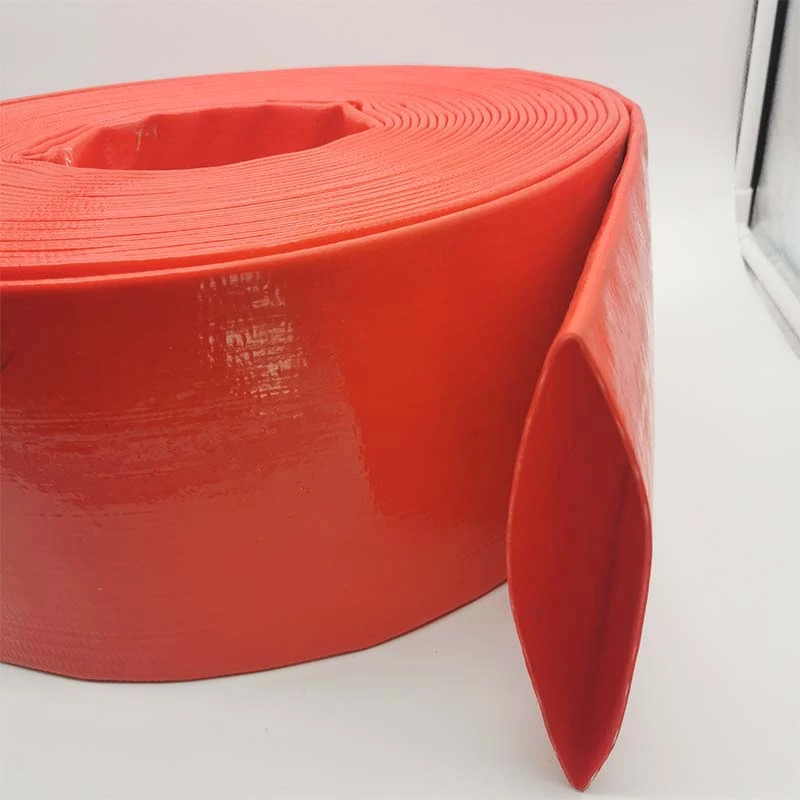

air pvc pipe

Understanding Air PVC Pipes Applications, Benefits, and Considerations

Air PVC pipes, short for polyvinyl chloride pipes designed specifically for air transmission, play a crucial role in various industries. These pipes are known for their lightweight, durability, and resistance to corrosion, making them a popular choice for transporting compressed air in industrial settings, pneumatic systems, and even in HVAC applications. Understanding the features, benefits, and potential drawbacks of air PVC pipes can help businesses make informed decisions about their piping infrastructure.

Applications of Air PVC Pipes

Air PVC pipes are widely used in several applications, primarily due to their ability to efficiently convey air with minimal pressure loss. One of the main industries that utilize these pipes is manufacturing. In manufacturing plants, compressed air is often used for powering tools, machinery, and equipment. The use of air PVC pipes ensures that compressed air reaches various points of use without significant leakage or pressure drop, which can enhance overall productivity.

Another common application is in HVAC systems, where air PVC pipes can facilitate the distribution of air in residential, commercial, and industrial buildings. Their lightweight nature allows for easy installation and modification, which is essential in dynamic environments where configurations might change over time.

Additionally, air PVC pipes can be found in agricultural applications, such as greenhouse ventilation systems. They help distribute air evenly within the greenhouse, promoting optimal growing conditions for plants.

Benefits of Using Air PVC Pipes

1. Lightweight and Easy to Handle One of the primary advantages of air PVC pipes is their lightweight nature. This feature makes them easy to transport and install, reducing labor costs and time during the installation process.

2. Durability Air PVC pipes are resistant to corrosion and can withstand a range of environmental conditions. Unlike metal pipes that may rust over time, PVC does not corrode, ensuring a longer service life and lower maintenance costs.

air pvc pipe

3. Cost-Effective Generally, air PVC pipes are more affordable than other piping materials like metal or fiberglass. Their lower initial cost, combined with reduced maintenance and replacement expenses, makes them an attractive option for businesses.

4. Smooth Interior Surface The smooth interior walls of air PVC pipes help to reduce turbulence and pressure loss, ensuring efficient air flow. This characteristic is essential in applications where maintaining a steady air supply is critical.

5. Chemical Resistance PVC is resistant to various chemicals, meaning that air PVC pipes can be used in environments where they may be exposed to harsh substances without degrading.

Considerations When Using Air PVC Pipes

Despite their numerous benefits, there are some considerations to keep in mind when using air PVC pipes. One primary concern is the temperature limitations of PVC. While they can withstand a range of temperatures, extreme heat can cause PVC to weaken or deform. Therefore, it is essential to assess the temperature conditions of the intended environment before choosing air PVC pipes.

Another consideration is the pressure rating of the pipes. Different air PVC pipes are designed to handle specific pressure ranges. It is crucial to select pipes that can withstand the pressure requirements of your system to prevent failures and ensure safety.

Finally, while PVC is generally resistant to many chemicals, it is wise to verify compatibility with any specific substances that may come into contact with the pipes. Certain chemicals can degrade PVC, leading to leaks or structural failures.

Conclusion

Air PVC pipes offer an efficient, cost-effective solution for transporting compressed air across various industries. Their lightweight nature, durability, and resistance to corrosion make them suitable for multiple applications, ranging from manufacturing to HVAC systems. However, it is essential to consider temperature limitations, pressure ratings, and chemical compatibility when selecting air PVC pipes for your projects. Understanding these factors will ensure the optimal performance of your air transmission systems and contribute to the overall efficiency of your operations. As industries continue to evolve, so will the demand for reliable and effective piping solutions, making air PVC pipes a staple in modern infrastructure.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025