лют . 15, 2025 08:07

Back to list

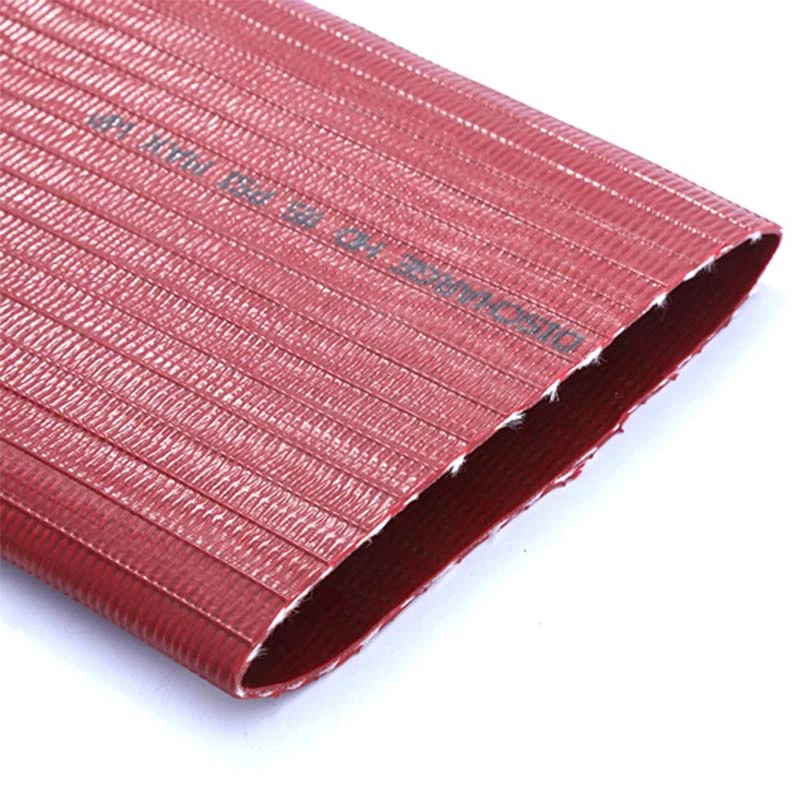

High Quality Light Weight Soft Ozone Resistance PVC Lining Fire Water Hose

The realm of polymer braided hoses is an captivating intersection of technology and everyday utility. These hoses, essential in diverse applications from automotive to industrial, combine the durability of polymers and the flexibility of braiding to create a robust, adaptable product. In an industry where performance and reliability are paramount, understanding the inner workings of polymer braided hoses can enhance user experience while offering indispensable expertise to potential users.

For those in the market for polymer braided hoses, understanding the available options and selecting the appropriate material is critical. Common materials include nylon, PTFE, and PVC, each offering distinct benefits. Nylon braided hoses are particularly prized for their high-pressure resistance and flexibility, making them ideal for automotive applications. PTFE, known for its superior temperature resistance and chemical inertness, is perfect for chemical processing environments. Meanwhile, PVC is a cost-effective option that balances performance and price, making it suitable for general home and garden use. Installation of polymer braided hoses is another area where expertise is crucial. Proper fitting and secure connections can mean the difference between seamless operation and frequent maintenance headaches. Ensuring that hoses are cut to the correct length, avoiding sharp bends, and maintaining appropriate tension during installation can prevent leaks and extend the hose's lifespan. Maintenance of these hoses should also be considered to maintain system integrity. Regular inspections can help identify wear and tear or potential weak points, reducing the risks of unexpected failures. Trust in polymer braided hoses is built through adherence to regulatory standards and quality certifications. Products that meet international standards such as ISO or SAE reassure users of their reliability and performance. Additionally, manufacturers who invest in rigorous testing and quality control procedures ensure that their hoses meet the stringent demands of high-performance environments. Ultimately, polymer braided hoses represent a sophisticated solution for a range of applications, combining durability with flexibility, and performance with cost-effectiveness. By understanding the specific requirements of their application, users can select the most appropriate hoses, benefiting from their advanced engineering and reliability. Whether it's for industrial, automotive, or domestic use, polymer braided hoses offer a compelling blend of technology and practicality, positioning themselves as indispensable tools in the modern world.

For those in the market for polymer braided hoses, understanding the available options and selecting the appropriate material is critical. Common materials include nylon, PTFE, and PVC, each offering distinct benefits. Nylon braided hoses are particularly prized for their high-pressure resistance and flexibility, making them ideal for automotive applications. PTFE, known for its superior temperature resistance and chemical inertness, is perfect for chemical processing environments. Meanwhile, PVC is a cost-effective option that balances performance and price, making it suitable for general home and garden use. Installation of polymer braided hoses is another area where expertise is crucial. Proper fitting and secure connections can mean the difference between seamless operation and frequent maintenance headaches. Ensuring that hoses are cut to the correct length, avoiding sharp bends, and maintaining appropriate tension during installation can prevent leaks and extend the hose's lifespan. Maintenance of these hoses should also be considered to maintain system integrity. Regular inspections can help identify wear and tear or potential weak points, reducing the risks of unexpected failures. Trust in polymer braided hoses is built through adherence to regulatory standards and quality certifications. Products that meet international standards such as ISO or SAE reassure users of their reliability and performance. Additionally, manufacturers who invest in rigorous testing and quality control procedures ensure that their hoses meet the stringent demands of high-performance environments. Ultimately, polymer braided hoses represent a sophisticated solution for a range of applications, combining durability with flexibility, and performance with cost-effectiveness. By understanding the specific requirements of their application, users can select the most appropriate hoses, benefiting from their advanced engineering and reliability. Whether it's for industrial, automotive, or domestic use, polymer braided hoses offer a compelling blend of technology and practicality, positioning themselves as indispensable tools in the modern world.

Latest news

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

HOT PRODUCT

Provide You The Highest Quality Work

INQUIRE