Durable Corrugated PVC Hose - Flexible Suction Tubing

Understanding corrugated pvc hose in Industrial Applications

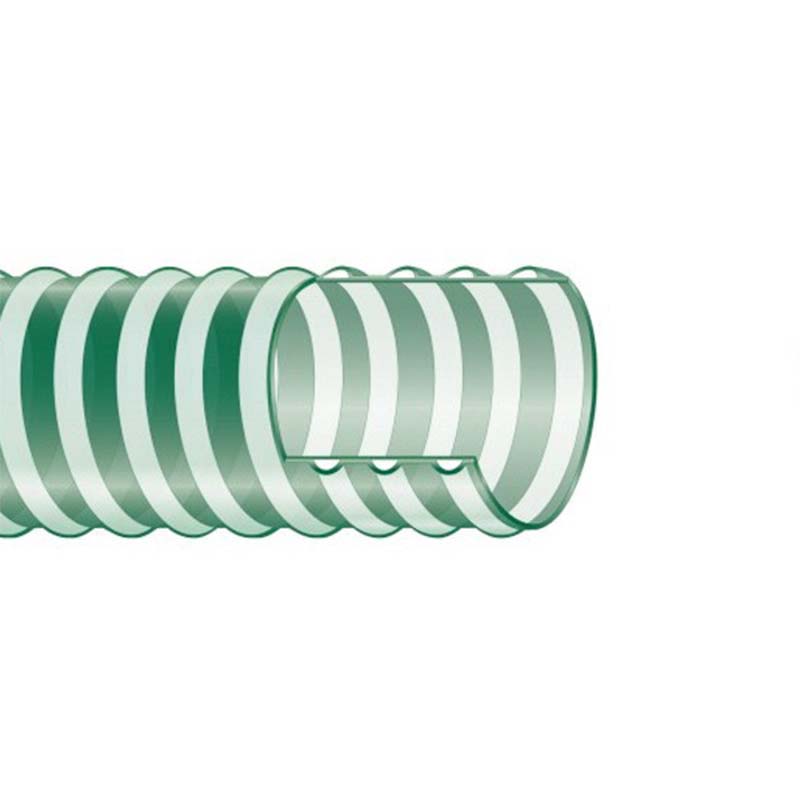

In diverse industrial sectors, the efficient and reliable transfer of fluids, slurries, and granular materials is paramount. This necessitates robust, flexible, and chemically resistant conduits. Among the myriad options, corrugated pvc hose stands out as a superior solution due to its unique design and material properties. Specifically engineered for suction and discharge applications, this type of hose offers exceptional flexibility, durability, and resistance to abrasion, making it indispensable across agriculture, construction, mining, and waste management. It effectively bridges the gap where rigid piping is impractical, providing a versatile alternative for various demanding environments.

Our flagship product, the PVC CORRUGATED SUCTION HOSE, exemplifies the peak of design and manufacturing precision in this category. It's crafted to deliver consistent performance even under challenging operational conditions, ensuring operational continuity and reducing maintenance downtime. This hose is particularly valued for its lightweight nature combined with significant strength, making handling and installation notably easier than heavier alternatives. Its transparency, often a key feature, allows for visual monitoring of flow, a crucial advantage in many fluid transfer processes, enhancing both safety and efficiency for operators.

The Advanced Manufacturing Process: Crafting Superior PVC Corrugated Hoses

The production of high-quality corrugated pvc tubing involves a sophisticated extrusion process that ensures the hose's integral strength, flexibility, and longevity. It begins with selecting premium-grade PVC resin compounds, often reinforced with plasticizers and UV stabilizers to enhance durability and environmental resistance. These compounds are meticulously blended and then fed into specialized extruders. Within the extruder, the material is heated and forced through a die, forming the continuous tubular shape.

