oxy acetylene hose 100 ft

Understanding Oxy-Acetylene Hoses A Closer Look at the 100 ft Variant

Oxy-acetylene welding is one of the most commonly used techniques in metal fabrication and construction. This process requires a combination of oxygen and acetylene gases in order to produce a flame that can reach extremely high temperatures, sufficient for melting and fusing metals. A crucial component of the oxy-acetylene setup is the hose that carries these gases from their respective cylinders to the torch. Among the various options available in the market, the oxy-acetylene hose measuring 100 feet in length has gained popularity among professionals and enthusiasts alike.

What is a 100 ft Oxy-Acetylene Hose?

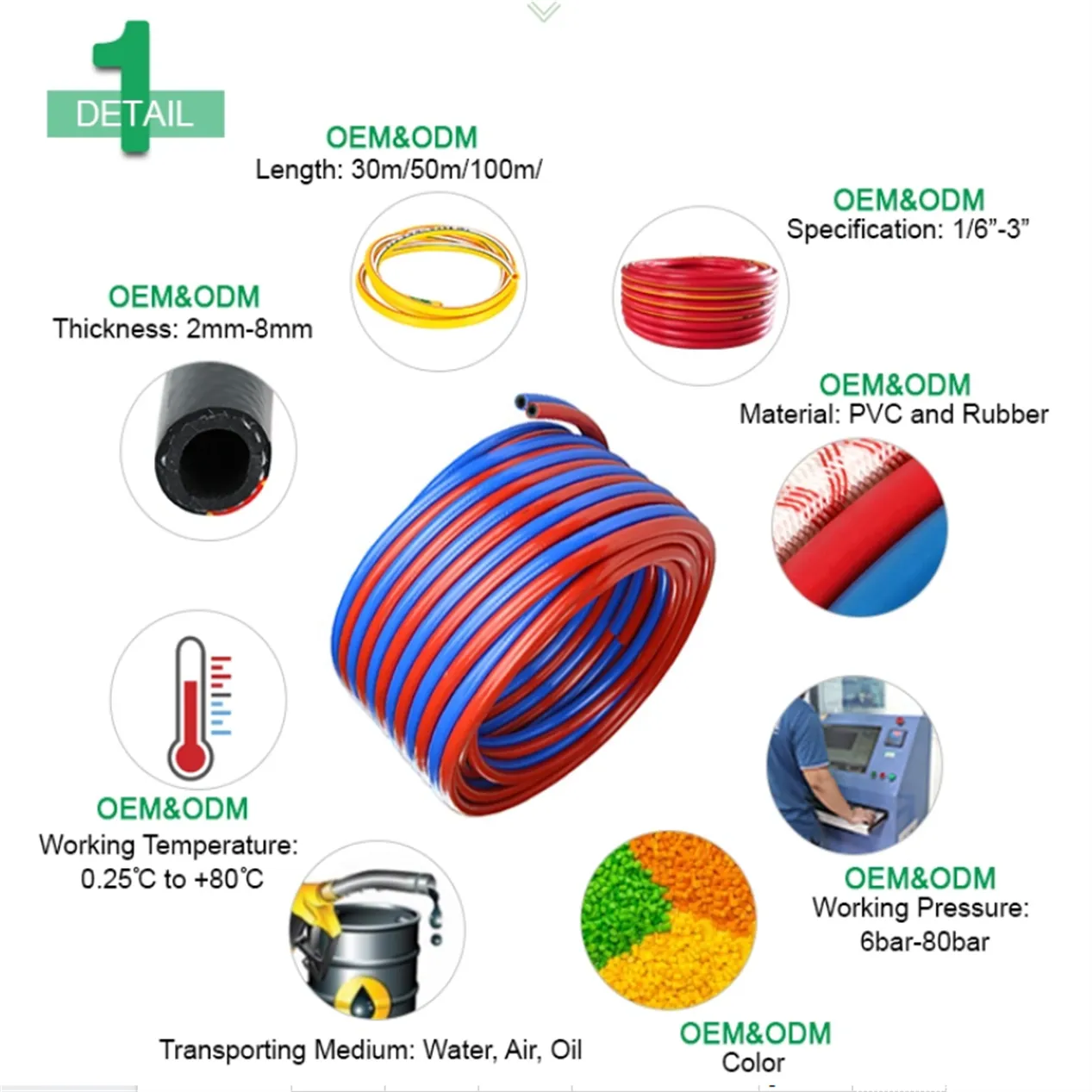

A 100 ft oxy-acetylene hose refers to a pair of hoses, one for oxygen and the other for acetylene, each measuring 100 feet. These hoses are designed to withstand the demands of welding and cutting operations. Made from durable materials, they offer excellent flexibility and resistance to heat, abrasion, and chemical damage. They are typically color-coded the oxygen hose is green, while the acetylene hose is red, allowing users to easily identify each gas and avoid dangerous mix-ups.

Benefits of a 100 ft Oxy-Acetylene Hose

1. Enhanced Mobility With a length of 100 feet, welders can maneuver around a worksite more freely without the need to constantly reposition gas cylinders. This extended reach is especially advantageous in large projects or when working in confined spaces.

2. Versatility in Applications A 100 ft hose is ideal for various applications, including welding, cutting, brazing, and heating. This versatility makes it a valuable tool for both professional welders and DIY enthusiasts tackling projects at home.

3. Reduced Setup Time Longer hoses can minimize the time spent rearranging equipment. This efficiency not only saves time but also reduces the risk of wear and tear on the hoses from frequent movement.

oxy acetylene hose 100 ft

4. Safety Features Quality oxy-acetylene hoses come with safety features such as flame-resistant materials and built-in check valves to prevent backflow, ensuring protection against potential hazards associated with gas leaks and uncontrolled flames.

Proper Use and Maintenance

To ensure both safety and longevity of your 100 ft oxy-acetylene hose, proper use and maintenance are essential. Here are some tips

- Routine Inspection Regularly inspect hoses for cracks, frays, or leaks. Any signs of wear should prompt immediate replacement to prevent dangerous situations. - Secure Connections Always check that the connections to the torch and the gas cylinders are secure. Loose connections may lead to gas leaks, which can be hazardous.

- Proper Storage When not in use, store hoses coiled and out of direct sunlight to avoid damage. Avoid storing them near sources of heat or chemicals that could degrade the materials.

- Follow Manufacturer Guidelines Adhering to the manufacturer's specifications for pressure ratings and operating procedures is crucial for safe and effective use.

Conclusion

In summary, a 100 ft oxy-acetylene hose is an indispensable tool for anyone engaged in welding and metalworking tasks. Its enhanced mobility, versatility, and safety features make it an excellent choice for professionals and hobbyists alike. By understanding the proper use and maintenance of these hoses, users can ensure a safe and efficient welding experience, ultimately leading to greater productivity and success in their projects. Whether you are in a fabrication shop or working on a DIY project at home, investing in a quality 100 ft oxy-acetylene hose can greatly enhance your welding capabilities.

-

Unrivaled Utility of PVC Flexible and Transparent HosesNewsJun.03,2025

-

The Power and Utility of Specialized Hoses in Diverse ApplicationsNewsJun.03,2025

-

The Essential Role and Versatility of PVC Transparent HosesNewsJun.03,2025

-

Reinforced Hoses: Engineering Excellence for Diverse ApplicationsNewsJun.03,2025

-

Garden Irrigation Solutions: A Comprehensive Look at Flexible HosesNewsJun.03,2025

-

Garden Hydration Solutions: A Comprehensive Guide to Essential HosesNewsJun.03,2025