Custom Braided Hoses for Enhanced Performance and Durability in Fluid Transfer Applications

Custom Braided Hose Revolutionizing Fluid Transfer Solutions

In industrial applications, the efficient transfer of fluids is crucial for the smooth operation of machinery and processes. Among the various components that facilitate this transfer, hoses play a vital role. Custom braided hoses have emerged as one of the most effective solutions, offering versatility, durability, and superior performance in a wide range of applications.

What are Custom Braided Hoses?

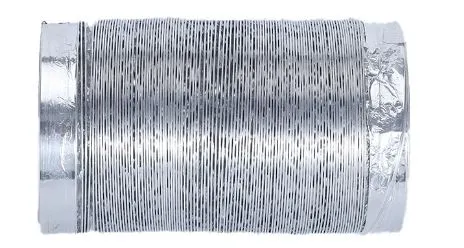

Custom braided hoses are flexible tubes that are reinforced with braided materials, facilitating the safe and efficient passage of fluids. These hoses are designed specifically to meet the unique needs of different industries, including automotive, aerospace, chemical processing, and oil and gas.

The construction of braided hoses typically involves an inner tube made from materials such as rubber or thermoplastic, which is then reinforced with a braided layer made of materials like stainless steel, nylon, or polyester. This braided layer provides added strength and durability, making the hoses resistant to high pressures and temperatures, as well as various types of wear and tear.

Benefits of Custom Braided Hoses

1. High Pressure and Temperature Resistance One of the most significant advantages of custom braided hoses is their ability to withstand high pressures and temperatures. The braided reinforcement allows these hoses to handle demanding conditions without compromising their structural integrity. This feature is essential in industries where fluids need to be transported under high pressure, such as hydraulic systems.

2. Chemical Compatibility Many industries require hoses that can handle aggressive chemicals and corrosive substances. Custom braided hoses can be tailored to use materials that are resistant to various chemicals, ensuring safe and effective fluid transfer in chemical processing applications. This customization allows businesses to work with a wider range of substances without worrying about hose failure.

3. Flexibility and Versatility Custom braided hoses are highly flexible, allowing them to bend and curve easily to accommodate different layouts and spaces. This adaptability is particularly useful in applications where space is constrained, or where the hose needs to navigate around obstacles.

custom braided hose

4. Reduced Risk of Kinking and Collapse The braided construction of these hoses helps to maintain their shape, reducing the risk of kinking or collapsing under pressure. This feature ensures a consistent flow of fluids and minimizes downtime due to maintenance or replacement.

5. Custom Lengths and Diameters One of the primary advantages of custom braided hoses is the ability to order hoses in specific lengths and diameters. This customization ensures that businesses receive hoses that perfectly fit their equipment and requirements, eliminating the need for adapters or modifications.

6. Durability and Longevity The materials used in custom braided hoses are often designed for long-term use, which translates to lower replacement costs and reduced maintenance needs. This durability means that businesses can rely on their hoses to perform reliably over time, contributing to overall operational efficiency.

Applications of Custom Braided Hoses

Custom braided hoses find applications across a myriad of industries. In the automotive sector, they are commonly used for fuel systems, cooling systems, and oil transfer. Aerospace applications demand hoses that can withstand extreme conditions, making braided options ideal for hydraulic and fuel systems.

In the oil and gas industry, custom braided hoses are essential for transporting various fluids safely from one location to another. Similarly, in manufacturing and chemical processing, these hoses are crucial for handling substances that require specialized materials to prevent degradation.

Conclusion

Custom braided hoses are a vital component in modern fluid transfer systems, offering an array of benefits that enhance performance and reliability in various industries. Their adaptability, durability, and ability to withstand harsh conditions make them an indispensable part of many applications. As industries continue to evolve and require more specialized solutions, the demand for custom braided hoses will only grow. Companies looking to improve their fluid transfer systems should consider investing in these high-quality, tailored hoses to enhance efficiency and operational performance.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025