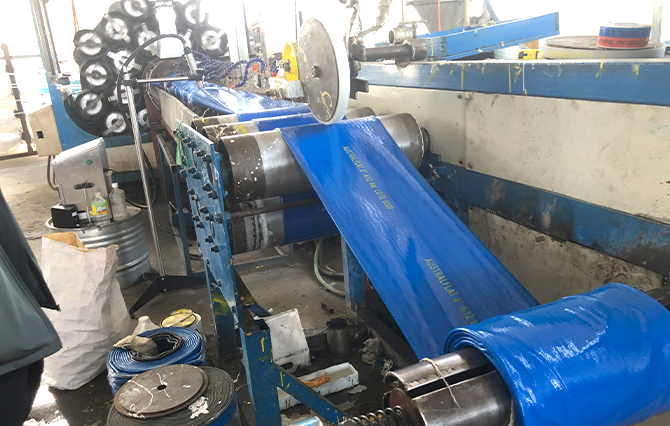

polyurethane tube

Understanding Polyurethane Tubes Versatility and Applications

Polyurethane tubes have gained significant attention in various industries due to their unique properties and versatility. Made from polyurethane elastomers, these tubes offer a combination of flexibility, durability, and resistance to abrasions and chemicals. This article explores the characteristics, applications, and benefits of using polyurethane tubes in different sectors.

What is Polyurethane?

Polyurethane is a type of polymer composed of organic units joined by carbamate (urethane) links. It can be formulated to be rigid or flexible, depending on the specific requirements of an application. This adaptability is one of the key advantages of polyurethane. Its structure allows it to perform exceptionally well in environments that require both strength and resilience.

Properties of Polyurethane Tubes

1. Flexibility and Elasticity Polyurethane tubes exhibit excellent elasticity, making them ideal for applications that require bending and flexibility without breaking or cracking.

2. Chemical Resistance These tubes are resistant to a variety of chemicals, including oils, solvents, and some acids and bases. This property makes polyurethane tubes suitable for industries such as automotive, pharmaceutical, and food processing.

3. Durability Polyurethane is known for its toughness, which means that these tubes can withstand heavy wear and tear. They are less likely to rupture under pressure compared to standard rubber or plastic tubes.

4. Temperature Stability Polyurethane tubes can retain their properties across a wide temperature range, typically from -40°C to 80°C. This temperature stability allows them to be used in challenging environments, such as refrigeration or hot water applications.

polyurethane tube

Applications of Polyurethane Tubes

Due to their advantageous properties, polyurethane tubes are utilized in numerous industries

1. Automotive Industry In the automotive sector, these tubes are often used for fuel lines, brake lines, and in the hydraulic systems of vehicles due to their high-pressure tolerance and chemical resistance.

2. Medical Applications Polyurethane tubes are prevalent in medical devices, including catheters and drainage tubes. Their biocompatibility makes them safe for use in direct contact with bodily fluids.

3. Industrial Applications Various machines and manufacturing processes require high-quality tubing for pneumatic systems, air brakes, and coolant lines. Polyurethane tubes provide the reliability needed in these demanding environments.

4. Construction and Mining The construction industry benefits from polyurethane tubes as they are used for applications such as water supply lines and hydraulic hoses. Their resistance to abrasion makes them suitable for use in rugged environments.

5. Food and Beverage Industry Polyurethane tubes are also used in food processing due to their ability to resist bacteria and other contaminants, ensuring safe transport of liquids.

Conclusion

Polyurethane tubes are a remarkable solution for many industries due to their versatility and superior properties. As technology advances, the applications of polyurethane materials are likely to expand, leading to even more innovative uses in various sectors. Businesses looking for reliable and high-performance tubing solutions would do well to consider polyurethane as a primary option. With their unique combination of flexibility, durability, and resistance to environmental factors, polyurethane tubes are essential components in modern engineering and manufacturing processes.

-

Unrivaled Performance and Applications of PU Pneumatic Hoses and TubesNewsJun.11,2025

-

The Transparent World of Industrial Tubing and Hosing SolutionsNewsJun.11,2025

-

The Intricate World of Pneumatic Conduits: Tubes and HosesNewsJun.11,2025

-

The Dynamic Landscape of Pneumatic Conduits: Unraveling Key ComponentsNewsJun.11,2025

-

The Diverse Applications and Significance of Transparent PVC TubingNewsJun.11,2025

-

High - Pressure Pneumatic Tubing and Systems: An In - Depth LookNewsJun.11,2025