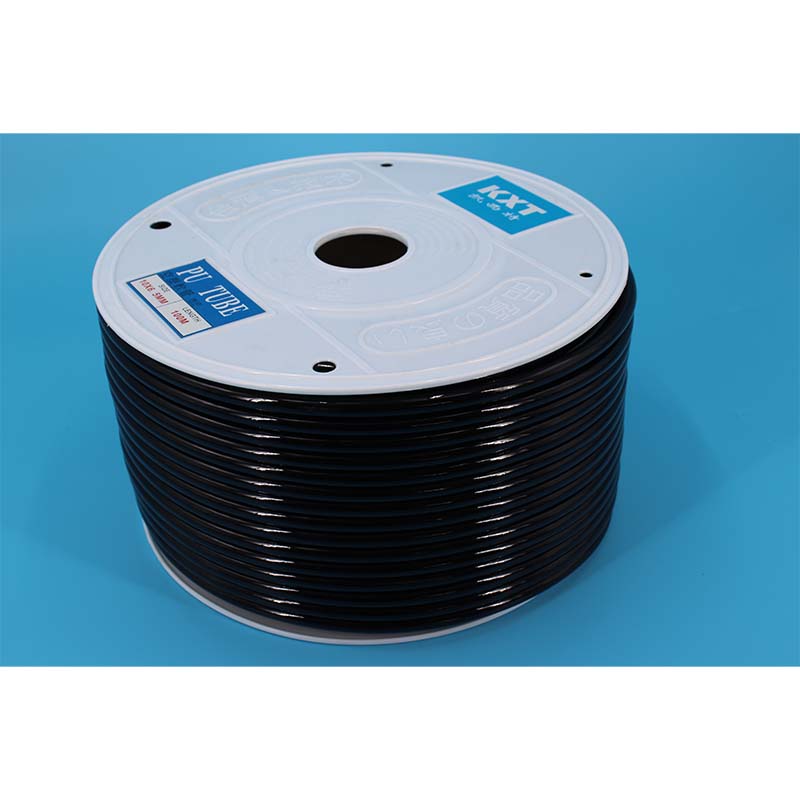

Polyurethane Tube Manufacturers: Flexible & Durable PU Tubes

The Critical Role of Advanced Polyurethane Tubing in Modern Industrial Applications

In the intricate landscape of modern industrial automation and control systems, the reliability and performance of pneumatic components are paramount. Among these, tubing plays a foundational role, transferring air and other gases to power machinery, actuate valves, and facilitate precise movements. Polyurethane (PU) tubing has emerged as a superior choice due to its unique blend of flexibility, durability, and resistance properties, outperforming traditional materials like nylon or PVC in many demanding environments. Understanding the capabilities and manufacturing excellence of leading polyurethane tube manufacturers is crucial for sourcing high-quality solutions that ensure operational efficiency and longevity.

This comprehensive guide delves into the world of industrial-grade PU tubing, exploring its advanced manufacturing processes, critical technical parameters, diverse application scenarios, and the stringent quality standards upheld by expert producers. We aim to equip B2B decision-makers and technical personnel with the insights needed to select optimal tubing solutions, highlighting how innovative design and robust production methodologies contribute to the overall performance and cost-effectiveness of pneumatic systems. From understanding material science to evaluating supplier capabilities, this information is designed to foster informed purchasing decisions and long-term reliability in your operations.

Precision in Production: The Advanced Manufacturing Process of PU Pneumatic Hoses

The creation of high-performance PU Pneumatic tube Hose involves a meticulously controlled extrusion process, setting leading polyurethane tube manufacturers apart. This process begins with the careful selection of thermoplastic polyurethane (TPU) granules, chosen for their specific shore hardness, chemical resistance, and thermal properties. These granules are precisely blended with stabilizers, colorants, and other proprietary additives to achieve the desired tube characteristics, such as UV resistance or specific colors for coding. Consistency in material composition is paramount to ensure uniform product performance across batches.

