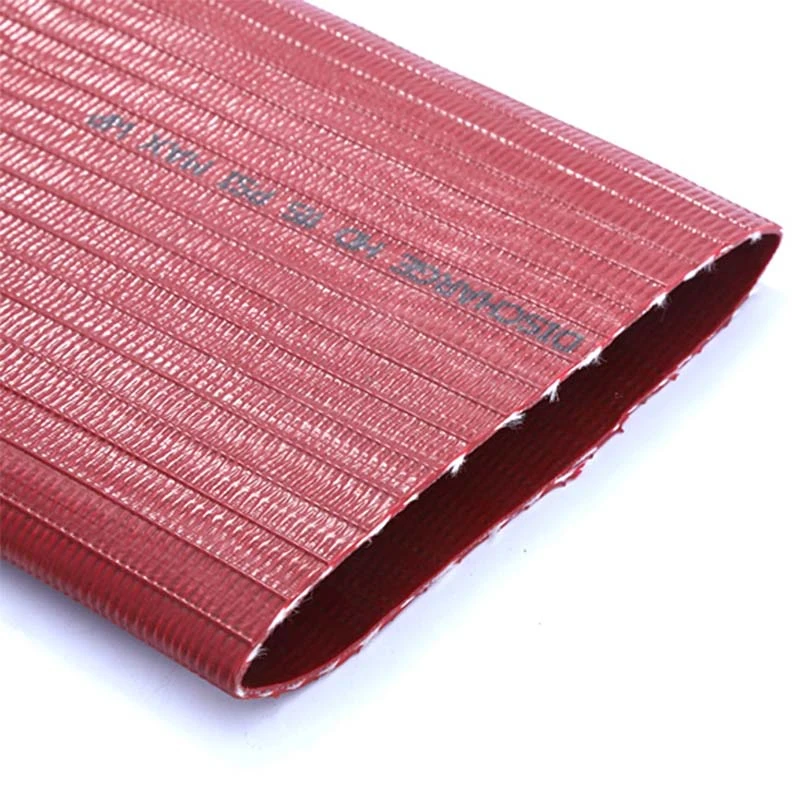

600 psi hose

Understanding 600 PSI Hose Key Features and Applications

When it comes to industrial and commercial fluid transfer systems, choosing the right hose is crucial for ensuring efficiency, safety, and reliability. One prevalent type is the 600 PSI hose, which has become a popular choice in various applications. This article delves into the characteristics, benefits, and typical uses of 600 PSI hoses, helping you understand why they are a critical component in many environments.

What is a 600 PSI Hose?

A 600 PSI hose is designed to withstand a pressure of up to 600 pounds per square inch (psi), making it suitable for transferring fluids under significant pressure. These hoses are commonly constructed from durable materials such as rubber, PVC, or thermoplastic elastomers. The construction of a 600 PSI hose typically involves multiple layers, including a reinforced exterior and a strong inner tube, which work together to provide durability and flexibility.

Key Features

1. Pressure Rating The most significant feature of a 600 PSI hose is its ability to handle high-pressure applications. This makes it suitable for use in various industries, including agriculture, construction, and manufacturing.

2. Construction Material Many 600 PSI hoses are made from high-quality synthetic rubber or thermoplastic materials, which provide resistance to abrasion, chemicals, and environmental exposure. This robust construction ensures longevity and reliability in demanding conditions.

3. Size Variability 600 PSI hoses come in various diameters and lengths, allowing users to select the appropriate size for their specific applications. This flexibility is crucial in complex systems where different hose sizes may be necessary.

4. Temperature Resistance Many of these hoses can operate effectively in a wide range of temperatures, which is essential for applications involving hot or cold liquids. Understanding the temperature ratings is essential when selecting the right hose for your application.

5. Compatibility with Accessories 600 PSI hoses are designed to be compatible with numerous fittings and accessories, making it easy to incorporate them into existing systems without major modifications.

600 psi hose

Benefits of Using 600 PSI Hoses

1. Safety The increased pressure rating reduces the risk of hose failure under high-pressure conditions, which can lead to hazardous situations. Using a hose rated appropriately for its intended application is critical for workplace safety.

2. Efficiency With their robust construction, 600 PSI hoses minimize pressures drops and maximize fluid flow, contributing to overall system efficiency. This is particularly important in industrial applications where fluid delivery speed is essential.

3. Versatility The adaptability of 600 PSI hoses makes them a go-to choice for a diverse range of applications, from pumping water to transferring chemicals. This versatility allows businesses to standardize their hose types, simplifying maintenance and replacement.

4. Cost-Effectiveness Though they might require a higher initial investment than lower-rated hoses, the durability and longevity of 600 PSI hoses often translate into lower overall costs. Reduced downtime due to hose failures can also save money in lost productivity.

Applications

600 PSI hoses find use in various industries and applications, including

- Agriculture Used for irrigation systems, liquid fertilizer applications, and chemical spraying. - Construction Employed for conveying water, concrete, and other materials under pressure, vital for construction projects. - Manufacturing Utilized in machinery and equipment for hydraulic applications and high-pressure fluid transfers. - Automotive Found in automotive repair shops for fluid transfer, including oil, coolant, and other essential fluids.

Conclusion

In summary, 600 PSI hoses are indispensable tools in many industries, boasting features that enhance safety, efficiency, and versatility. Their ability to handle high pressure and challenging conditions makes them suitable for a wide range of applications, from agricultural tasks to industrial processes. Understanding the benefits and characteristics of these hoses is essential for making informed decisions when optimizing fluid transfer systems. As with any industrial component, investing in the right hose ensures reliability and efficiency, contributing to the success of your operations.

-

Unveiling the Landscape of PVC Air Hoses and Comparative AnalysisNewsJun.24,2025

-

Unraveling the World of Specialized Braided Hoses and Their AlternativesNewsJun.24,2025

-

The Essential Role of PVC Hoses in Air - Related SystemsNewsJun.24,2025

-

Precision - Engineered Tubing and Braiding SolutionsNewsJun.24,2025

-

Pneumatic Tubing and Braided Hoses: Powering Industrial OperationsNewsJun.24,2025

-

Comparative Analysis and Insights into Air Hoses: PVC vs Rubber and BeyondNewsJun.24,2025