vacuum pump hose

Understanding Vacuum Pump Hoses A Key Component in Industrial Applications

Vacuum pump hoses play a crucial role in various industrial and scientific applications where the creation of a vacuum is necessary. These hoses are designed to transport air, gases, or liquids in a vacuum environment, ensuring that systems maintain the required pressure levels to function optimally.

What is a Vacuum Pump Hose?

A vacuum pump hose is a flexible tube used to connect a vacuum pump to other equipment or vessels. It is engineered to withstand the pressure differentials that occur during the vacuum process. Typically made from high-quality materials such as rubber, silicone, or reinforced plastics, these hoses are specifically designed to prevent leaks that could compromise the vacuum system's efficiency.

Types of Vacuum Pump Hoses

There are several types of vacuum pump hoses available, each tailored to specific needs and conditions

. Common varieties include1. Rubber Vacuum Hoses These are commonly used due to their flexibility and durability. They can handle a range of temperatures and are resistant to various chemicals, making them suitable for many environments.

2. Silicone Vacuum Hoses Known for their excellent temperature tolerance and chemical resistance, silicone hoses are ideal for applications requiring high purity, such as in the pharmaceutical and food industries.

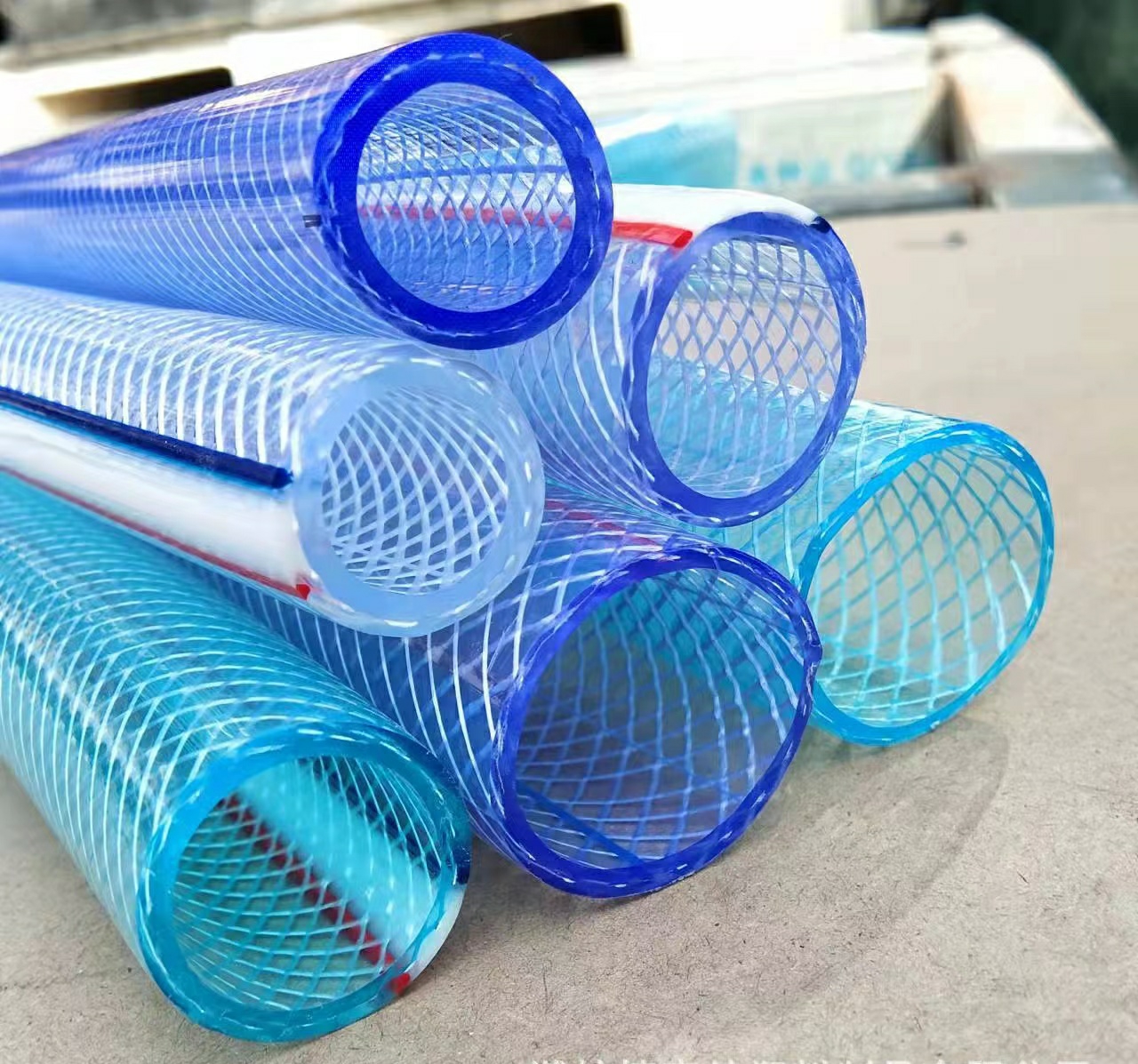

3. Reinforced PVC Hoses These hoses provide added strength and durability, making them suitable for high-vacuum applications. Their transparency also allows for easy monitoring of the flow within the hose.

vacuum pump hose

4. Stainless Steel Hoses For extreme environments, stainless steel hoses provide exceptional durability and resistance to corrosion. They are often used in applications involving harsh chemicals or extreme temperatures.

The Importance of Proper Hose Selection

Choosing the right vacuum pump hose is critical for the effectiveness of a vacuum system. Factors to consider include

- Pressure Ratings Ensure that the hose can withstand the specific pressure conditions of your vacuum system. - Chemical Compatibility The materials used in the hose should be compatible with any substances they will encounter, to prevent degradation or failure. - Temperature Range The hose must be able to handle the temperature extremes of the system, both at operational levels and during any potential failures.

Maintenance and Care

Regular maintenance of vacuum pump hoses is essential to prolong their lifespan and ensure optimal performance. Inspect hoses for signs of wear, such as cracks, bulges, or kinks, which can indicate impending failure. Additionally, ensure all connections are tight to prevent leaks, and clean hoses as needed to avoid contamination.

Conclusion

Vacuum pump hoses are indispensable components in many applications, from scientific research to industrial manufacturing. By understanding their types, importance, and maintenance requirements, users can ensure their systems operate effectively and efficiently. Choosing the right hose can make a significant difference in performance and longevity, ultimately leading to better results in any vacuum-related tasks.

-

Top Quality Oxy Acetylene Hoses for Sale Fit for Welding DemandsNewsJul.28,2025

-

The Future of Pneumatic Air Tubes in IndustryNewsJul.28,2025

-

Superior and Reliable LPG Hose Pipe Solutions for Every NeedNewsJul.28,2025

-

Exceptionally Durable and Versatile Premium Braided PVC TubingNewsJul.28,2025

-

Best Adapters for Connecting Garden Hose to PVC Pipe ConnectionsNewsJul.28,2025

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025