The blended material is then fed into a high-precision extruder, where it is heated to a molten state and forced through a die to form the continuous tube profile. Critical parameters such as temperature profiles, extrusion speed, and cooling rates are precisely managed to control dimensional accuracy, wall thickness uniformity, and the overall structural integrity of the tube. Post-extrusion, the tube undergoes immediate cooling in a controlled environment, often involving water baths, to solidify its form. In-line laser gauges and ultrasonic sensors continuously monitor the outer diameter, inner diameter, and wall thickness, ensuring strict adherence to specifications. This real-time feedback loop allows for immediate adjustments, minimizing deviations and ensuring a consistent, high-quality product ready for cutting and packaging.

Essential Technical Parameters and Performance Metrics for PU Tubing

Understanding the technical specifications of pu pneumatic hose is vital for selecting the appropriate product for any given application. Key parameters directly influence the tube's suitability for specific pressure ranges, environmental conditions, and mechanical stresses. For instance, the Shore Hardness, typically Shore A for PU tubing, dictates its flexibility and abrasion resistance; a higher Shore A value indicates greater rigidity. Working pressure and burst pressure ratings are critical for safety and operational efficiency, indicating the maximum continuous and intermittent pressure the tube can withstand without failure, respectively. These figures are often tested at room temperature, with derating factors applied for higher temperatures.

Temperature range defines the operational limits, ensuring the tube maintains its physical properties without becoming brittle in cold or soft in heat. Bend radius is crucial for routing in confined spaces, indicating the tightest curve the tube can form without kinking or compromising flow. Furthermore, resistance to various chemicals, oils, and hydrolysis needs to be considered depending on the environment. Leading pu tube manufacturers often provide detailed chemical compatibility charts. Adherence to international standards like ISO 9001 for quality management and environmental directives such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) signifies a manufacturer's commitment to both product quality and environmental responsibility.

| Parameter | Typical Range/Value (PU Pneumatic Tube Hose) | Significance |

|---|---|---|

| Material | Thermoplastic Polyurethane (TPU) | Excellent flexibility, abrasion resistance, and memory characteristics. |

| Hardness (Shore A) | 90A to 98A | Determines flexibility and resistance to crushing/kinking. |

| Outer Diameter (OD) | 3mm to 16mm (standard metric) / 1/8" to 1/2" (standard imperial) | Compatibility with push-to-connect fittings. |

| Working Pressure | Up to 10 Bar (145 PSI) @ 20°C (size dependent) | Maximum continuous operating pressure. |

| Burst Pressure | Typically 3:1 or 4:1 safety factor over working pressure | Pressure at which the tube will typically fail. |

| Temperature Range | -20°C to +80°C (-4°F to +176°F) | Operational limits without property degradation. |

| Minimum Bend Radius | Varies by OD, e.g., 10mm for 6mm OD tube | Smallest curve without kinking or flow restriction. |

| Abrasion Resistance | Excellent, typically superior to Nylon or PVC | Withstands wear from friction and contact. |

| Fluid Compatibility | Compressed Air, Inert Gases, select oils/chemicals | Ensures chemical stability and longevity in contact with various media. |

Diverse Applications and Industry Impact of PU Pneumatic Tubing

The exceptional characteristics of PU pneumatic hose make it indispensable across a wide array of industrial sectors. In industrial automation, its flexibility and excellent bend memory are crucial for dynamic applications such as robotic arms and automated assembly lines, where continuous motion and tight routing are common. Its light weight helps reduce the load on robotic systems, improving responsiveness and energy efficiency. Similarly, in packaging machinery, PU tubing's resilience against repeated flexing and abrasion ensures reliable operation in high-speed environments, minimizing downtime due to hose failure.

Beyond general manufacturing, the properties of PU tubing lend themselves to more specialized fields. In the medical and laboratory sectors, certain grades of PU tubing are used for fluid transfer and pneumatic control in diagnostic equipment and analytical instruments, often requiring FDA compliance or specific biocompatibility. Its non-leaching properties and ability to withstand sterilization processes are critical. In the automotive industry, particularly in paint shops or assembly areas, PU tubing's resistance to solvents and paint overspray, coupled with its robust mechanical properties, provides reliable performance for pneumatic tools and air supply lines. For air conditioning systems in vehicles, specialized PU tubes offer excellent resistance to refrigerants and oils. The adaptability of high-quality PU tubing from experienced polyurethane tube manufacturers ensures dependable performance even in corrosive environments, offering a longer service life compared to alternative materials.