A critical step for creating the distinct corrugated profile is the use of forming dies or molds immediately after extrusion. This gives the hose its characteristic ridges, which are crucial for its flexibility and resistance to kinking and crushing. Post-extrusion, the hose undergoes a precise cooling process to set its shape and material properties. Rigorous quality control checks are integrated at every stage, from raw material inspection to final product testing. This includes adherence to international standards such as ISO 9001 for quality management systems, ASTM standards for material properties, and sometimes even specific certifications like FDA compliance for food-grade applications, ensuring that each length of pvc corrugated flexible pipe meets stringent performance criteria.

Technical Parameters: Decoding the Performance of PVC Corrugated Suction Hose

Understanding the technical specifications of a pvc flexible suction hose is vital for selecting the right product for specific industrial demands. These parameters define the hose's capacity, durability, and suitability for various operating conditions. Our PVC CORRUGATED SUCTION HOSE is engineered to offer exceptional performance across a broad spectrum of applications, from agricultural irrigation to industrial waste removal.

| Parameter | Typical Range / Value | Description / Significance |

|---|---|---|

| Internal Diameter (ID) | 19mm (3/4") to 254mm (10") | Determines flow rate capacity. Wider IDs for higher volume transfer. |

| Working Pressure | 3-10 Bar (45-145 PSI) | Maximum continuous pressure the hose can withstand. Critical for safety. |

| Burst Pressure | 9-30 Bar (135-435 PSI) | The pressure at which the hose is expected to fail. Safety margin is typically 3:1. |

| Temperature Range | -10°C to +60°C (14°F to 140°F) | Operating temperature limits. Exceeding this can degrade material. |

| Bend Radius | Typically 1.5-2.5 x ID | Minimum radius without kinking. Essential for flexible installations. |

| Vacuum Rating | -0.8 to -0.9 Bar (24-27 inHg) | Ability to withstand negative pressure without collapsing, crucial for suction. |

| Material | PVC with rigid PVC helix | Ensures flexibility, durability, and resistance to crushing and abrasion. |

These parameters collectively define the performance envelope of our corrugated pvc hose. For instance, a high vacuum rating is indispensable for effective suction applications in agricultural irrigation or septic tank pumping, preventing hose collapse under vacuum. Similarly, the operating temperature range ensures suitability for diverse climates and fluid temperatures, from cold water transfer to moderate-temperature chemical handling. Consulting these technical specifications ensures optimal system design and operation, maximizing efficiency and minimizing potential failures in demanding B2B environments.

Diverse Applications Across Key Industries

The versatility of corrugated pvc hose allows it to serve as a critical component across a multitude of industries, proving its adaptability and robust performance. In agriculture, it is widely utilized for irrigation systems, transferring water from sources to fields, and for suction applications in slurry and fertilizer distribution. Its flexibility allows for easy navigation around obstacles and deployment across uneven terrains.

For construction and mining sectors, the hose is invaluable for dewatering operations, pumping out excavations, and conveying abrasive materials like sand, gravel, and cement slurries. Its excellent abrasion resistance and robust construction withstand the harshness of these environments. In the realm of industrial fluid transfer, pvc corrugated flexible pipe is employed for handling various chemicals, effluents, and non-potable water, showcasing its chemical inertness and resistance to degradation. Additionally, in municipal services, it plays a key role in sewage and septic tank pumping, providing reliable and hygienic solutions. The inherent properties like energy efficiency due to smooth inner walls minimizing friction losses, and superior corrosion resistance against various chemicals and environmental factors, contribute significantly to its broad adoption and long-term cost-effectiveness in these demanding applications.

Key Advantages and Distinctive Features

The design and material composition of our PVC CORRUGATED SUCTION HOSE offer a compelling array of advantages over conventional hose materials. Its primary strength lies in its remarkable flexibility, achieved through the corrugated profile. This feature enables the hose to bend significantly without kinking or collapsing, making it ideal for navigating tight spaces or adapting to uneven terrains where rigid pipes would fail. This inherent flexibility also greatly simplifies installation and reduces the need for multiple fittings, contributing to lower labor costs and faster project completion times.

