pvc fiber hose

Understanding PVC Fiber Hose A Versatile Solution for Various Applications

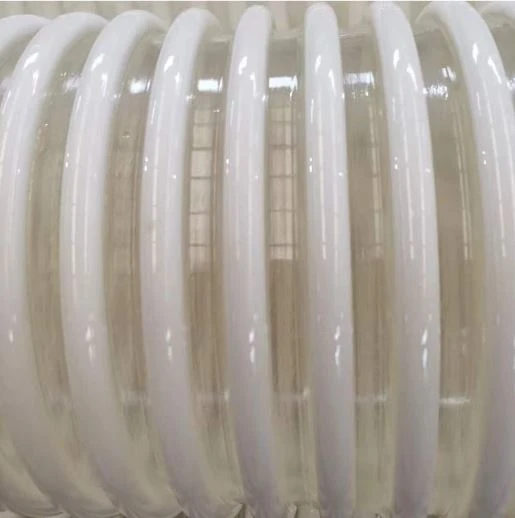

PVC fiber hose, made from polyvinyl chloride (PVC) and reinforced with woven fiber, has emerged as a popular choice for a wide range of industrial and domestic applications. Its unique composition brings together the flexibility of plastic and the durability of fiber reinforcement, offering a versatile solution that meets various performance requirements.

Composition and Characteristics

The primary component of PVC fiber hose is polyvinyl chloride, a robust and lightweight thermoplastic material. This makes the hose resistant to abrasion, chemicals, and UV rays, contributing to its longevity and reliability even in harsh environments. The fiber reinforcement—often made from polyester or similar materials—enhances the hose's tensile strength and prevents it from collapsing under pressure, which is a critical aspect for ensuring consistent performance in fluid transfer applications.

One of the key characteristics of PVC fiber hoses is their flexibility. Unlike traditional rubber hoses, PVC fiber hoses can bend and twist without kinking, making them ideal for use in tight spaces or situations requiring maneuverability. Additionally, they are typically available in a range of diameters and lengths, allowing for customization to suit specific needs.

Applications

PVC fiber hoses are utilized in a variety of settings due to their robustness and adaptability. In the agricultural sector, they are frequently used for watering systems, fertilizers, and pesticides due to their resistance to chemicals. In manufacturing and industrial applications, these hoses serve as conduits for air, water, and various liquids, catering to both high-pressure and low-pressure scenarios.

pvc fiber hose

The construction industry also benefits from the use of PVC fiber hoses, particularly for handling cement, plaster, and other heavy materials. Their lightweight nature allows for easy handling, while the fiber reinforcement prevents rupture during demanding tasks. Additionally, in the realm of healthcare, PVC fiber hoses are used in medical devices and equipment, where their non-toxic properties are crucial.

Advantages Over Alternative Materials

When compared to other hose materials, such as rubber or metal, PVC fiber hoses offer several advantages. They are typically more cost-effective, lightweight, and easier to store and transport. Moreover, the smooth interior surface of PVC fiber hoses aids in minimizing friction loss, ensuring more efficient fluid transfer.

Another noteworthy advantage is their resistance to weathering and earth elements. While rubber hoses may degrade and lose flexibility over time due to exposure to sunlight and moisture, PVC fiber hoses maintain their integrity and performance, making them a reliable choice for outdoor applications.

Conclusion

In conclusion, PVC fiber hoses represent a practical and efficient option for various fluid and air transfer needs across multiple industries. Their unique combination of durability, flexibility, and chemical resistance makes them an essential tool for both professionals and DIY enthusiasts. As industries continue to evolve and the demand for versatile, reliable materials grows, the PVC fiber hose will likely remain an invaluable asset, supporting innovation and efficiency in operations worldwide. Whether for agricultural, industrial, or domestic use, the PVC fiber hose is a testament to modern engineering and material science, providing solutions that stand the test of time.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025