Strategic Selection: Choosing the Right Polyurethane Tube Manufacturer

Identifying a reputable polyurethane tube manufacturer involves more than just comparing price lists; it requires a deep dive into their capabilities, quality assurance, and customer support. A key indicator of expertise is a manufacturer's adherence to international quality management systems, such as ISO 9001:2015. This certification demonstrates a commitment to consistent quality and continuous improvement across all production stages. Furthermore, look for manufacturers who can provide comprehensive technical data, including detailed specifications for burst pressure, working temperature ranges, and chemical compatibility, validated by internal and third-party testing.

Beyond certifications, assess their experience in your specific industry. A pu tube factory with a proven track record in providing solutions for similar applications is more likely to understand your unique challenges and offer tailored advice. Inquire about their R&D capabilities, as innovation in material science and extrusion technology can lead to more durable, efficient, or application-specific products. Moreover, consider their commitment to environmental compliance, evidenced by certifications like RoHS or REACH, which are increasingly important for global supply chains. Ultimately, the right manufacturer acts as a long-term partner, contributing to the reliability and efficiency of your pneumatic systems.

Tailored Solutions: Customization Capabilities and Project Collaboration

Not all industrial applications can be satisfied with off-the-shelf tubing. Leading pu tube manufacturers offer extensive customization capabilities to meet highly specific performance requirements. This includes the production of tubes with custom outer and inner diameters, varying wall thicknesses, or specific multi-layer constructions to enhance pressure resistance or chemical compatibility. Color customization is also a common request, allowing for easy identification of different pneumatic lines within complex systems, which improves safety and simplifies maintenance.

Furthermore, specialized material formulations can be developed for extreme environments. For instance, tubes with enhanced UV resistance are crucial for outdoor applications, while anti-static or conductive PU tubes are vital in environments where static discharge could pose a hazard, such as electronics manufacturing or explosive atmospheres. Food-grade and medical-grade options are also available, adhering to stringent regulatory standards like FDA or USP Class VI. A dedicated pu tube factory capable of providing design consultation, prototyping services, and scaled production is an invaluable partner, enabling clients to develop innovative solutions precisely tailored to their unique operational demands and integrating seamlessly into their existing systems.

Ensuring Uncompromising Quality and Reliability: Certifications and Rigorous Testing

The cornerstone of reliable PU pneumatic hose lies in stringent quality control and comprehensive testing protocols. Reputable polyurethane tube manufacturers adhere to globally recognized standards such as ISO 9001 for quality management, ensuring consistency from raw material procurement to final product inspection. Environmental compliance certifications like RoHS and REACH also confirm the absence of hazardous substances, which is critical for global market access and environmental responsibility.

Beyond certifications, a robust testing regime is essential. This includes dimensional accuracy checks using laser micrometers to verify precise outer diameter, inner diameter, and wall thickness. Pressure testing, including both working pressure and burst pressure tests, evaluates the tube's integrity under various stress conditions. Abrasion resistance tests, often performed using methods like the Taber Abraser, simulate real-world wear to ensure long service life. Kink resistance, flexibility at low temperatures, and long-term creep resistance are also vital performance indicators that are rigorously assessed. Only through such comprehensive validation can a manufacturer confidently stand behind the durability and performance of their pu pneumatic hose. This meticulous attention to detail ensures that the delivered product meets or exceeds the demanding requirements of industrial applications, providing peace of mind to the end-user.

Frequently Asked Questions (FAQ) About Polyurethane Tubes

Q1: What are the primary advantages of PU tubing over Nylon or PVC tubing?

A1: PU tubing offers superior flexibility, excellent abrasion resistance, better kink resistance, and a wider operating temperature range. It also provides better memory (returns to original shape after bending) and generally has a longer service life in dynamic applications. Nylon is stiffer and can be brittle, while PVC is less durable and has a narrower temperature range.

Q2: How do I determine the correct size of PU pneumatic tube hose for my application?