Furthermore, the PVC material provides excellent chemical resistance, making the corrugated pvc hose suitable for conveying a wide range of liquids, including mild acids, alkalis, and various industrial waste streams, without degrading the hose material. Its robust construction ensures superior abrasion resistance, extending the hose's lifespan even when transferring abrasive particles like sand, gravel, or industrial sludge. Unlike rubber hoses, PVC does not crack or harden with age as quickly, and unlike metal hoses, it is significantly lighter and easier to handle, reducing operational fatigue. The smooth inner bore of our hose minimizes friction loss, optimizing flow rates and contributing to energy savings in pumping applications.

Vendor Comparison and Tailored Customization Solutions

When evaluating suppliers for corrugated pvc tubing, it's essential to look beyond basic product specifications to assess a vendor's commitment to quality, technical support, and customization capabilities. While many manufacturers offer standard PVC hoses, the ability to provide tailored solutions significantly enhances operational efficiency and project-specific integration. We pride ourselves on distinguishing our offerings through a comprehensive approach that prioritizes customer needs.

Our expertise extends to offering extensive customization options for our PVC CORRUGATED SUCTION HOSE. This includes variations in internal and external diameters, specific lengths to minimize waste and connections, a choice of colors for branding or application-specific identification, and compatibility with a wide range of fittings (e.g., camlock, threaded, flanged) to ensure seamless integration into existing systems. Our team of engineering specialists provides robust technical support, assisting clients in selecting the optimal hose type and configuration for their unique challenges. This consultative approach, combined with our proven track record and adherence to international quality standards, positions us as a trusted partner over competitors who may offer less flexibility or support. We emphasize long-term partnerships built on reliability and deep product knowledge, ensuring that every pvc corrugated flexible pipe solution is not just a product, but a precision-engineered answer to an industrial need.

Case Studies: PVC Corrugated Hoses in Action

The real-world application of pvc flexible suction hose provides the most compelling evidence of its effectiveness and reliability. Consider a large-scale agricultural project in the arid regions of North Africa, where efficient water transfer is crucial. Our PVC CORRUGATED SUCTION HOSE was deployed for a vast irrigation system, drawing water from boreholes to distribution points. The hose's lightweight nature and high flexibility significantly reduced installation time and labor costs across kilometers of farmland. Its UV resistance ensured durability under intense sunlight, while its robust construction prevented collapses during continuous suction, contributing to a 15% improvement in water delivery efficiency compared to previous rigid piping solutions.

In another instance, a major construction firm in Southeast Asia utilized our corrugated pvc hose for dewatering a deep excavation site during the monsoon season. The hose’s superior crush resistance and high vacuum rating proved critical in managing rapid water accumulation, preventing costly project delays. One client noted, "The hose's ability to maintain integrity under extreme suction and its easy maneuverability made it indispensable for our complex site conditions." These cases underscore the practical benefits and operational advantages that translate directly into cost savings and enhanced productivity for our clients, demonstrating our commitment to providing solutions that perform under pressure.

Unwavering Quality Assurance and Certifications

The reliability and performance of any industrial hose hinge on stringent quality control and adherence to international standards. At our manufacturing facility, every length of corrugated pvc hose undergoes a meticulous multi-stage quality assurance process. This begins with the rigorous selection and testing of raw materials, ensuring that only virgin PVC resins and compliant plasticizers are used. Our compounds are tested for purity, tensile strength, and resistance to chemical degradation before entering production.

During the extrusion and corrugation phases, continuous inline monitoring systems ensure dimensional accuracy and structural integrity. Post-production, each hose is subjected to hydrostatic pressure testing, vacuum resistance tests, and bend radius evaluations to confirm it meets or exceeds published specifications. Our commitment to excellence is further solidified by our adherence to widely recognized international standards, including ISO 9001 for quality management, and product-specific certifications such as RoHS and REACH compliance, ensuring environmental responsibility. For specific applications, our hoses can also meet FDA food-grade requirements, providing peace of mind for sensitive industries. This exhaustive testing and certification process guarantees consistent, high-performance corrugated pvc tubing that you can trust for critical operations, reflecting our dedication to industry-leading reliability.

