamide. Each type offers distinct advantages, catering to different application requirements. For instance, polyurethane tubing is favored for its excellent flexibility and resistance to abrasions, making it ideal for applications where tight bends and complex routing are necessary. In contrast, nylon tubing provides enhanced durability and is often used in environments where increased rigidity is required.

One of the primary advantages of using flexible pneumatic tubing is its lightweight nature. This property minimizes the overall weight of pneumatic systems, contributing to improved energy efficiency and reduced wear on components. Moreover, the flexibility of these tubes allows for easy installation and routing in tight spaces, which is often a challenge in modern machinery designs.

flexible pneumatic tubing

Another critical aspect of flexible pneumatic tubing is its capacity to withstand a wide range of operating conditions

. Many types of tubing can endure high pressures, temperature fluctuations, and exposure to chemicals without compromising performance. This resilience ensures reliability and reduces the frequency of replacements, ultimately lowering maintenance costs.In addition, the adaptability of flexible pneumatic tubing makes it suitable for various applications, from simple pneumatic circuits to more complex systems found in robotics and packaging machinery. Industries such as automotive, aerospace, and manufacturing heavily rely on these tubes to enhance operational productivity and maintain a competitive edge in the market.

As manufacturers continue to innovate and develop new technologies, the demand for high-quality flexible pneumatic tubing is expected to increase. Advances in materials science and engineering are paving the way for even more robust and efficient tubing options that can withstand the rigors of modern industrial applications.

In conclusion, flexible pneumatic tubing represents a vital element in the functionality and efficiency of pneumatic systems. Its lightweight, durable, and adaptable nature makes it indispensable for a wide range of industrial applications. As automation continues to evolve, the role of flexible pneumatic tubing will only grow more prominent, driving innovation and excellence in various sectors.

-

Strong suction and flexibility: The versatile application of PVC suction hosesNewsAug.05,2025

-

Steel wire reinforcement, tough protection: The road to upgrading the strength of Wire Reinforced PVC HoseNewsAug.05,2025

-

Resilience and Flexibility Coexist: A New Industrial Perspective for Pvc Air HosesNewsAug.05,2025

-

Pulse of Efficient Transmission: The Excellent Performance and Multiple Applications of PU Pneumatic HoseNewsAug.05,2025

-

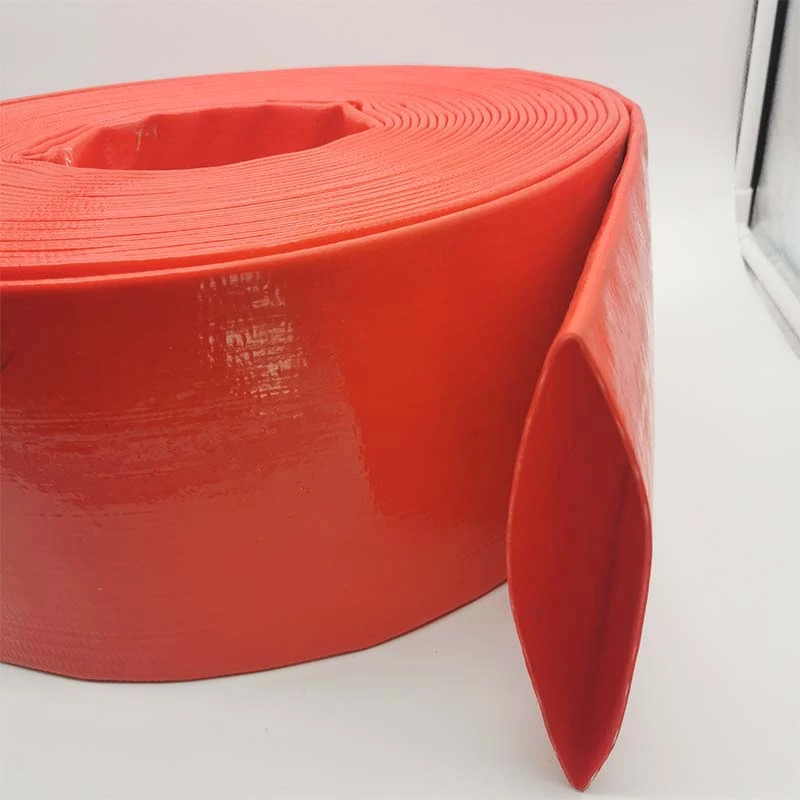

Enduring Pressure: The Industrial Mission of High Pressure Lay Flat HoseNewsAug.05,2025

-

Durable Water Conveyance: The Practical Value and Technical Charm of PVC WATER HOSESNewsAug.05,2025