A2: The correct size depends on the required flow rate, system pressure, and compatible fittings. Outer Diameter (OD) and Inner Diameter (ID) are critical. Consult flow charts and pressure drop calculations for your specific pneumatic system. It's always best to match the tubing size to your existing or planned fittings to ensure a secure, leak-free connection.

Q3: Can PU tubing be used with fluids other than compressed air?

A3: Yes, specific grades of PU tubing are compatible with various fluids, including water, certain oils, and chemicals. However, it is crucial to consult the manufacturer's chemical compatibility chart to ensure the chosen PU grade can withstand the specific fluid and operating conditions. Using incompatible fluids can lead to premature degradation and failure of the tube.

Q4: What is the typical service life of a PU pneumatic hose?

A4: The service life of PU pneumatic hose varies significantly based on operating conditions such as pressure, temperature, bending cycles, and exposure to chemicals or UV light. Under ideal conditions and within specified parameters, high-quality PU tubing can last for many years. Regular inspection for kinks, cracks, or discoloration is recommended to ensure optimal performance and safety.

Commitment to Excellence: Delivery, Warranty, and Customer Support

A key differentiator for top-tier polyurethane tube manufacturers extends beyond product quality to their commitment to client service. Efficient supply chain management is critical for B2B operations, meaning reliable manufacturers provide clear communication regarding lead times, order tracking, and flexible delivery options to minimize disruptions to your production schedule. For standard products, rapid dispatch is often available, while custom orders benefit from transparent project timelines and regular updates from the pu tube factory.

Furthermore, a comprehensive warranty policy underscores a manufacturer's confidence in their product's durability and performance. This typically covers material defects and manufacturing flaws for a specified period, offering peace of mind and protecting your investment. Beyond sales, dedicated technical support is invaluable. This includes expert assistance with product selection, troubleshooting, installation guidance, and post-sales inquiries. Accessible and responsive customer service ensures that any challenges are quickly addressed, reinforcing the partnership and ensuring the long-term success of your pneumatic systems.

Conclusion: Partnering for Pneumatic System Superiority

The selection of high-quality polyurethane tubing is a strategic decision that directly impacts the efficiency, reliability, and lifespan of pneumatic systems across diverse industrial applications. By prioritizing leading polyurethane tube manufacturers who demonstrate expertise in advanced manufacturing processes, adherence to stringent quality standards, and offer comprehensive customization capabilities, businesses can secure a competitive edge. The emphasis on technical precision, rigorous testing, and robust customer support ensures that every meter of PU Pneumatic tube Hose delivered is engineered for optimal performance and durability.

As industries continue to evolve towards more automated and precise operations, the demand for superior pneumatic components will only intensify. Partnering with a manufacturer committed to innovation and client satisfaction is not just about purchasing a product; it's about investing in a foundational element that drives operational excellence and safeguards your long-term success. Choose wisely, and empower your pneumatic systems with the best in polyurethane tubing technology.

Authoritative References

- ASTM D2240 – 15. (2015). Standard Test Method for Rubber Property—Durometer Hardness. ASTM International.

- ISO 9001:2015. (2015). Quality management systems — Requirements. International Organization for Standardization.

- RoHS Directive 2011/65/EU. (2011). Restriction of Hazardous Substances in Electrical and Electronic Equipment. European Parliament and Council.

- REACH Regulation (EC) No 1907/2006. (2006). Registration, Evaluation, Authorisation and Restriction of Chemicals. European Parliament and Council.

- ASM Handbook, Volume 21: Composites. (2001). ASM International.

-

Advanced Corrugated Pvc Hose Technology for Modern Industrial NeedsNewsAug.22,2025

-

Premium Fire Water Hose Solutions for Global IndustriesNewsAug.22,2025

-

Industrial Suppliers Guide to Premium Double Welding Hose SolutionsNewsAug.22,2025

-

Premium PU Pneumatic Hose Solutions for Industrial ApplicationsNewsAug.22,2025

-

Wholesale PVC Garden Hose China Solutions for Global BuyersNewsAug.22,2025

-

Wire Reinforced PVC Tubing Solutions for Global Industrial ApplicationsNewsAug.20,2025