Safety Guidelines for Using Oxygen and Acetylene Welding Hoses in Industrial Settings

The Importance of Oxygen and Acetylene Hoses in Welding Operations

Welding is a critical process in metal fabrication and assembly, facilitating various industries from construction to automotive. At the heart of many welding operations are two essential gases oxygen and acetylene. The combination of these gases produces a flame that can reach intense temperatures needed for welding and cutting metals. However, to safely and effectively utilize these gases, specialized hoses are necessary. This article delves into the significance of oxygen and acetylene hoses in welding, discussing their functions, construction, safety measures, and maintenance.

Function of Oxygen and Acetylene Hoses

Oxygen and acetylene hoses serve the primary function of transporting gases from their cylinders to the welding torch. Each gas has its specific hose, clearly distinguishable by color codes—typically green for oxygen and red for acetylene. This color coding is critical to prevent any mix-up, which could lead to dangerous situations.

The hoses are designed to withstand high pressure, as both gases are stored under significant pressure in their cylinders. The oxygen hose delivers pure oxygen, which promotes combustion, while the acetylene hose transports the fuel gas needed to sustain that combustion. The careful regulation of these gases through the welding torch allows welders to create an adjustable flame, which is pivotal in achieving the desired weld quality.

Construction of the Hoses

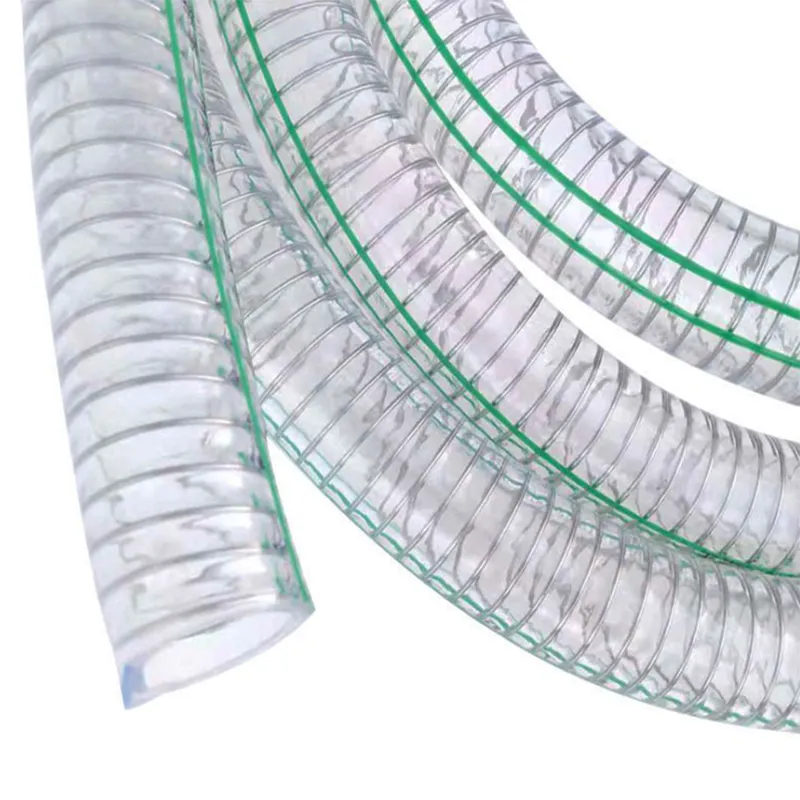

The hoses designed for oxygen and acetylene are constructed from durable materials that can handle the rigors of welding environments. They are typically made from a combination of synthetic rubber and other compounds that provide flexibility, resilience, and resistance to wear and tear.

One of the most important factors in hose construction is ensuring that they are resistant to the damaging effects of heat and certain chemicals. The hoses are reinforced to prevent kinking, which can impede gas flow and create pressure build-ups. Furthermore, proper fittings and connectors are used to ensure a tight seal, preventing gas leaks that could lead to hazardous conditions.

Safety Considerations

oxygen and acetylene hoses

Safety is paramount in any welding operation, and the proper use of oxygen and acetylene hoses is a critical part of that equation. First and foremost, regular inspections of the hoses for wear and tear are essential. Welders should look for cracks, fraying, or any signs of damage that could compromise the integrity of the hoses.

When storing the hoses, it is vital to keep them in a cool, dry place, away from direct sunlight and heat sources. This helps to prevent any degradation of the materials. Additionally, hoses should always be disconnected from the cylinders when not in use, and any leaks detected must be reported and repaired immediately.

Training in the correct handling and use of oxygen and acetylene hoses is equally important. Welders should be educated on the properties of the gases they are working with, the implications of improper handling, and the importance of maintaining a clean workspace free from flammable materials.

Maintenance of Hoses

The longevity and performance of oxygen and acetylene hoses greatly depend on their maintenance. Regular cleaning is necessary to remove any dust, dirt, or contaminants that might accumulate on the hoses. It's advisable to use a mild detergent and water solution for cleaning, followed by thoroughly rinsing and drying them before storage.

Moreover, storing hoses coiled without kinks helps to maintain their shape and prevents early wear. Ensuring that hoses are free from twists and kinks during operation is equally vital, as this maintains consistent gas flow and minimizes the risk of bursts or leaks.

Conclusion

In conclusion, oxygen and acetylene hoses are indispensable tools in the welding industry, providing essential functionality while posing certain safety risks. Proper understanding of their function, construction, safety measures, and maintenance can significantly enhance a welder's efficiency and safety. As industries continue to evolve, the essential role of these hoses in welding operations underscores the importance of adhering to best practices for their use and care. By prioritizing these factors, welders can ensure successful outcomes in their projects while maintaining a safe working environment.

-

Unrivaled Performance and Applications of PU Pneumatic Hoses and TubesNewsJun.11,2025

-

The Transparent World of Industrial Tubing and Hosing SolutionsNewsJun.11,2025

-

The Intricate World of Pneumatic Conduits: Tubes and HosesNewsJun.11,2025

-

The Dynamic Landscape of Pneumatic Conduits: Unraveling Key ComponentsNewsJun.11,2025

-

The Diverse Applications and Significance of Transparent PVC TubingNewsJun.11,2025

-

High - Pressure Pneumatic Tubing and Systems: An In - Depth LookNewsJun.11,2025