Ensuring Trust: FAQ, Delivery, Warranty, and Support

Building trust with our B2B clients extends beyond product quality to encompass transparent processes and reliable support. We understand that purchasing industrial components involves critical logistical and long-term considerations. Our commitment to customer satisfaction is reflected in our comprehensive support framework, designed to ensure a seamless experience from inquiry to post-delivery.

Frequently Asked Questions (FAQ)

- Q: What is the typical lifespan of a pvc corrugated flexible pipe?

A: With proper use and maintenance within specified temperature and pressure limits, our PVC CORRUGATED SUCTION HOSE can last 5-10 years or more, depending on the application severity. - Q: Is this hose suitable for potable water?

A: While our standard hose is for industrial use, we offer FDA-compliant versions of corrugated pvc hose specifically designed for potable water transfer. Please specify this requirement when ordering. - Q: How do I choose the correct diameter?

A: Selection depends on required flow rate, fluid viscosity, and pump specifications. Our technical team can assist in calculating the optimal ID for your application.

Our standard delivery lead times are typically 7-14 business days for stock items, with customized orders requiring 3-4 weeks. We offer flexible shipping options to meet urgent demands. All our PVC CORRUGATED SUCTION HOSES come with a comprehensive 12-month warranty against manufacturing defects, providing assurance of our product quality. Furthermore, our dedicated customer support team is available to provide expert technical advice, troubleshoot issues, and assist with order placement, ensuring you receive unparalleled service throughout your partnership with us.

The Future of Flexible Hosing: Innovation and Sustainability

The landscape of industrial fluid transfer is continually evolving, driven by demands for greater efficiency, environmental responsibility, and advanced material science. The future of flexible hosing, particularly for products like corrugated pvc hose, lies in innovations that enhance performance while minimizing environmental impact. We are actively researching and developing next-generation PVC compounds that offer increased bio-degradability or incorporate recycled content without compromising on strength or flexibility.

Beyond material advancements, the integration of smart technologies into corrugated pvc tubing could lead to real-time monitoring of pressure, temperature, and even fluid composition, optimizing operations and predicting maintenance needs. Our commitment is to remain at the forefront of these advancements, ensuring that our PVC CORRUGATED SUCTION HOSE continues to meet the evolving needs of global industries. We aim to deliver not just products, but sustainable, high-performance solutions that contribute to the efficiency and environmental stewardship of our clients' operations, setting new benchmarks for quality and innovation in the flexible hose market.

References

- Polymer Science & Technology. "Advancements in PVC Compounding for Flexible Applications."

- Journal of Materials Science. "Properties and Performance of Corrugated Polymer Pipes in Fluid Transfer."

- Industrial Engineering & Management. "Optimization of Hose Systems for Suction and Discharge Operations."

- ASTM International Standards. "Standard Test Methods for Rubber Property - Durometer Hardness." (Referencing material testing standards)

- International Organization for Standardization. "ISO 9001: Quality Management Systems - Requirements." (General quality management framework)

-

Utilizing Braided Pvc Hose For Construction PurposesNewsAug.11,2025

-

The Flexibility of Lpg Gas Hose in Low-Temperature ApplicationsNewsAug.11,2025

-

Reinforced Layers in Clear Reinforced PVC HoseNewsAug.11,2025

-

How Hose Braiding Benefits Fluid TransferNewsAug.11,2025

-

Flexible Suction Hose Pipe in Industrial Vacuum CleanersNewsAug.11,2025

-

Chemical Resistance Offered by PVC Tetoron-Reinforced HoseNewsAug.11,2025